SPYDER® BACNET® PROGRAMMABLE CONTROLLERS

19 63-2689—05

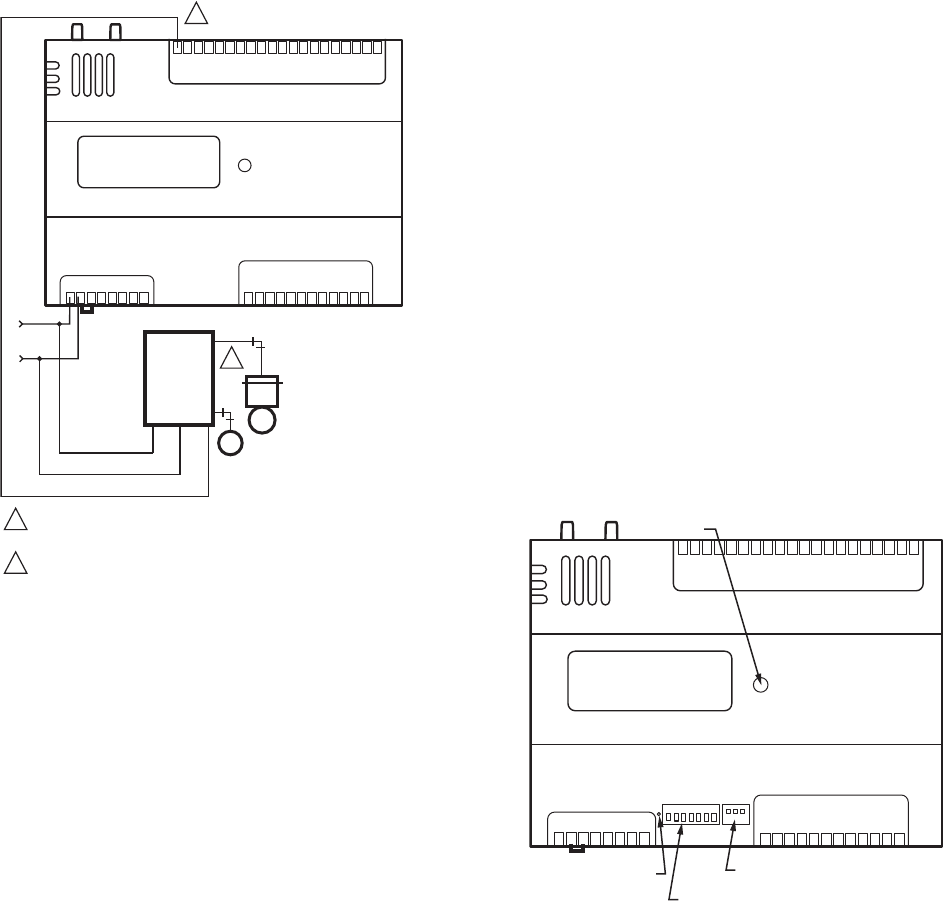

Fig. 22. Controller wiring diagram (model PUB6438S

shown) for RP7517B pneumatic transducer.

CHECKOUT

Step 1. Check Installation and Wiring

Inspect all wiring connections at the controller terminals, and

verify compliance with installation wiring diagrams. If any wiring

changes are required, first be sure to remove power from the

controller before starting work. Pay particular attention to:

— 24 Vac power connections. Verify that multiple controllers

being powered by the same transformer are wired with the

transformer secondary connected to the same input

terminal numbers on each controller. Use a meter to

measure 24 Vac at the appropriate terminals (see Fig. 12

on page 9). Controller configurations are not necessarily

limited to three devices, but the total power draw, including

accessories, cannot exceed 100 VA when powered by the

same transformer (U.S. only).

— Be sure that each controller has terminal 3 wired to a

verified earth ground, using a wire run as short as possible

with the heaviest gauge wire available, up to 14 AWG (2.0

sq mm) with a minimum of 18 AWG (1.0 sq mm) for each

controller in the group (see Fig. 12 on page 9).

— Check that the MS/TP network polarity has been connected

properly on each controller. BACnet MS/TP is polarity

sensitive; communication will be lost for the entire segment

if one controller is connected improperly (see Fig. 13 on

page 11).

— Verify that Triac wiring of the digital outputs to external

devices uses the proper load power and 24 Vac common

terminal (digital output common terminals) for High-Side

switching.

NOTE: All wiring must comply with applicable electrical

codes and ordinances or as specified on installa-

tion wiring diagrams.

For guidelines for wiring run lengths and power budget, see

“Power” on page 6.

VERIFY END-OF-LINE TERMINATION RESISTOR

PLACEMENT

The installation wiring diagrams should indicate the locations

for placement of the end of line termination resistors. See

Fig. 13 on page 11.

Correct placement of the end-of-line termination resistors is

required for proper L

ONWORKS® Bus communications.

Step 2. Startup

Refer to Fig. 23 and the following text for startup information.

Fig. 23. LED, service, and network connection locations.

SET THE MS/TP MAC ADDRESS

The MS/TP MAC address DIP switches are used to set the

unit's MAC address. Each Spyder BACnet on an MS/TP

network must have a unique MAC address in the range of 0-

127 (address 0 should be avoided as it is the Honeywell factory

default MAC address for all MS/TP devices).

CONTROLLER STATUS LED:

The LED on the front of the controller provides a visual

indication of the status of the device. When the controller

receives power, the LED appears in one of the following

allowable states, as described in Table 8.

AO-1

COM

AO-2

AO-3

COM

UI-1

COM

UI-2

UI-3

COM

UI-4

UI-5

COM

UI-6

DI-1

DI-2

COM

DI-3

20V DC

DI-4

NET-2

NET-1

SHLD

EGND

24 VAC

24VAC COM

DO-1

COM

DO-2

DO-3

DO-4

DO-5

COM

DO-6

COM

1

2

3456

78

109 2345678 09

11 1111111 21

1

2

34

5

6

78

0

9

22 2222222 33

1

2

34

5

6

78

0

9

333333334

M29339B

24 VAC

AO1

24 VAC

COM

1

2

USE 1/4 IN (6 MM) PNEUMATIC TUBING. MINIMUM BRANCH LINE

MUST BE 6 FT. (1.8M) OR LONGER.

TERMINALS 21, 23, AND 24 ARE ANALOG OUTPUTS.

+

-

BLUE

BLACK

BROWN

PNEUMATIC

VALVE

ACTUATOR

RP7517B

1M

2B

M

2

1

DO-7

DO-8

COM

SBUS1

SBUS2

BACnet MS/TP MAC

ADDRESS DIP SWITCHES

TERMINALS 1-8

TERMINALS 9-20

TERMINALS 21-40

AO-1

COM

AO-2

AO-3

COM

UI-1

COM

UI-2

UI-3

COM

UI-4

UI-5

COM

UI-6

DI-1

DI-2

COM

DI-3

20V DC

DI-4

NET-2

NET-1

SHLD

EGND

24 VAC

24VAC COM

DO-1

COM

DO-2

DO-3

DO-4

DO-5

COM

DO-6

COM

1

2

3 4 5 6

7 8

1 0 9 2 3 4 5 6 7 8 0 9

1 1 1 1 1 1 1 1 1 2 1

1

2

3 4

5

6

7 8

0

9

2

2 2

2 2

2

2

2 2

3

3

1

2

3 4

5

6

7 8

0

9

3

3

3

3 3

3 3

3 4

M29340A

HOST

STATUS LED

DO-7

DO-8

COM

SBUS1

SBUS2

BACnet

STATUS LED

LOCAL BACnet MS/TP

MOLEX CONNECTOR PINS