General Troubleshooting & Service Teledyne API T703/T703U Calibrator Operation Manual

176

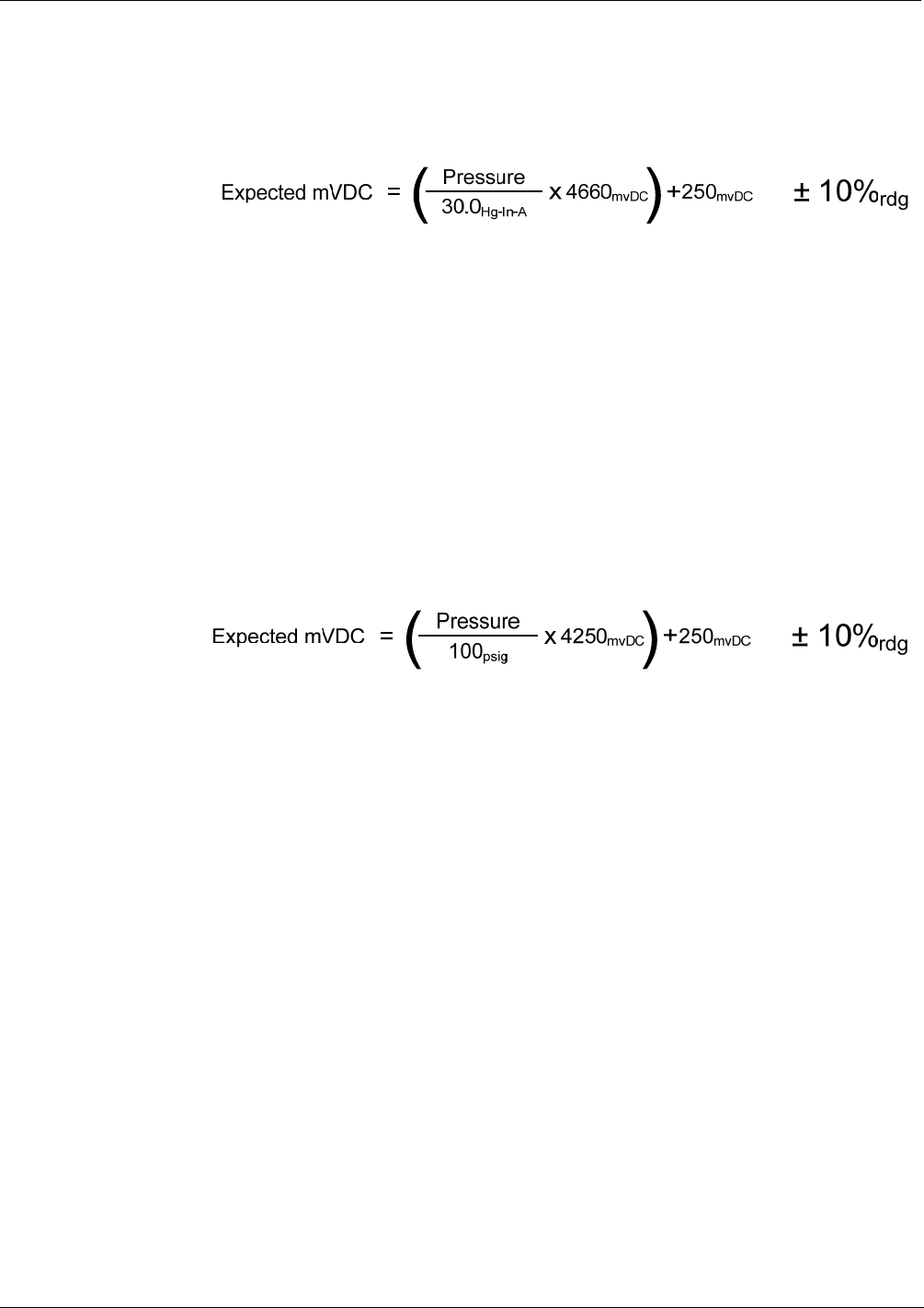

PHOTOMETER PRESSURE SENSOR (ABSOLUTE PRESSURE):

1. Measure the pressure on the inlet side of S1 with an external pressure meter.

2. Measure the voltage across TP4 and TP1.

The expected value for this signal should be:

EXAMPLE: If the measured pressure is 20 Hg-in-A, the expected voltage level between

TP4 and TP1 would be between 2870 mVDC and 3510 mVDC.

EXAMPLE: If the measured pressure is 25 Hg-in-A, the expected voltage level between

TP4 and TP1 would be between 3533 mVDC and 4318 mVDC.

If this voltage is out of range, then either pressure transducer S1 is bad, the

board is bad or there is a pneumatic failure preventing the pressure transducer

from sensing the absorption cell pressure properly.

O

3

GENERATOR PRESSURE SENSOR (GAUGE PRESSURE):

1. Measure the pressure on the inlet side of S2 with an external pressure meter.

2. Measure the voltage across TP5 and TP1.

The expected value for this signal should be:

EXAMPLE: If the measured pressure is 25 psig, the expected voltage level between

TP4 and TP1 would be between 1182 mVDC and 1444 mVDC.

EXAMPLE: If the measured pressure is 30 psig, the expected voltage level between

TP4 and TP1 would be between 1373 mVDC and 1677 mVDC.

If this voltage is out of range, then either pressure transducer S1 is bad, the

board is bad or there is a pneumatic failure preventing the pressure transducer

from sensing the absorption cell pressure properly.

PHOTOMETER FLOW SENSOR:

Measure the voltage across TP3 and TP1.

With proper flow (800 cc

3

/min through the photometer), this should be

approximately 4.5V (this voltage will vary with altitude).

With flow stopped (photometer inlet disconnected or pump turned OFF) the

voltage should be approximately 1V.

If the voltage is incorrect, the flow sensor S3 is bad, the board is bad or there is

a leak upstream of the sensor.

07223C DCN6572