SPYDER® BACNET® PROGRAMMABLE CONTROLLERS

63-2689—05 6

Panel Mounting

The controller enclosure is constructed of a plastic base plate

and a plastic factory-snap-on cover.

NOTE: The controller is designed so that the cover does

not need to be removed from the base plate for

either mounting or wiring.

The controller mounts using four screws inserted through the

corners of the base plate. Fasten securely with four No. 6 or

No. 8 machine or sheet metal screws.

The controller can be mounted in any orientation. Ventilation

openings are designed into the cover to allow proper heat

dissipation, regardless of the mounting orientation.

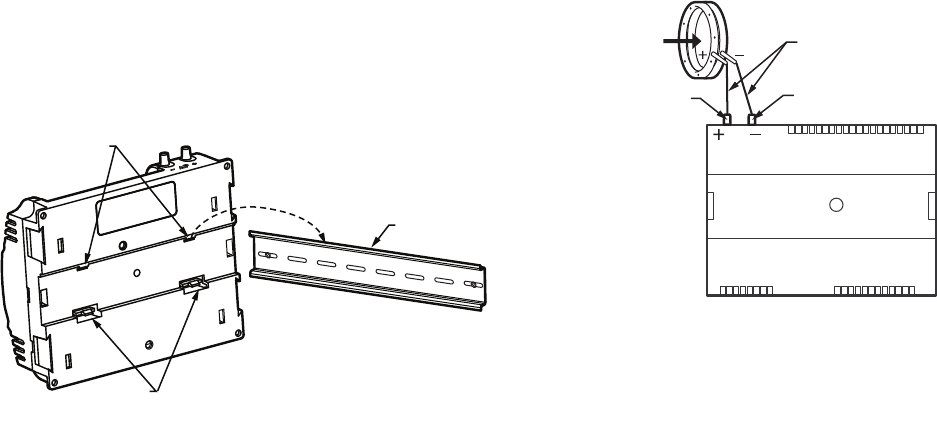

DIN Rail Mounting (PUB1012S, PUB4024S,

PUB6438S, PVB4024NS and PVB6438NS)

To mount the PUB1012S, PUB4024S, PUB6438S,

PVB4024NS and PVB6438NS controllers on a DIN rail

[standard EN50022; 1-3/8 in. x 9/32 in. (7.5 mm x 35 mm)],

refer to Fig. 8 and perform the following steps:

1. Holding the controller with its top tilted in towards the DIN

rail, hook the two top tabs on the back of the controller

onto the top of the DIN rail.

2. Push down and in to snap the two bottom flex connectors

of the controller onto the DIN rail.

IMPORTANT

To remove the controller from the DIN rail, perform the

following:

1. Push straight up from the bottom to release the top

tabs.

2. Rotate the top of the controller out towards you and

pull the controller down and away from the DIN rail to

release the bottom flex connectors.

Fig. 8. Controller DIN rail mounting (models PUB1012S,

PUB4024S, PUB6438S, PVB4024NS and PVB6438NS).

Piping (PVB0000AS, PVB4022AS,

PVB4024NS, PVB6436AS and

PVB6438NS)

Air flow Pickup

For PVB0000AS, PVB4022AS, PVB4024NS, PVB6436AS and

PVB6438NS, connect the air flow pickup to the two restrictor

ports on the controller (see Fig. 9).

NOTES:

— Use 1/4 inch (6 mm) outside diameter, with a 0.040

in. (1 mm) wall thickness, plenum-rated 1219 FR

(94V-2) tubing.

— Always use a fresh cut on the end of the tubing

that connects to the air flow pickups and the

restrictor ports on the controller.

Connect the high pressure or upstream tube to the plastic

restrictor port labeled (

+), and the low pressure or downstream

tube to the restrictor port labeled (

-). See labeling in Fig. 9.

When twin tubing is used from the pickup, split the pickup

tubing a short length to accommodate the connections.

NOTES:

— If controllers are mounted in unusually dusty or dirty

environments, an inline, 5-micron disposable air

filter (

use 5-micron filters compatible with

pneumatic controls)

is recommended for the high

pressure line (marked as

+

) connected to the air

flow pickup.

— The tubing from the air flow pickup to the controller

should not exceed three feet (0.914 m). Any length

greater than this will degrade the flow sensing

accuracy.

— Use caution when removing tubing from a connec-

tor. Always pull straight away from the connector or

use diagonal cutters to cut the edge of the tubing

attached to the connector. Never remove by pulling

at an angle.

Fig. 9. Air flow pickup connections (PVB0000AS,

PVB4022AS, PVB4024NS, PVB6436AS and PVB6438NS).

Power

Before wiring the controller, determine the input and output

device requirements for each controller used in the system.

Select input and output devices compatible with the controller

and the application. Consider the operating range, wiring

requirements, and the environment conditions when selecting

input/output devices. When selecting actuators for modulating

applications consider using floating control. In direct digital

control applications, floating actuators will generally provide

control action equal to or better than an analog input actuator

for lower cost.

Determine the location of controllers, sensors, actuators and

other input/output devices and create wiring diagrams. Refer to

Fig. 17–Fig. 23 beginning on page 14 for illustrations of typical

controller wiring for various configurations.

DIN RAIL

TOP TABS

BOTTOM FLEX

CONNECTORS

M16815

M23556A

AIR FLOW

PICKUP

ΔP

1

2

3 4 5 6

7 8

1 0 9 2 3 4 5 6 7 8 0 9

1 1 1 1 1 1 1 1 1 2 1

1

2

3 4

5

6

7 8

0

9

2

2 2

2 2

2

2

2 2

3

3

1

2

3 4

5

6

7 8

0

9

3

3

3

3 3

3 3

3 4

RESTRICTOR

PORT

RESTRICTOR

PORT

CONNECTOR

TUBING