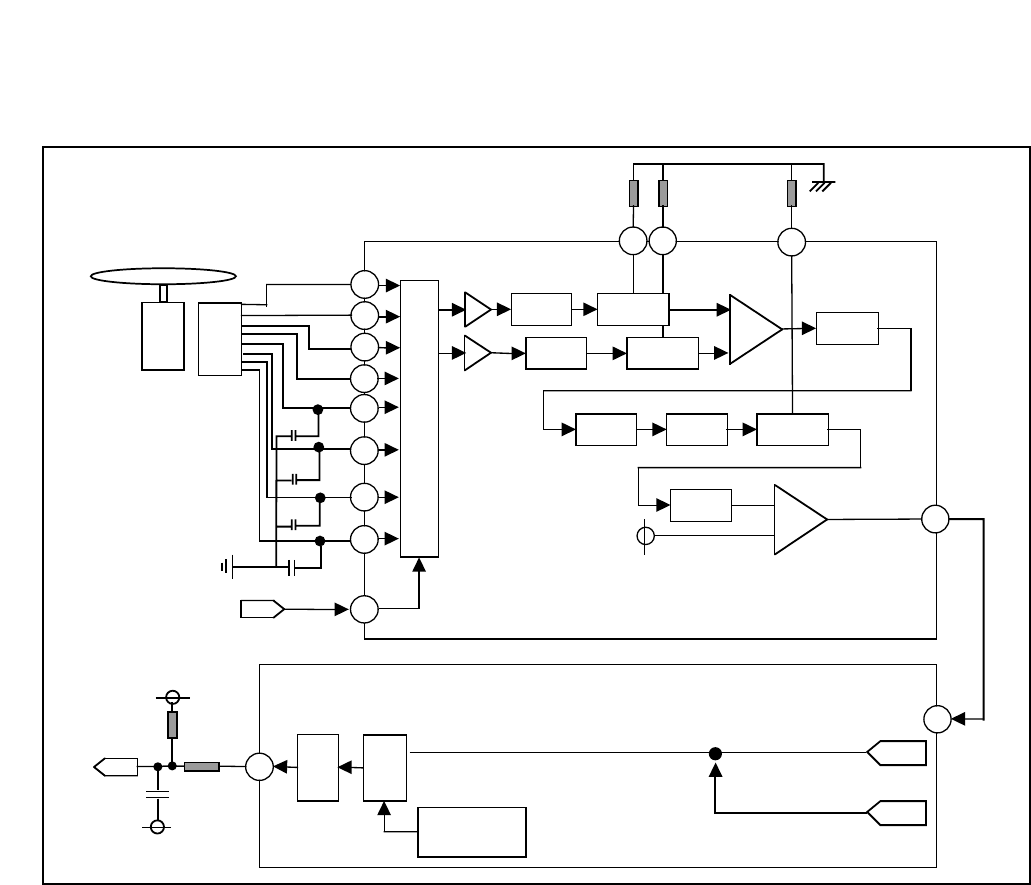

4-2-1. Block Diagram (Wobble CLV Servo)

54

Disc

Motor uni

t

Optical

Pick-up

HOP-7632TS

IC101

R2S35002

HPF

S

/

H

-

+

C174

C173

C171

C172

WBLSH

C116

87

88

89

90

92

93

94

95

HPF AGC2

HPFBPF AGC3

HPF

HPF

37

31

WBLS

GND

H

18 19

AGC1

20

VREF

WAG1 WAG2 WAG3

SA

SB

SC

SD

MA

MB

MC

MD

+

-

C117 C118

ADO

BCO

IC301

R8J32007

M

U

X

P

W

M

SPD

PH

SP

211

Motor Kick

REG

154

R349

R375

C349

1.65V

1.65V

SPD

WOBSIG

4-2-2. Wobble CLV Servo

CD-R : 4x, 8x, 16x, 24x, 32x, 40x, 48x

/CD-RW : 4x, 10x, 16x, 24x, 32x

/DVD-R : 2x, 4x, 8x, 16x(PCAV)

/DVD-R DL : 2x, 4x

/DVD-RW : 1x, 2x, 4x, 6x

/DVD+R : 2.4x, 4x, 8x, 12x, 16x(PCAV)

/DVD+R DL : 2.4x, 4x, 6x

/DVD-RAM : 2x, 3x, 3-5x(PCAV)

/DVD+RW : 2.4x, 4x, 8x

When drive write DVD-RAM/R/RW/+R/+RW/CD-R/CD-RW, the spindle motor is controlled using Wobble CLV

Spindle Servo.

The WOBSIG signal(R2S35002 37pin) input to DSP IC(R8J32007 154pin). The DSP Controller in R8J32007

uses WOBSIG as linear velocity feed back, therefore the Wobble CLV Spindle Servo doesn’t work well when

WOBSIG signal is abnormal.

The spindle controller PWM output signal SPD (R8J32007 211pin) input to SPIN in Drive IC(R2S30202FP 1pin)

after Low-Pass Filtering.

The PWM output signal U,V, W signal(R2S30202FP 12, 13, 14pin) drives Spindle Motor without using a sensor.