4

inside surfaces. Check belt tension by using a spring--force

tool (such as Browning’s Part Number “Belt Tension

Checke r” or equivale nt tool); tension should be 6--lbs at a

5/8--in. deflection when measured at the centerline of the

belt span. This point is at the center of the belt when

mea suring the distance between the motor shaft and the

blower shaft.

NOTE: Without the spring--tension tool, place a straight

edge across the belt surface at the pulleys, then deflect the

belt at mid--span using one finger to a 1/2--in. deflec tion.

Adjust belt tension by loosening the motor mounting plate

front bolts and re ar bolt and slidi ng the plate toward the

fan (to reduce tension) or away from fan (to increase

tension). Ensure the blower shaft and the motor shaft are

parallel to each other (pulleys aligned). Tighten all bolts

when finished.

To replace the belt:

1. Use a belt with same section type or similar size. Do

not substitute a “FHP” type belt. When installing the

new belt, do not use a tool (screwdriver or pry--bar) to

force the belt over the pulley flanges, this will stress

the belt and cause a reduction in belt life.

2. Loosen the motor mounting plate front bolts and rear

bolts.

3. Push the motor and its mounting plate towards the

blower housing as close as possible to reduce the cen-

ter distance between fan shaft and motor shaft.

4. Remove the belt by gently lifting the old belt over

one of the pulleys.

5. Install the new belt by gently sliding the belt over

both pulleys and then sliding the motor and plate

away from the fan housing until prope r tension i s

achi eved.

6. Check the alignment of the pulleys, adjust if neces-

sary.

7. Tighten all bolts.

8. Check the tension after a few hours of runtime and

re--adjust as required.

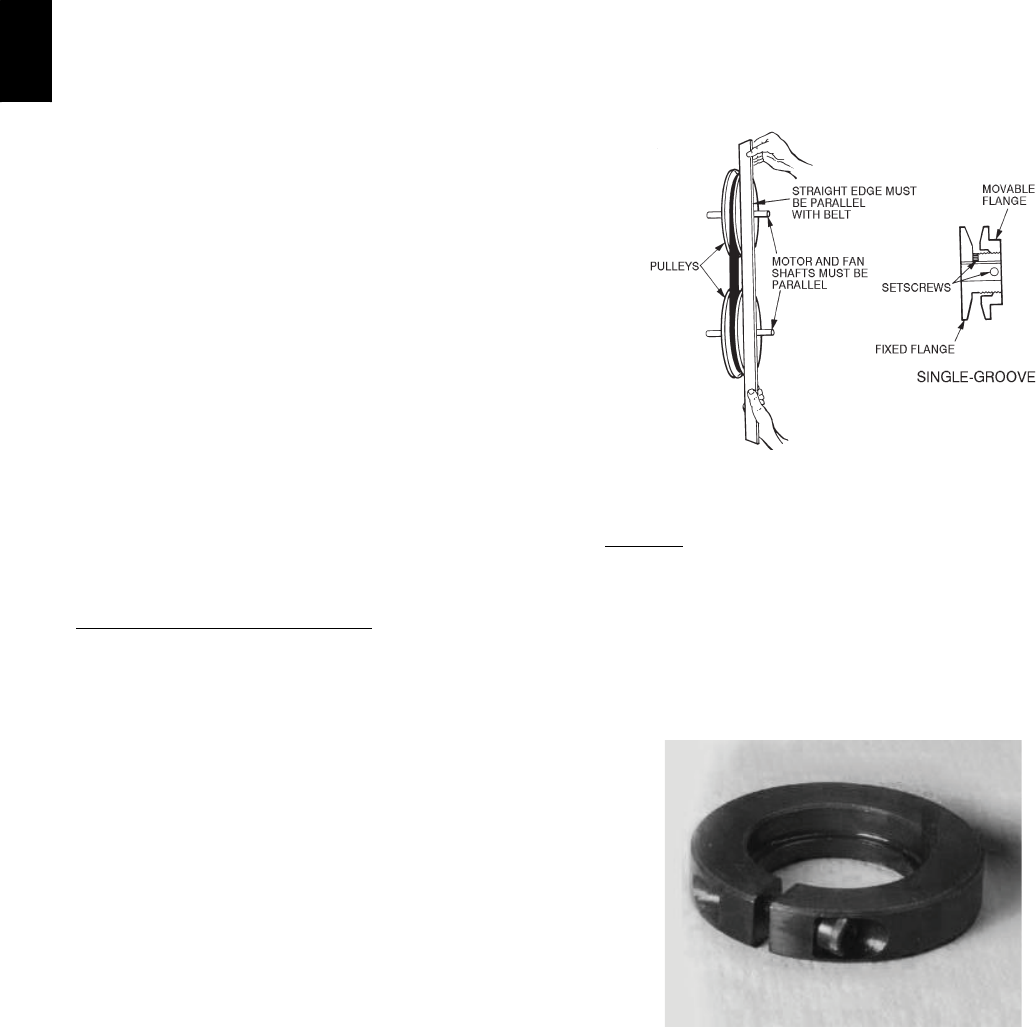

Adjustable--Pitch Pulley on

Motor

The motor pulley is an adjustable--pi tch type that allows a

servicer to implement changes in the fan wheel speed to

match as--installed ductwork systems. The pulley consists

of a fixed flange side that faces the motor (secured to the

motor shaft) and a movable flange side that can be rotated

around the fixed flange side that increases or reduces the

pitch diameter of this driver pulley. (See Fig. 6.)

As the pitch diameter is changed by adjusting the position

of the movable flange, the centerline on this pulley shifts

laterally (along the motor shaft). This creates a

requirement for a realignment of the pulleys after any

adjustment of the movable flange. Also reset the belt

tension after each realignment.

Check the condition of the motor pulley for signs of wear.

Glazing of the belt contact surfaces and erosion on these

surfaces are signs of improper belt tension and/or belt

slippage. Pulley replacement may be necessary.

To change fan speed:

1. Shut off unit power supply.

2. Loosen belt by loosening fan motor mounting nuts.

(See Fig. 5.)

3. Loosen movable pulley flange setscrew. (See Fig. 6.)

4. Screw movable flange toward fixed flange to increase

speed and away from fixed flange to decrease speed.

Increasing fan speed increases load on motor. Do not

exceed maximum speed specified.

5. Set m ovable flange at nearest keyway of pulley hub

and tighten setscrew to torque specifications.

To align fan and motor pulleys:

1. Loosen fan pulley setscrews.

2. Slide fan pulley along fan shaft. Make angular align-

ment by loosening motor from mounting.

3. Tighten fan pulley setscrews and motor mounting

bolts to torque specifications.

4. Recheck belt tension.

C07075

Fig. 6 -- Supply--Fan Pulley Adjustment

Beari ngs

This fan system uses bearings featuring concentric split

locking collars. The collars are tightened through a cap

screw bridgi ng the split portion of the collar. The cap

screw has a Torx T25 socke t head. To tighten the locki ng

collar: Hold the locking collar tightly against the inner

race of the bearing and torque the cap screw to 65--70

in--lb (7.4--7.9 Nm). See Fig. 7.

C08121

Fig. 7 -- Tightening Locking Collar

50TC