17

12. Once proper contact has been assured,

use the following procedure to tighten the

locknuts and secure the lockwasher tabs.

12.1. Back off both locknuts and the lock-

washer on one side of the cam.

12.2. Apply Green Perma-Lok‚ to the

threads on the input shaft.

12.3. Use a Spanner Wrench that has been

locked (jammed) against the top or bot-

tom of the housing to hold the locknut

while turning the input shaft. Use the

motor drive package to rotate the input

shaft and tighten the locknut.

12.4. Repeat the previous step to tighten

the second locknut on the same side of

the cam.

WARNING

CAMCO’s Heavy Duty "E" Series Index Drives

cannot be "hand cranked" when completely

assembled, i.e. with follower wheel installed.

During some portions of repair, the motor

drive package is used to rotate the input shaft

and follower wheel. Some means for running

the motor at extremely low speeds is manda-

tory. Use extreme caution when operating the

motor during repairs.

13. Bend over the lockwasher tabs towards

the locknut and into the slot.

CAUTION

A torque specification for locknuts is not avail-

able. Make sure they are tight!

14. Repeat the above steps and tighten the

locknuts on the opposite side of the cam.

15. After tightening locknuts, re-apply

Prussian Blue and check for tip relief etc.

FOLLOWER WHEEL AND/OR

OUTPUT BEARING REPLACEMENT:

FOLLOWER WHEEL REMOVAL:

In most cases, the follower wheel and/or out-

put bearing cannot be removed without

removing the major portion of any support

structure and fixtures. An overhead crane or

similar device must be used to lift the follower

wheel and output bearing. In some cases, the

support structure and fixtures can be lifted

two to three feet above the unit and support-

ed by appropriate scaffolding. The follower

wheel and output bearing can then be

removed with a boom crane or similar device.

CAMCO recommends using professional

machinery riggers for this purpose. The

assistance of a CAMCO trained serviceman

is recommended.

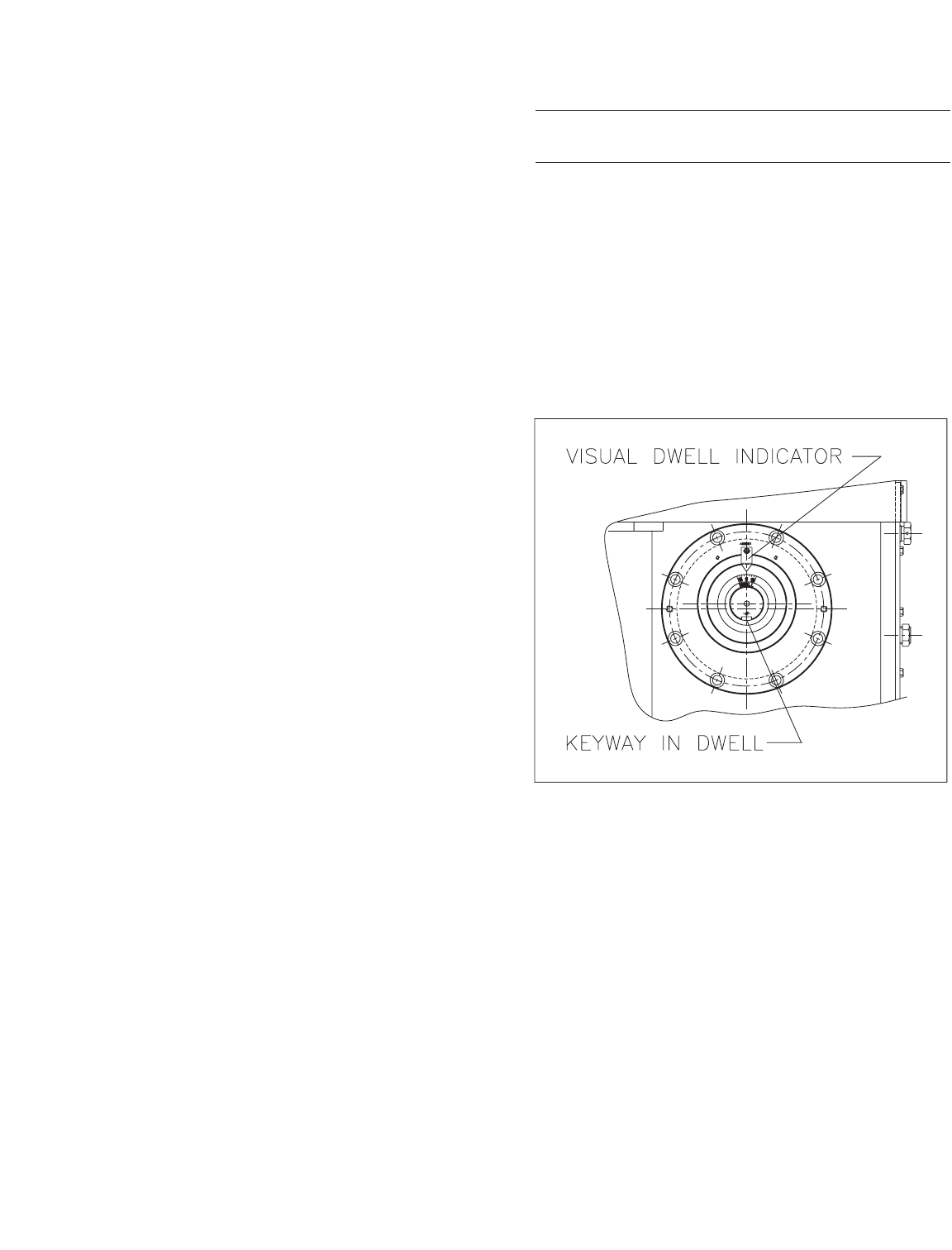

1. Use the motor drive package to position

the input shaft keyway such that the cam is

just entering dwell.

Note: For most Camco E-Series Index Drives

this is ten to fifteen (10˚ - 15˚) degrees clock-

wise or counter-clockwise from the mid-dwell

position.

DWELL POSITION, E-SERIES INDEX DRIVES