Dosing Options

3A0869H 51

Dosing Options

Sequential Dosing

Components A and B dispense sequentially in the nec-

essary volumes to attain the mix ratio.

1. The operator presses

to begin operation.

2. The ProMix 2KE controller sends signals to activate

the solenoid valves. The solenoid valves activate

Dose Valves A1 (A2 or A3, depending on recipe

selection) and B. Fluid flow begins when the gun is

triggered.

3. Components A1 and B are introduced into the fluid

integrator (FI) one at a time as follows.

a. The A side dose valve (DVA1, DAV2, or DVA3)

opens, and fluid flows into the integrator.

b. Flow Meter A (MA) monitors the fluid volume

dispensed and sends electrical pulses to the

ProMix 2KE controller. The controller monitors

these pulses and signals.

c. When the target volume dispenses, Dose Valve

A closes.

NOTE: The dispense volume of component A and B

is based on the mix ratio and dose size set by the

user and calculated by the ProMix 2KE controller.

d. Dose Valve B (DVB) opens, and fluid flows into

the integrator and is aligned proportionately with

component A.

e. Flow Meter B (MB) monitors the fluid volume

dispensed and sends electrical pulses to the

ProMix 2KE controller.

f. When the target volume is dispensed, Dose

Valve B closes.

4. The components are pre-mixed in the integrator,

then uniformly blended in the static mixer (SM).

NOTE: To control output from the static mixer to the

gun, install an optional fluid pressure regulator.

5. Components A and B are alternately fed into the

integrator as long as the gun is triggered.

6. If the gun is not triggered for two minutes, the sys-

tem switches to Idle mode, which closes off the mix

manifold dose valves.

7. When the gun is triggered again, the ProMix 2KE

continues the process where it left off.

NOTE: Operation can be stopped at any time by

pressing or shutting off the main power

switch.

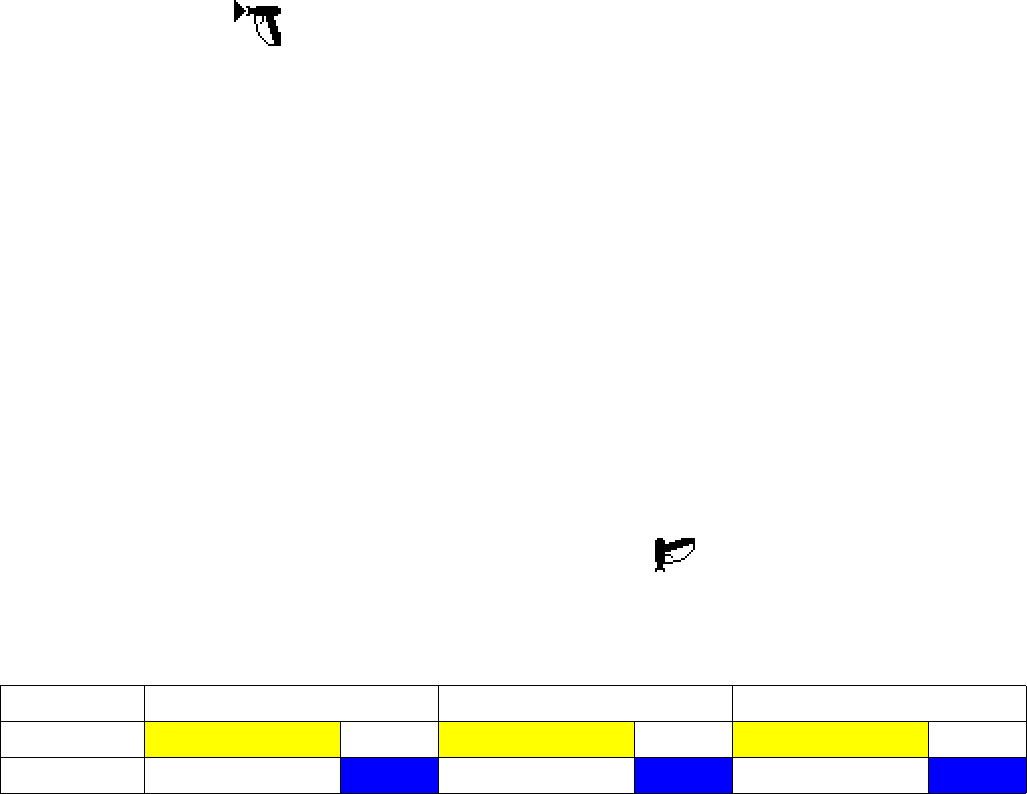

Table 3: Sequential Dosing Operation

Ratio = 2.0:1 Dose 1 Dose 2 Dose 3

A = 2

B = 1