The operational modes are:

1. AUTOMATIC SENSING

2. UTP/STP —> RO or STATION

3. UTP/STP —> RI or LOBE

The power / error LED turns red when an attachment error occurs. An error

can only occur when attaching to active devices (devices which signal for

insertion with phantom current or the fiber optic key). The error condition

occurs when copper device initiates the phantom current and the fiber optic

device initiates the fiber optic key. In Token Ring, the active insertion pro-

cess may only be directed from one direction.

SELF TEST / MEDIA TEST MODE

FIBER READY

(top left)

MEANING

COPPER

READY (top

right)

MEANING

GREEN

Data received from

fiber

GREEN

Data received from

copper

OFF

No data is being

received from fiber

OFF

No data is being

received from coppe

r

POWER /

ERROR (bot.

left)

MEANING

INSERT

STATUS (bot.

right)

MEANING

YELLOW Power is on YELLOW

The OmniHawk™ is

in the self test /

media test mode.

DIAGNOSTIC FEATURES

The OmniHawk™ diagnostic features make it easy to install and maintain.

There are four levels of diagnostics: Power-On LED Test, Self Test / Media

Test, Installation Test, and run-time ready and error monitoring.

4

APPLICATIONS

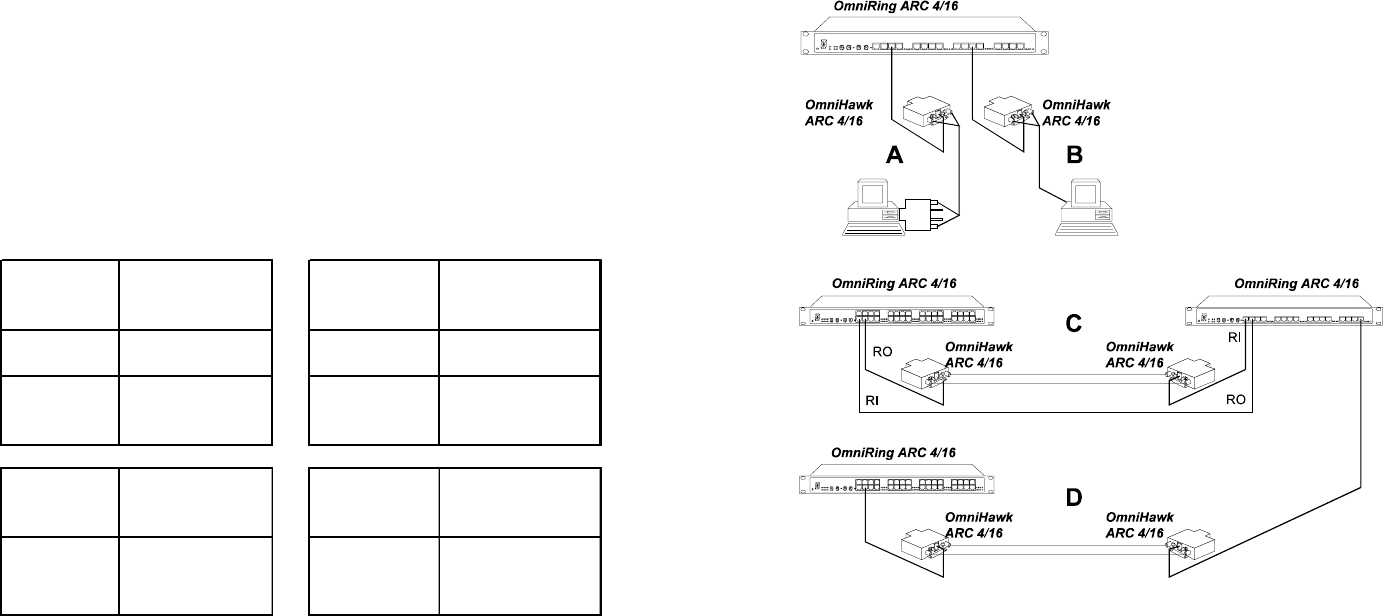

The following drawing illustrates three different applications of the

OmniHawk™.

A. STP Workstation (DB9) to distant hub (RJ45)

Application A shows an STP workstation connecting via its DB9 connector

directly to one OmniHawk™, which is connected to a second OmniHawk™

via fiber optic cables. The last connection to the hub is made via a standard

CAT-5 patch cable.

B. Fiber optic Workstation to hub (RJ45)

Application B shows a fiber optic workstation connecting to an OmniHawk™

vi its fiber optic cables. The OmniHawk™ connects to the hub via a stan-

dard CAT-5 patch cable.

9