7

6

Inside RV

For roof thickness greater than 6-1/2”.

Parts Needed: (not included)

14” worm gear for roof

Directional handle extension

Long threaded rod

Instructions:

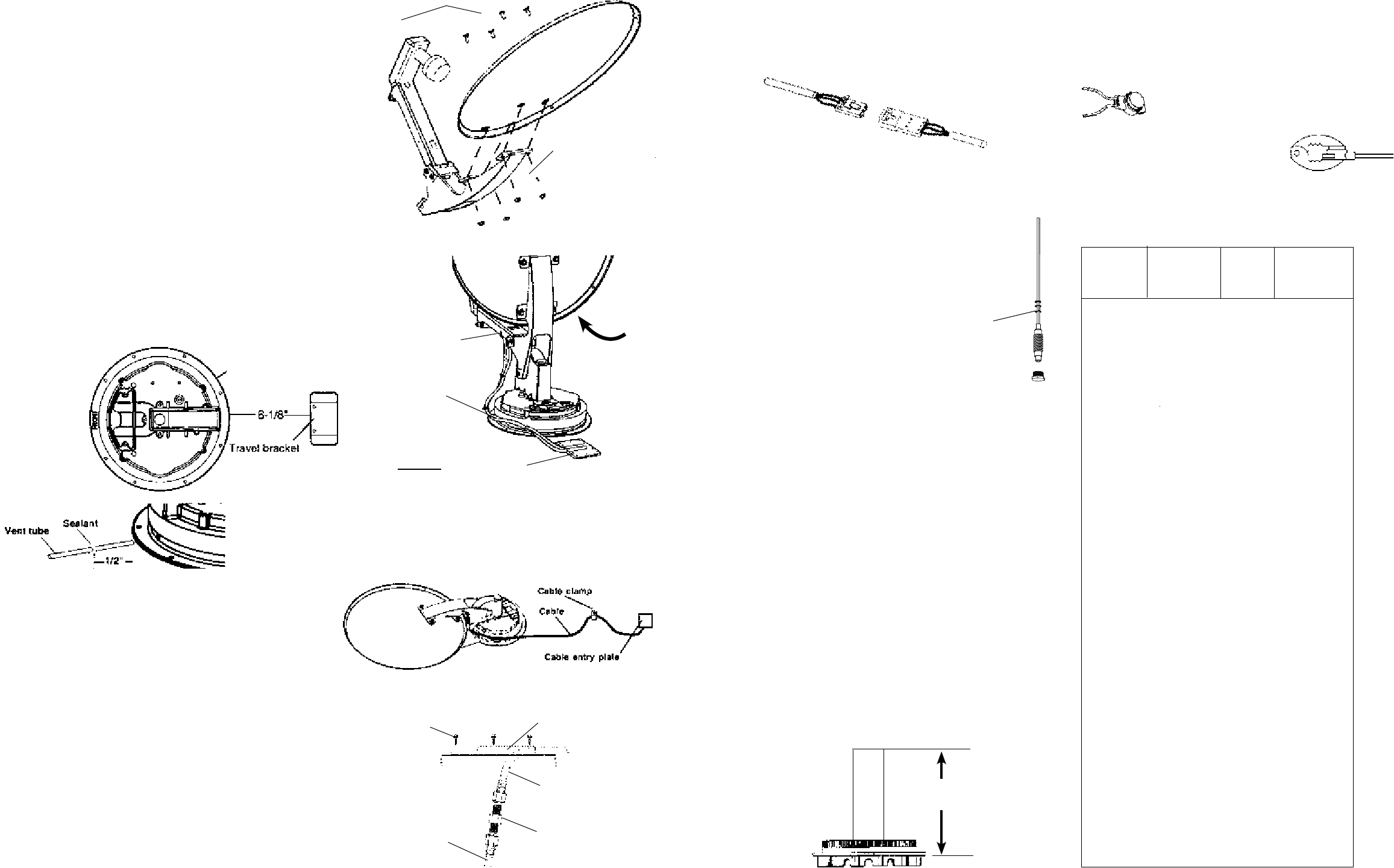

STEP 8. Place nut on threaded rod. See Figure 8.

