TR21, TR22, TR23, AND TR24 WALL MODULES

3 62-0267—09

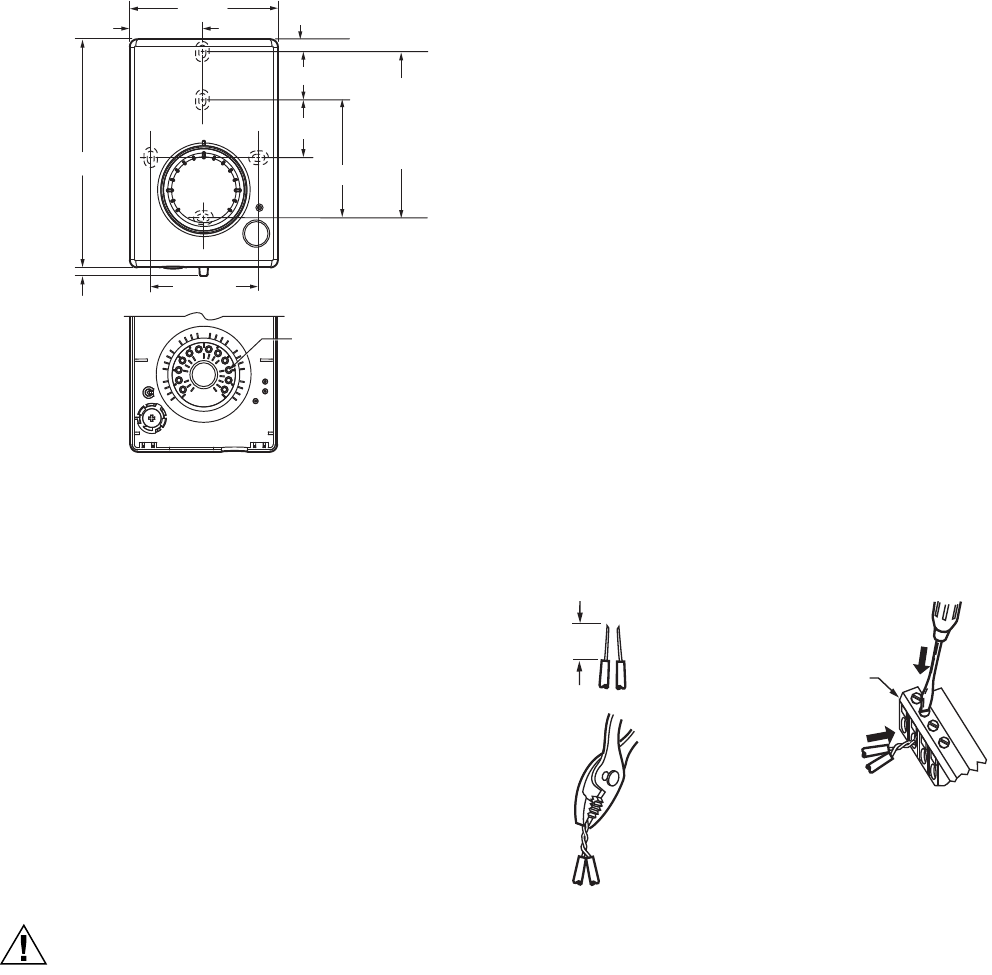

Fig. 4. Wall Module Subbase Dimensions in Inches (mm)

and Temperature Limit Set Screw Locations (TR23

Shown).

Cover Disassembly

A snap-fit locking mechanism is used to attach the cover of

the wall module to its subbase. To disassemble the cover from

the subbase:

1. Insert a thin, flat blade screwdriver into each of the two

slots at the bottom of the module to release the two

locking tabs. See Fig. 2 on page 2.

2. Tilt the cover out and away from the subbase to release

the top two locking tabs.

3. To change the dial (e.g. from Fahrenheit to Celsius)

release the two tabs on the inside of the front cover and

remove the old dial.

