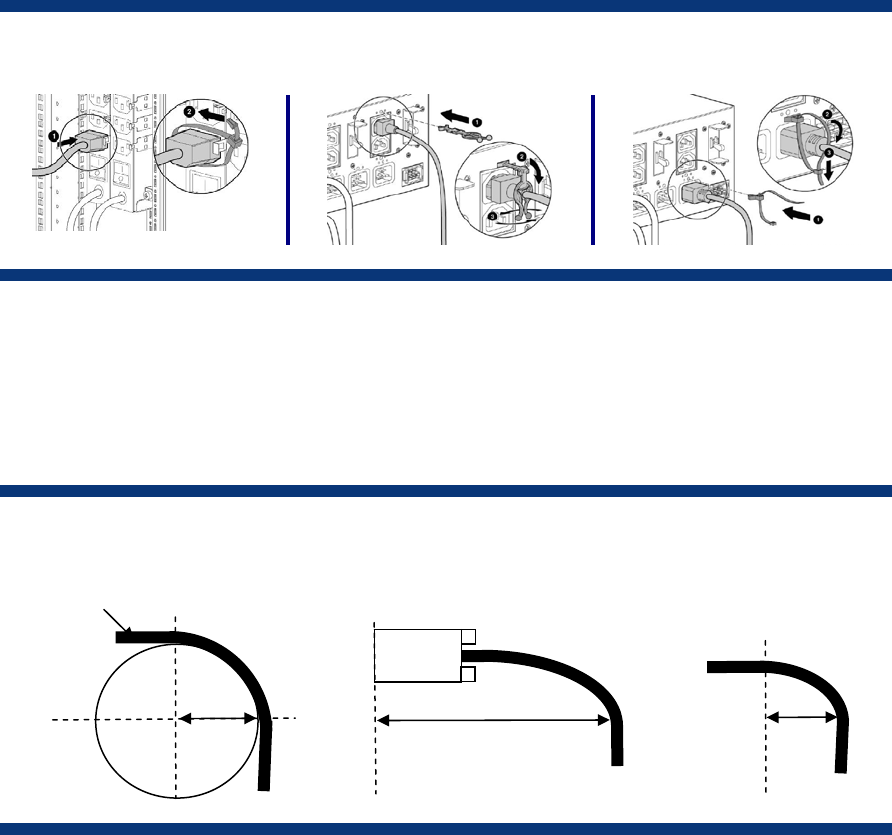

Securing power cables and connectors

Power cables and connectors should receive extra care during installation, since loose cables or

connectors can result in loss of power and unscheduled downtime. A loose power connector can

create high contact resistance that can result in arcing and a fire hazard. HP power distribution

products are often supplied with cable retaining clips or clamps (Figure 2), and HP strongly advises

using these accessories when they are provided.

For securing power cables and connectors, HP recommends the following:

• Always use any provided hardware (such as retaining clips or tie strips) to secure power connectors

and cords to the product chassis.

• When possible, secure PDU power cables with removable ties to

prevent accidental removal of the

cords from the system.

Figure 2. Example of retaining, clamp system securing power cords on HP products

Cable bend-radius restrictions

Routing cables typically requires looping excess cable or bending cable around chassis components.

The bend radius is defined as the minimum radius (Figure 3) to which a cable may safely be bent

without damaging the cable or affecting its performance.

Figure 3. Cable bend radius

Radius (R)

0°

90°

Cable

R1

(

bend radius at connector

)

R1

R2 (bend radius away

from connector

)

R2

To avoid the consequences of a too short or too tight bend radius, HP recommends the following

practices:

• Avoid tight bend radii. Never bend cables tight enough to cause a crease in the sheathing.

• With no exceptions, fiber cables must not violate their minimum bend radius.

• Avoid excessive bends in cable, and run as large a bend as space allows.

4