R2XL1 • 10

RAMSEY “LEARN-AS-YOU-BUILD” ASSEMBLY STRATEGY

Be sure to read through all of the steps and check the boxes as you go along

to be sure you don't miss any. Although you may be in a hurry to see results,

before you switch on the power check all wiring and capacitors for proper

orientation. Also check the board for any possible solder shorts and/or cold

solder joints. All of these mistakes could have detrimental effects on your kit,

not to mention your ego!

Kit building tips:

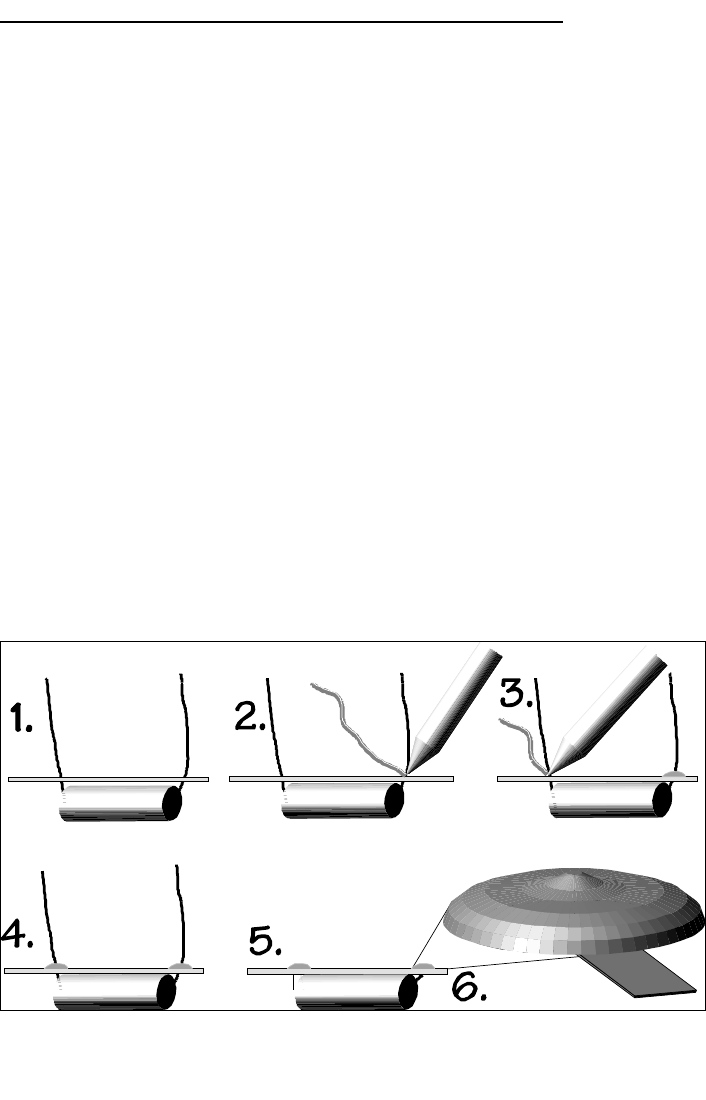

Use a good soldering technique. Let your soldering iron tip gently heat the

traces to which you are soldering making sure to heat both the leads and the

pads simultaneously. Apply the solder to the the pad when the junction is hot

enough to melt the solder. The finished joint should look like a drop of water on

paper, somewhat soaked in.

Mount all electrical parts on the top side of the board provided. The top side is

clearly marked with a white silkscreen showing the part numbers, you can’t

miss it. This is the side that has little or no traces on it, but is covered with

mostly copper. When parts are installed, the part is placed flat to the board, and

the leads are bent on the backside of the board to prevent the part from falling

out before soldering (1). The part is then soldered securely to the board (2-4),

and the remaining lead length is then clipped off (5). Notice how the solder joint

looks on close up, clean and smooth with no holes or sharp points (6).