7.2. Heat a new Bearing Cone in a commer-

cial bearing oven that has been designed

for this purpose. Heat evenly to about

250˚F.

7.3. Alternatively, heat the bearing with a

heat gun.

WARNING

Use protective gloves while handling bearings

after they have been heated in an oven.

7.4. Using a twisting motion of the hand,

push the Bearing Cone against the shoul-

der on the input shaft.

CAUTION

Make sure the bearing is seated against the

shaft shoulder. Improper mounting of the

bearing can cause premature failure.

7.5. If the bearing does not immediately

seat against the shaft shoulder, use a

piece of tubing over the shaft and

against the bearing, and a soft hammer

to drive the bearing against the shoulder.

8. Use an Arbor Press to press the bearing

cups to the input cartridges.

8.1. Coat the outside of the bearing cup

with anti-seize lubricant prior to pressing

into cartridge.

9. Re-install the bearing cartridges.

9.1. Use duplicate shims to those previ-

ously removed, but adjust the shims for

the measured height of the bearings.

9.2. Apply a small bead of "General Electric

Silicone Rubber RTV-6" at the intersec-

tion of the pilot diameter and flange

before installing the bearing cartridges.

10. Install new oil seals. See section titled

"Oil Seal Replacement" in this Service

Manual for detailed instructions.

11. Check for input shaft endplay.

11.1. Endplay in the input shaft is not

permissible. There should be preload on

the input bearings. Use a dial indicator

and a pry bar to check for endplay.

11.2. Heavier preload is preferred to end-

play. Remove input shim if end play is

detected.

11.3. With just the input shaft, cam and oil

seals installed, preload can be measured

with a torque wrench. An adapter

between the input shaft and torque

wrench is required, and the torque

wrench must be capable of measured

torque values up to 6000 in-lbs. See the

table titled "Input Preload Torque" in this

Service Manual.

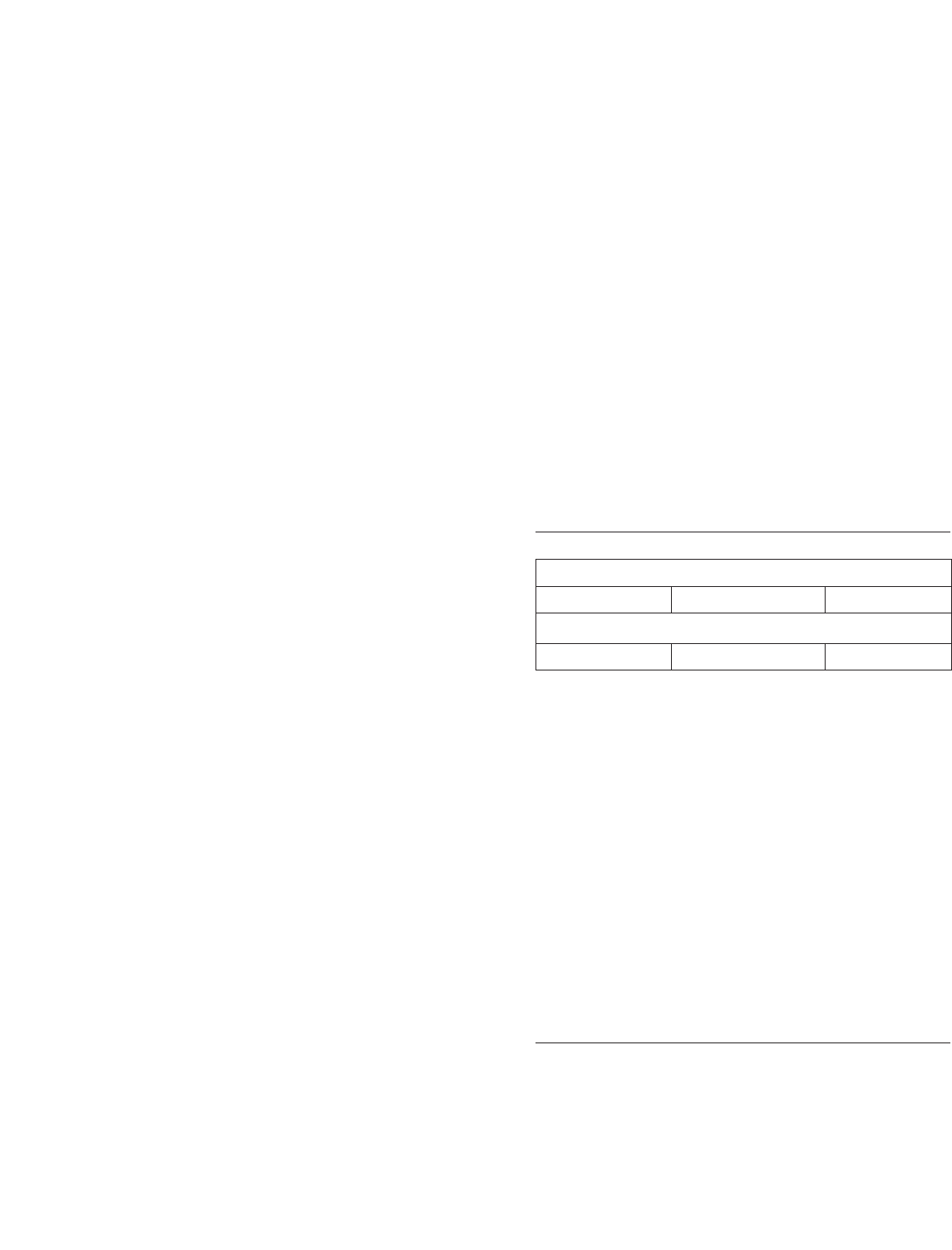

INPUT PRELOAD TORQUE:

Camco E-Series Index Drive

950E 1150E & 1550E 2050E

Input Preload Min.–Max.(in-lbs)

500 - 2000 1000 – 4000 2000 - 6000

CAUTION

End play in the input shaft will cause

premature failure of the Index Drive.

12. Re-install the reducer and any portion of

the drive package that was previously

removed.

CAUTION

Make sure the hollow shaft of the reducer and

the input shaft is properly aligned.

Misalignment of the reducer and input shaft

will cause premature failure of the Index Drive.

SETTING CAM:

1. Install a dowel pin in the hole provided in

the upper wall of the housing. The diame-

ter varies depending on which E-Series

Index Drive is being repaired. Polish the

dowel pin as necessary to provide a slip fit

into the hole.

15