Wiring

Attach the wires from the device sensor terminals to the

appropriate wall module terminals. See Table 1 on page 4.

CAUTION

Improper Electrical Contact Hazard.

Screw type terminal blocks are designed to accept

no more than one 16 AWG (1.31 sq. mm)

conductor.

Connect multiple wires that are 16-18 AWG

(1.31-0.82 sq. mm) with a wire nut. Include a pigtail

with this wire group and attach the pigtail to the

individual terminal block.

Wiring Wall Modules

Wire the terminal block as follows:

1. For single wires, strip 3/16 in. (5 mm); for multiple wires

going into one terminal, strip 1/2 in. (13 mm) insulation

from the conductor.

2. If two or more wires (20 to 22 AWG only) are being

inserted into one terminal, twist the wires together

before inserting. See Fig. 5.

3. Insert the wire in the required terminal location and

tighten the screw to complete the termination.

4. Review and verify the terminal connection wiring and

DIP switch settings illustrated in Table 1 on page 4.

NOTE: Wire the Lon connection (terminals 3 and 4) using

Level IV 22 AWG (0.34 mm

2

) plenum or non-plenum

rated, unshielded, twisted pair, solid conductor wire.

Wiring Examples

Table 1 on page 4 illustrates DIP switch settings and terminal

connections for the wall modules. Refer to the TR21, TR22,

TR23, and TR24 Wall Modules – Specification Data, form

63-1321, for additional DIP Switch information.

IMPORTANT

SW 2 on DIP Switch S2 is used for factory calibration

of the temperature setpoint potentiometer.

Depending on calibration, this switch may be set in

either the On or Off position.

DO NOT change the position of this switch.

NOTES:

1. The TR21 and TR22 models do not use DIP

Switch S1 and S3.

2. DIP Switch S1 is used only on the humidity

models, TR21-H and TR23-H.

3. Models TR21 and TR21-A use terminals 1 and 2

only. Model TR21-J uses terminals 1, 2, 3, and 4

only.

Fig. 5. Attaching Two Wires (20 to 22 AWG) to Wall Module

Terminals.

Attaching the Cover

When all wiring is complete, attach the cover of the Wall

Module as follows:

1. Optional: For models with a temperature dial, insert the

two setpoint screws into the inside of the cover to set

the desired temperature range limit. See Fig. 4.

2. Press the cover straight down onto the subbase until it

snaps into place.

3. For models with a temperature dial, insert the desired

dial through the opening in the cover. Align the keyed

shaft on the knob with the keyed slot into the fitting on

the subbase, then press down until it snaps into place.

70

55

60

65

70

75

80

85

15

20

25

°F

°C

+

–

M25482

2 1/4 (57)

3/16 (5)

1 3/16 (31)

STANDARD

UTILITY

CONDUIT

BOX (2 X 4)

MOUNTING

HOLES

60

80

INSIDE OF

FRONT

COVER

TEMPERATURE LIMIT

SCREW POSITION (X12)

NOTE: IF DESIRED, INSERT THE

TWO SETPOINT SCREWS INTO

THE DESIRED POSITIONS.

2 3/8 (60)

9/16 (14)

4 13/16 (122)

3 (76)

1 1/2 (38)

7/8 (22)

1/2

(13)

STRIP 1/2 IN.

(13 MM) FROM

WIRES TO BE

ATTACHED AT

ONE TERMINAL.

1.

2.

TWIST WIRES

TOGETHER

WITH PLIERS

(A MINIMUM OF

THREE TURNS).

3.

CUT TWISTED END OF WIRES TO

3/16 IN. (5 MM) BEFORE INSERTING

INTO TERMINAL AND TIGHTENING

SCREW. THEN PULL ON EACH WIRE

IN ALL TERMINALS TO CHECK FOR

GOOD MECHANICAL CONNECTION.

M11413

CONTROLLER OR

WALL MODULE

E-BUS CONNECTOR

TERMINALS