PRELIMINARY

WMK 100 Installation Notes, cont'd

2

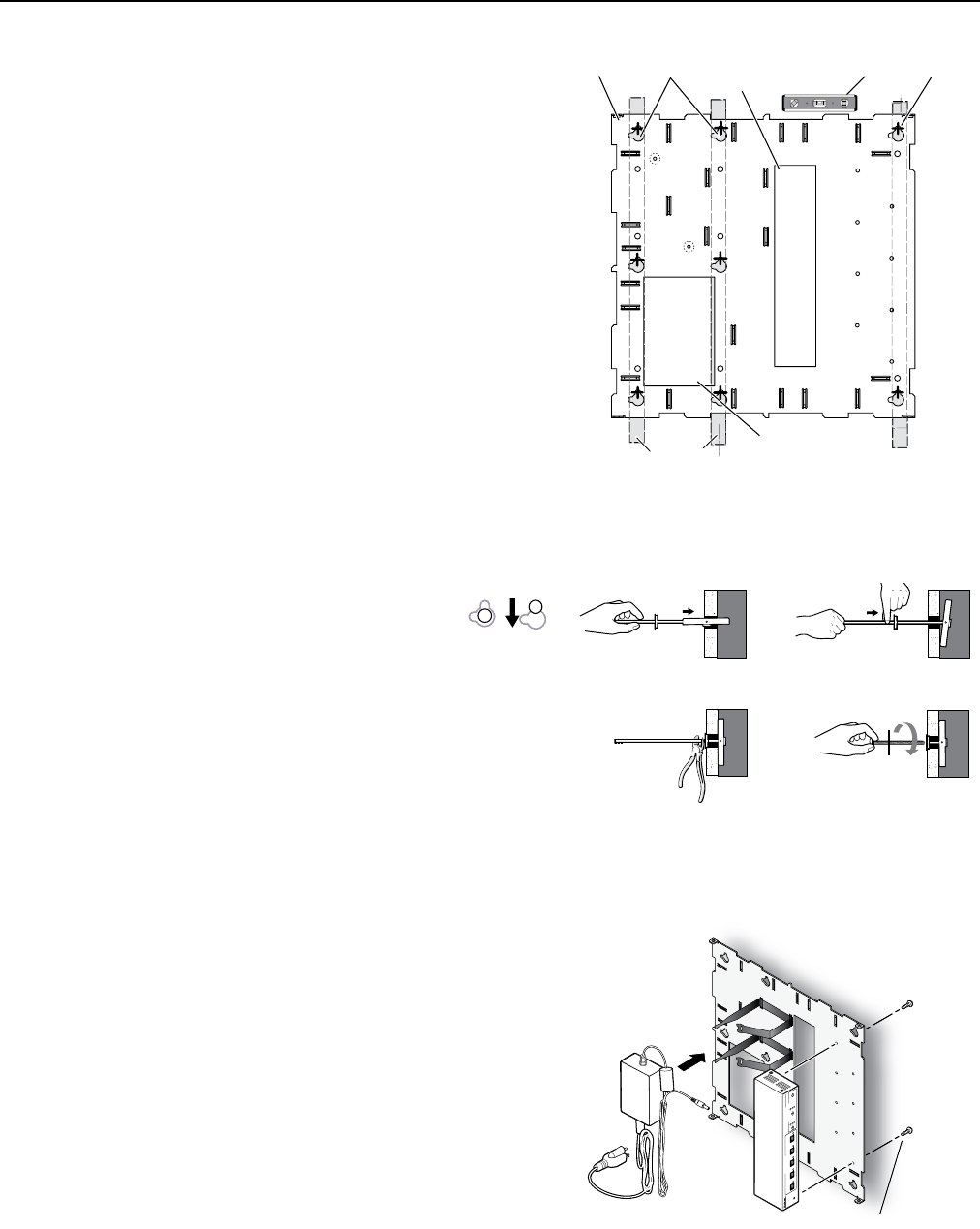

1B. To mount the WMK 100 onto a non-masonry wall:

i. At the desired site locate the wall studs and mark their

locations.

N

For ideal installation secure the base plate to at least one

wall stud (see figure 3). Drywall Kap toggles can be used

for holes not aligned with studs.

The base plate can be installed over an existing electrical

outlet. The opening fits standard sized 2.75" x 4.5" wall

plates. See inset on figure 2.

ii. Hold and level the base plate against the wall and mark

the positions of the slotted mounting holes that are on

the stud lines (see figure 3, indicated by + marks). Where

applicable, mark the mounting holes on the wall for

drywall toggles. Set the plate aside.

iii. Drill 1.75" (4.4 cm) deep pilot holes at the marked

locations.

iv. Insert the self tapping screws into the pilot holes, until a

gap of 1/8" to 3/8" (3 to 9 mm) remains between the wall

and the screw heads.

N

If using toggle assemblies see figure 4 for installation

method.

v. Align the base plate's slotted mounting holes

over the installed screws, then slide the plate

down so the screws fit into the slots.

vi. At this time, lightly tighten all the screws to ensure plate

fits flush to the wall and verify level and position.

N

Do not over tighten, as the plate needs to be removed to

attach the switcher and power supply before cabling.

vii. If the cables are to be run behind the wall to the WMK

location, mark the cutout area on the wall for the signal

cable access hole (see figure 3).

viii. Remove the base plate and cut out the marked area.

2. Mount the switcher and power supply

a. Remove the WMK 100 base plate from the wall, and with the

switcher's rear ports facing the cable access hole, align

the two corner holes in the base of the switcher with the two

outermost device mounting holes in the WMK 100 base plate.

Secure with the supplied 440 x ¼" screws.

b. Attach the power supply above the electrical outlet cutout,

with the supplied hook-and-loop straps. Attach it so the cables

are easily and safely routed to the electrical outlet and switcher

alike.

c. Re-attach the plate to the wall and secure firmly.

Figure 3 — Non-masonry wall mounting

Wall Studs

Cutout for

Electrical

Outlet

Level

Cutout for

Signal Cable

Access

Marker for

Pilot Hole

WMK 100

Base Plate

Mounting

Holes

+

+

(2) 4-40 x 1/4" screws

(2) 4

-

40x1/4

"

sc

rew

s

PVS 305SA

POLEVAULT SWITCHER

INPUT SELECTION

1

2

PEAK

NORMAL

SIGNAL

CONFIG

3 4

5

AUX AUDIO

AUDIO LEVEL ADJUST

PAGING

SENSOR

SENSITIVITY

VOICELIFT

MIC

PEAK

NORMAL

SIGNAL

INPUT

Figure 4 — Toggle assembly installation

a. Grasp handle, collapse

toggle and insert into wall.

b. Slide plastic washer

down into pilot hole.

c. Cut off handle close to wall.

d. Hand screw in pan head

bolt until 1/8" gap remains.

Figure 5 — Attach switcher and power

supply to base plate