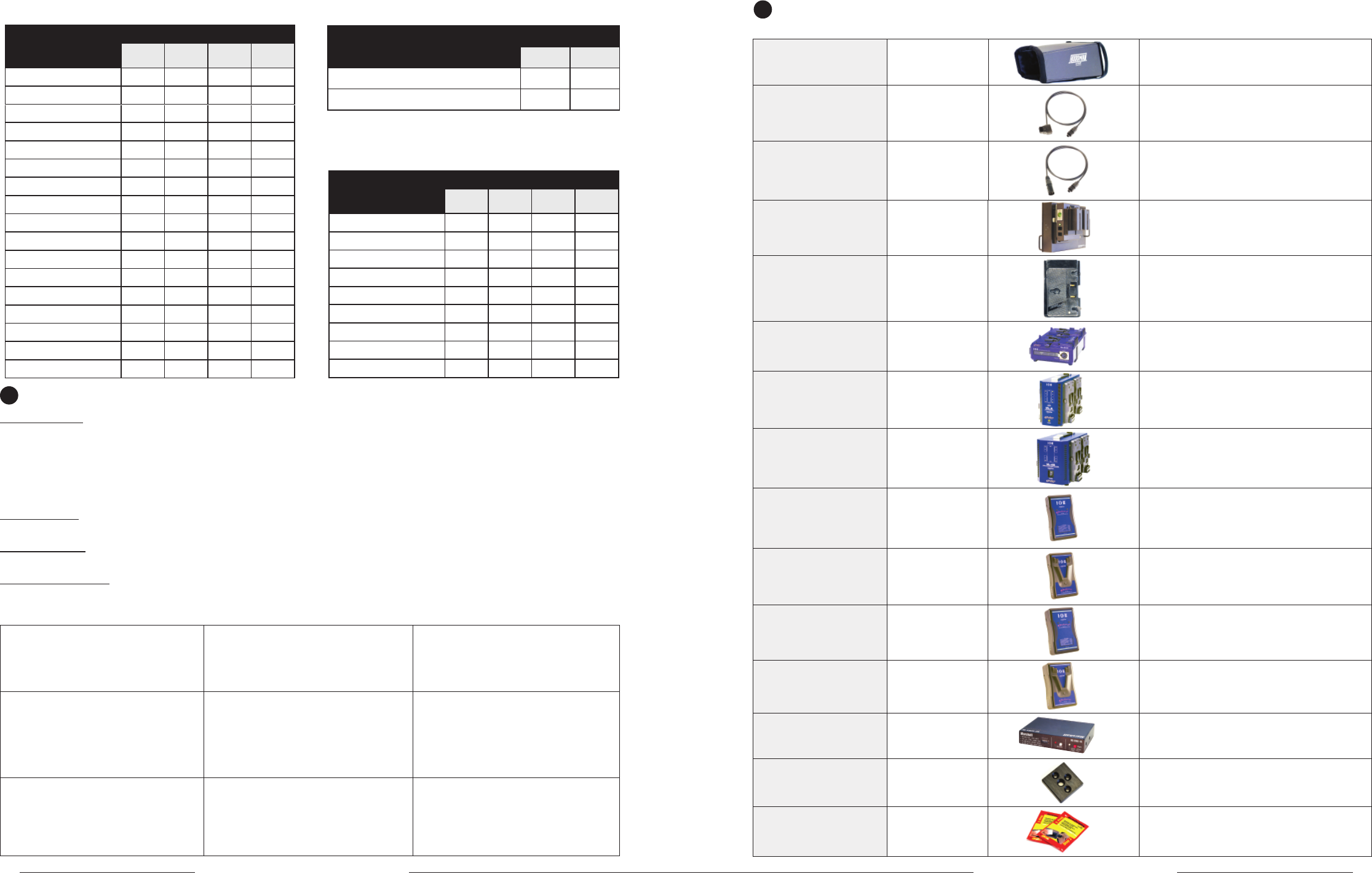

Battery Adapter

V-DV-PWR1

Uses 2 Sony DVCam/HDV FP-Type batteries.

When used with monitor power supply, can

charge batteries plus operate monitor

V-mount to Anton Bauer

adapter

V-ABA-01

Use to power Marshall Electronics monitors

that have V-Mount plate with Anton Bauer Gold

Mount battery.

Sequential 2 channel

charger

IDX-VL-2Plus

2-channel sequential charger with a built-in 60W

power supply. Charges 2 ENDURA E series bat-

teries in fewer than 5 hours. One 10’ XLR cable

included. Weighs only 2 lbs

Sequential 4 channel

charger

IDX-VL-4

Economically charges 4 ENDURA E series bat-

teries in under 6 hours using Full Power Charge

(FPC) method

Simultaneous 4 channel

charger

IDX-VL-4S

Charges 4 ENDURA E series batteries in 2.5

hours or less

55 W Lithium Battery IDX-E7S V-Mount battery pack with 3 LED power Indicator

55 W Lithium Battery

with Power Link

IDX-E7

V-Mount Battery Pack with PowerLink includes

accurate Power Status Display and supports

Digi-View

82 W Lithium Battery IDX-E10S V-Mount battery pack with 3 LED power Indicator

82 W Lithium Battery

with Power Link

IDX-E10

V-Mount Battery Pack with PowerLink includes

accurate Power Status Display and supports

Digi-View

Digital to Analog

Converter

BC-0301-10 Converts SDI to analog Composite

Mounting Plate VP-LCD70-TMB-02

Attaches to any side for mount to ¼-20 threaded

component

Cleaning Wipes V-HWP-K

Package of 10 non-toxic, antistatic, alcohol and

ammonia free cleaning wipes.