STEP 9. Measure and cut the threaded rod with a

hacksaw. Use the chart (Figure 10) to determine the

correct length.

Digital Elevation Sensor Roof Connections

The illustrations below show the different methods of connecting wires at roof level; method will depend on model.

Wire colors must match, i.e. red to red, green to green, black to black.

This wire harness connects to the digital

elevation sensor on the antenna.

NOTE: This terminal is NOT WEATHERPROOF

and CANNOT be left outside on the roof.

Snap

connectors

together

Supplied with DM-2000 only

3M UR TERMINAL

NOTE: This terminal is weatherproof

and can be left outside on the roof IF

SECURED PROPERLY to prevent wind

whipping.

DO NOT STRIP

wires. Terminal

is self-stripping.

Slide wires all the way in.

Squeeze pliers until

red plunger is flush

with rest of terminal.

(Pliers not supplied.)

STEP 10. Remove the nut over the cut end of the

threaded rod. This cleans the threads after cutting.

STEP 11. Thread the cut end of the rod into the hub.

STEP 12. Install the ceiling plate. The rotate/lock lever

must point toward the rear of the vehicle.

Be sure rotate/lock lever is pointing towards the rear

of the vehicle and that the hole in ceiling plate aligns

with hole in the ceiling.

Refer to the chart to determine the correct length for

the directional handle. Extensions may be needed. Each

extension adds 2-1/4” to directional handle. DO NOT cut

the extension. If the directional handle must be extended

by less than 2-1/4”, cut the directional handle to fit.

A tube cutter is recommended for cutting the

directional handle. This gives a square cut; a hacksaw

does not.

Be sure large and small keyways line up in the hub and

directional handle!

Figure 9

DIRECTIONAL

HANDLE

1-1/2” ................2-7/8” ................. 2-3/4” ................. 2-7/8”

1-3/4” ................3-1/4” ................. 3” ....................... 3-1/8”

2” ...................... 3-1/2” ................. 3-1/4” ................. 3-1/2”

2-1/4” ................3-7/8 ................... 3-1/2” ................. 3-7/8”

2-1/2” ................4-1/8” ................. 3-3/4” ................. 4-1/8”

2-3/4” ................4-1/2” ................. 4” ....................... 4-1/2”

3” ...................... 4-3/4” ................. 4-1/4” ................. 4-3/4”

3-1/4” ................5” ........................ 4-5/8” ................. 4-7/8”

3-1/2” ................5-1/4” ................. 4-7/8” ................. 5-1/8”

3-3/4” ................5-5/8” ................. 5-1/4” ................. 5-1/2”

4” ...................... 5-3/4” ................. 5-1/2” ................. 5-3/4”

4-1/4” ................6-1/8” ................. 5-3/4” ................. 6-1/8”

4-1/2” ................6-1/2” ................. 6” ....................... 6-1/4”

4-3/4” ................6-5/8” ................. 6-1/8” ................. 6-3/8”

5” ...................... 6-7/8” ................. 6-3/8” ................. 6-5/8”

5-1/4” ................7-1/8” ................. 6-5/8” ................. 7”

5-1/2” ................7-3/8” ................. 6-7/8” ................. 7-1/4”

5-3/4” ................7-5/8” ................. 7-1/4” ................. 7-1/2”

6” ...................... 7-7/8” ................. 7-1/2” ................. 7-3/4”

6-1/4” ................8-1/8” ................. 7” ....................... 8”

6-1/2” ................8-1/2” ................. 7-3/4” ................. 8-1/4”

6 3/4” ................ 8 3/4”.................. 8” ................... 8 1/2”

7” .................. 9” .................... 8 1/4” ................. 8 7/8”

