INSTALLATION

Product Specifications

Motor: Seamless can motor, 1/8 hp

Thermally protected

Lead wires: 14 GA

Fuse: See motor label for fuse size

Pump Type: Flexible impeller

Duty Cycle: Intermittent duty only

Ports:

Inlet: 1-1/2” hose barb & 1-1/2” NPT Male

Outlet: 1” hose barb

Impeller: Globe-Blue

Blade: 316 stainless “Double-cut”

Dimensions: See drawing

Weight: 5 lbs.

Approvals: UL ignition protected, ISO 8846

CSA, CE styles available

Typical Flow: Dependent on fluid viscosity

Chart below based on water

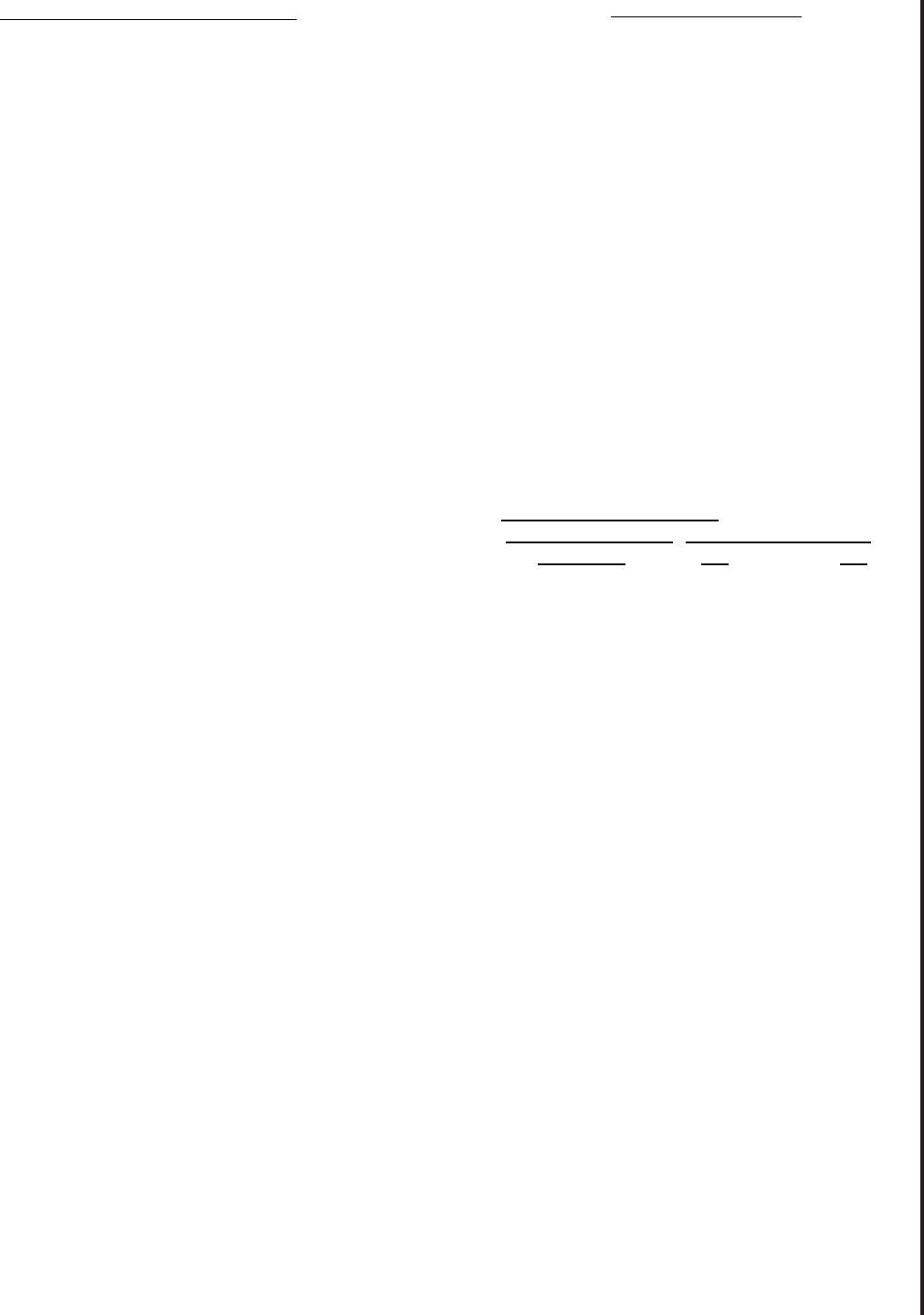

Head Flow gpm[lpm] Max DC Amps

Ft [m] 12 V 24V 12V 24V

0 [0] 13 [49] 13 [49] 17 8

12 Volt System

Min. Wire Size (20 Amps)

Total Wire Length * 3% Drop 10% Drop

feet [m] GA GA

1-10 [.3-3] #10 #16

11-20 [3.3-6] #8 #14

21-30 [6.4-9.1] #6 #12

30-60 [9.1-18.2] #4 #10

*length from power source to motor

and back to ground.

Maximum Operating Head = 30 feet

Electrical Installation Checklist

√ Separate circuit from power source

√ Proper size momentary switch mounted

near pump

√ Proper wire size to length

√ Proper fuse size and type

√ Insulated wire connectors

WARNING:

Pump should be operated on a separate circuit.

Pump should be connected to properly sized

momentary switch. This prevents pump from

damage due to dry run condition.

Switch should be near pump. This will allow

operator to hear change in pump sound when tank

is empty.

NOTE: For proper operation motor must

rotate counterclockwise when viewed from

pump end.

Plumbing Connections

Pump should be mounted as near as possible to tank

to minimize dry run. Pump is self-priming to a

five-foot lift when impeller is wet, four foot lift

when impeller is dry. Pump is more efficient if

mounted near the holding tank.

INLET: Always install pump with a shut-off

valve between pump and holding tank.

Hose: Use 1-1/2” ID [non-collapsible

vacuum rated] hose on inlet [suction]

side. Use stainless steel hose clamps

on all sanitation connections.

Flange: To mount to 1-1/2” female flange, inlet

barb must be cut off just before threads.

Seal threads and hand tighten.

Warning: Any air leak on inlet side can cause

pump to run dry and can damage

impeller and impeller housing.

Check all inlet side connections, even

those on deck plates. All runs should

be smooth with no kinks or sharp

angles.

OUTLET: Use 1” minimum ID hose on discharge

side of pump. Connect to thru-hull

fitting above highest heeled point

above waterline. Vented loop

installations must vent at least 10”

above highest heeled point above

waterline. Use stainless steel hose

clamps on all sanitation connections.