Table 3 / Video Signals Displayed via SDI

Input Signal Type and aspect

SDI

4:3 16:9

NTSC (720x486i 60Hz) Y Y

PAL (720 x 576i 50Hz) Y Y

5

4

Input Signal Type

and aspect

DVI-D VGA

4x3 16x9 4x3 16x9

640 x 480 60Hz YYYY

640 x 480 75Hz YYYY

640 x 480 85Hz YYYY

800 x 600 60Hz YYYY

800 x 600 75Hz YYYY

800 x 600 85Hz YYYY

1024 x 768 60Hz Y Y Y Y

1024 x 768 75Hz YYYY

1024 x 768 85Hz YYYY

Table 1 / Computer Signals Displayed via DVI and VGA connector

Input Signal Type

and aspect

Y Pr Pb DVI

4x3 16x9 4x3 16x9

720 x 486 60i Y Y x x

720 x 576 50i Y Y x x

1280 x 720 60P Y Y Y Y

1280 x 720 50P Y Y Y Y

1280 x 720 30P Y Y x x

1280 x720 29.97P Y Y x x

1280 x720 25P Y Y x x

1280 x 720 24P Y Y x x

1280 x 720 23.98P Y Y x x

1920 x 1080 60i Y Y Y Y

1920x1080 59.94i Y Y Y Y

1920 x 1080 50i Y Y Y Y

1920 x 1080 30P Y Y Y Y

1920x1080 29.97P Y Y Y Y

1920 x 1080 25P Y Y Y Y

1920 x 1080 24P Y Y Y Y

1920 x 1080 24Psf Y Y Y Y

Table 2 / Video Signals Displayed via DVI and YPrPb connections

(x=not available) (HDMI requires adapter to DVI)

V-R84DP-SD Users Guide

Marshall Electronics

Sun Hood V-H900 Use for viewing in bright lighting or outdoors

Power Adapter Cable V-PAC-D Use with Anton Bauer D-type connection

Power Adapter Cable V-PAC-XLR Use with 4 Pin XLR connections

9

Optional Accessories

8

Faceplate Cleaning

Faceplate Cleaning

When cleaning the faceplate it is very important to use non-abrasive and ammonia free cleaning agents and a clean micro fi ber cloth. Do not use paper

towels. Paper towel fi bers are coarse and may scratch the surface of the Polycarbonate faceplate. Paper towels may also leave streaks on the surface.

Antistatic and fi ngerprint resistant cleaning agents are recommended.

Wash protective cover with a solution of mild soap or detergent and lukewarm water. Use a clean soft cloth, applying only light pressure. Rinse with clean

water and dry by blotting with a damp cloth or chamois. Grease, oil or tar may be removed with a good grade of hexane, aliphatic naphtha, or kerosene.

These solvents may be obtained at a paint or hardware store and should be used in accordance with manufacturer’s recommendations.

DO NOT USE: window cleaning sprays, kitchen scouring compounds or solvents such as acetone, gasoline, benzene, alcohol, carbon tetrachloride, or

lacquer thinner. These can scratch the sheet’s surface and/or weaken the sheet causing small surface cracks called “crazing.”

Faceplate Dusting

Dust with a soft, damp cloth or chamois. Dry or gritty cloths may cause surface scratches and create a static electric charge on the surface. Neutralizing

static electricity effects by using recommended cleaning and polishing practice.

Faceplate Polishing

Protect and maintain surface gloss by occasional polishing with a good plastic cleaner and polish. Apply a thin, even coat with a soft clean cloth and pol-

ish lightly with cotton fl annel. Then wipe with a damp cloth to help eliminate electrostatic charges that can attract dust particles

Marking on the Faceplate

Use SHARPEE or equivalent marker. Clean as per instructions with an ammonia free cleaning agent.

210 Plastic Cleaner & Polish and 210 Plus Cleaner

Sumner Laboratories

186 Lincoln Street

Boston, MA 02111

617-542-8656 / Fax: 617-482-9001

Exair Corporation

1250 Century Circle North

Cincinnati, OH 45246-3309

513-671-3322

Fax : 513-671-3363

www.exair.com

Plexus Plastic Cleaner

Plexus

638 Lindero Canyon Rd. #371

Agoura, CA 91301

800-405-6495

Fax: 818-879-0697

Crystalclean

Discovery Plastics

3700 Western Way, NE

Millersburg, OR 97231

541-926-2900 / Fax: 541-967-8441

www.discoveryplastics.com

The Simco Industrial Static Control

An Illinois Tool Works Co.

2257 North Penn Road

Hatfi eld, PA 19440-1998

800-203-3419

215-822-2171

Fax: 215-822-3795

www.simco.biz

NOVUS #1 Plastic Clean and Shine

NOVUS, Inc.

12800 Highway 13 South, Suite 500

Savage, MN 55378

800-548-6872 ext.451

Fax: 952-946-0435

Scotch-Brite High Performance Cloth

3M Stationery & Offi ce Supplies Div.

3M Center

St. Paul, MN 55144-1000

877-362-5684

Fax: 651-733-0382

www.mmm.com

20/20 Plastic-Cleaner

Craftics, Inc.

PO Box 91930

Albuquerque, NM 87199

(505) 338-0005

Recommended Anti-Static Cleaners and Polishes