7-1/4” ................9-3/8” ................. 8 5/8” ................. 9 1/8

7-1/2” ................9-5/8” ................. 8 7/8” ................. 9 3/8

7-3/4” ................9-7/8” ................. 9 1/8” ................. 9 5/8

8” .................. 10-1/8” ............... 9 3/8” ................. 10

8-1/4” ................10-3/8” ............... 9 5/8” ................. 10 1/4

8-1/2” ................10-3/4” ............... 9 7/8” ................. 10 3/8

8-3/4” ................11” .................. 10” ................. 10 5/8

9” .................. 11-1/4” ............... 10-1/4” ............... 11

9-1/4” ................ 11-1/2” ............... 10-5/8” ............... 11 1/4

9-1/2” ................ 11-3/4” ............... 10 7/8” ............... 11 1/2

9-3/4” ................ 12” ................. 11 1/8” ............... 11 3/4

10” ................ 12-3/8” ............... 11 3/8” ............... 12

10-1/4” .............. 12-5/8” ............... 11 5/8” ............... 12 1/4

10-1/2” .............. 12-7/8” ............... 11 7/8” ............... 12 1/2

Figure 10

Measure 24” of coax

at plastic fastener on

left side of feed arm.

(See Step 5.)

No cable clamps on

this part of cable.

Rotate

clockwise

to stop.

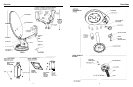

STEP 3. Attach dish to backup. Use bolts and nuts

provided. See Figure 4.

STEP 4. Mount dish on roof in upright position. Rotate

clockwise to stop (Figure 5). Dish will be toward back

of vehicle when in stowed or travel position. The word

FRONT is embossed on the base and should face the

front of vehicle. Secure to roof using screws (provided).

The travel bracket should be mounted to roof 6-1/8”

from base of dish, toward back of vehicle. See Figure 6.

NOTE: Apply non-hardening sealing compound to

screw heads, coax access hole and edge of gasket

under mount base.

Install the vent tube on the back of the mount base (the

side opposite the word FRONT). The hole for the vent

tube is shown in Figure 6A. CAUTION: DO NOT seal

hole in vent tube. Put sealant around the outside of the

vent tube, approximately 1/2” from end. Push vent tube

into the hole. The sealant will seal the hole as you push

in vent tube. Leave approximately 2 to 2-1/2” of the vent

tube extending from the hole. Put a small amount of

sealant on the roof under the vent tube end to hold in

place.

Figure 4

Figure 5

(4) Antenna

Mounting Bolts

(4) 1/4-20

Hex Nuts

Figure 6A

Install cable entry plate 3”

minimum from mount base.

CAUTION: DO NOT GET sealing compound between

base plate and rotating gear housing. DO NOT PAINT

top of base plate or around rotating gear housing.

STEP 5. Facing the front of the dish, note the coax

attached to the side of the feed arm. Measure 24” coax

from this point. DO NOT CUT. Put coax around mount

base, Figure 5.

STEP 6. Apply approved sealing compound over

mounting screw heads in base plate.

STEP 7. Feed coax through the roof using cable entry

plate (included). See Figure 7. Weatherproof the cable

entry by applying sealant under lip of cable entry

plate and where cable enters roof. Attach plate to roof

with screws provided. Apply sealant over screws and

around edge of roof-thru plate, making sure cable entry

is sealed. If downlead connection is made on top of

roof, make sure to weatherproof connection!

Figure 7

Cable Entry Plate

CE-2000

#10 x 1” Screws

Down lead

connects to

satellite receiver

FS-8100

Male-to-male

F-connector

Down lead

Another Method of Installing Roof/Cable Entry Plate

Attach cable to roof using cable clamps. Use sealant to

seal screw heads.

Figure 6

Base Plate

HANDLE

LENGTH

Roof

Thickness

Directional

Handle Length

(Figure 9)

Worm Gear

Shaft Length

(Figure 11)

Threaded

Rod

Length

Threaded Rod,

Washer and Nut

Figure 8