Niles Audio Corporation

12331 S.W. 130 Street Miami, Florida 33186 Tel: (305) 238-4373 Fax: (305) 238-0185

www.nilesaudio.com

Printed in Taiwan ©1999 Niles Audio Corporation DS00131A

a hole about an inch above the center of your

proposed speaker location (See Figure 3).

If the wires movement is obstructed by a pipe or

cable, fill the hole(s) with spackle or other patch-

ing compound and try another location.

2. When determining the final location of the

cutout keep in mind that the frame and bracket

will extend beyond the cutout. Make sure that

you do not place the edge of the cutout directly

next to a stud. Locate the studs using a stud sen-

sor or hand-knocking. Once you have deter-

mined the correct position for the cutout, hold

the supplied template up to the wall surface.

Level the template in either the horizontal or the

vertical position and mark the wall with a pencil.

Drill the four corners with a 1/4” drill bit.

3. If you are cutting a painted or wall papered

wall use a sheetrock or keyhole saw. Cut the

hole with the saw at a 45 degree angle. That

way, the drywall section can be replaced cleanly

if there is an unseen obstruction behind the wall.

BE VERY CAREFUL NOT TO SAW THROUGH

EXISTING WIRES, PIPES, OR STRUCTURE. IF

YOU FEEL ANY EXTRA RESISTANCE AS YOU

ARE CUTTING, STOP.

4. If you are cutting into lath and plaster walls,

use masking tape to outline your penciled

marks, drill the four corners with a 1/4” bit and

use a razor to score the plaster down to the lath

beneath. Then use a chisel to remove all of the

plaster within the taped outline. Finally, insert a

metal cutting blade into a sabre saw and very

slowly and carefully saw the lath. Sawing the

lath can easily vibrate plaster off the wall. If you

have the patience, use a pair of tin snips to slow-

ly nip away at the lath instead. There is no risk

with this method, it is just time consuming.

5. Fill the wall cavity with insulation at this

point. Remember to use equal amounts of insu-

lation for each speaker.

6. Slip the mounting bracket through the hole

and pull it toward you so that its front edge slides

into the hole and stops in place.

7. Attach the frame to the bracket by screwing

the frame to the bracket using the supplied

screws. Do not overtighten the screws, this will

distort the frame and the grilles will not fit (this is

not permanent, just loosen the screws and the

grille will pop in). The screws should pull the

frame and bracket together (sandwiching

the drywall) so that the frame is absolute-

ly flush with the wall surface. There

should be no gaps between the wall

and the frame (See Figure 4).

Hole Cutout

Dimensions

525

6 1/4”

x 9”

650

7 5/8” x

10 5/8”

800

9 1/8” x

13 1/8”

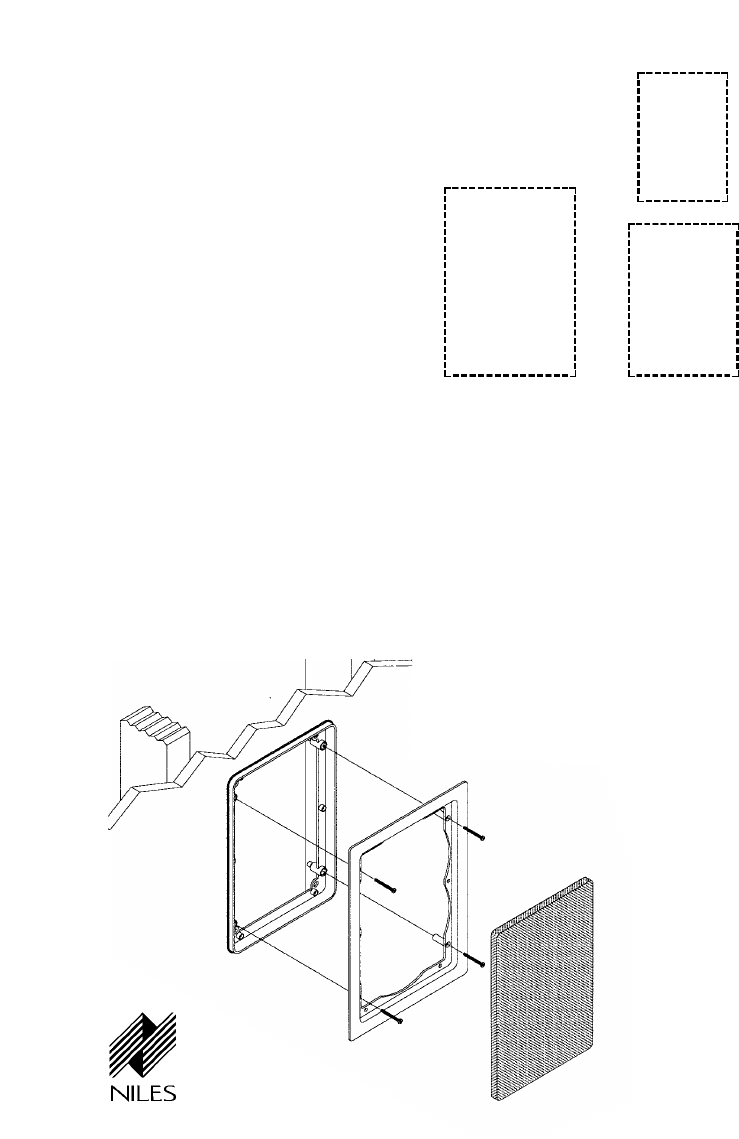

Figure 4

Figure four illustrates

the installation of an

800 bracket, frame,

and grille in existing

construction

Frame

Bracket

Grille

®