3

INSTALLATION

NOTE

All wiring should be installed according to local and national

electrical codes and ordinances.

The 47D43-811 control may be mounted on any convenient

surface using the six standoffs provided.

The control must be secured to an area that will experience

a minimum of vibration and remain below the maximum

ambient temperature rating of 150

o

F. The control is approved

for minimum ambient temperatures of -40

o

F.

Any orientation is acceptable.

Refer to the wiring diagram and wiring table when connecting

the 47D43-811 control to other components of the system.

UL approved, 105

o

C rated 18 gauge min., stranded 2/64”

thick insulation wire is recommended for all low voltage safety

circuit connections.

UL approved, 105

o

C rated 16 gauge min., stranded 2/64”

thick insulation wire is recommended for all line voltage

connections.

Following installation or replacement, follow appliance

manufacturer’s recommended installation or service

instructions to insure proper operation.

On some units, the Outdoor Ambient Temperature (OAT) and

Outdoor Coil Temperature (OCT) sensors may be attached

permanently to the controller. The 47D43-811 includes

replacement OAT and OCT sensors that plug onto the 2- and

3-pin connectors on the controller board.

Before removing the old controller, note the location of the

OCT sensor on the outdoor coil. The new sensor should

be attached to the coil in the same location, or as close as

possible. The OAT sensor is typically 24-48” long, although

some controllers have the sensor on the board. Placement of

the OAT sensor is not as critical as the OCT sensor, but both

sensors are required for the controller to operate.

Six metal standoffs, 0.375 inch long, are used to support and

mount the control into the unit.

Board size is 3.375 in. x 3.625 in. and requires 1 inch of

headroom (not including mounting).

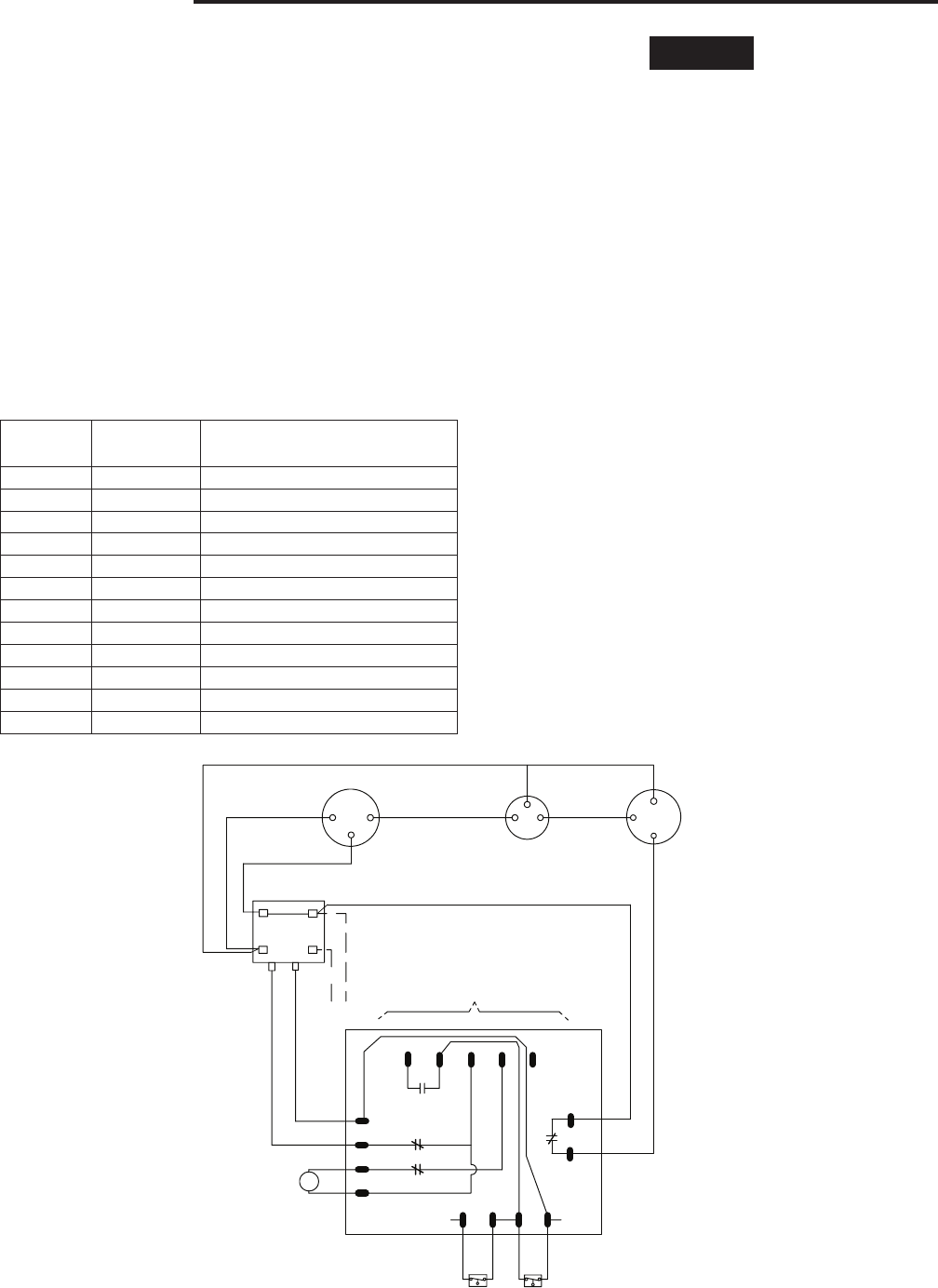

Typical System Wiring Table

47D43

Terminal Type System Component Connection

C 0.25” QC Reversing valve common

RV 0.25” QC Reversing valve output

HPC (2) 0.25” QC High pressure cutout switch

LPC (2) 0.18” QC Compressor call output

CC 0.25” QC Compressor contactor coil

Fan (2) 0.25” QC Outdoor fan control

C 0.25” QC Common, 24 VAC return

R 0.25” QC 24 VAC input

D 0.25” QC Defrost output

Y 0.25” QC Compressor call input

OAT 2-pin connector Outdoor ambient temperature sensor

OCT 2-pin connector Outdoor coil temperature sensor

Fig 1. Typical System Wiring Diagram

LPC

HPC

REVERSING

VALVE

FAN

Yout

RV

FAN

C

RV

CC

D

K2

K2

Y

C

B

R

K1

COMPRESSOR

CONTACTOR

TO THERMOSTAT

RUN CAPACITOR

COMPRESSOR

OUTDOOR

FAN MOTOR

HERM FAN

L1

L2

C

LOW

PRESSURE

CUT-OUT

HIGH

PRESSURE

CUT-OUT

R

S

C

S

R

C

CC

K3

To µP

To µP