© Emerson Power Transmission Manufacturing, L. P. or affiliates 2002. All Rights Reserved.

CENTERASSEMBLY

HUB BOLTS

O.D. PILOT

ADAPTER RING

COLLAPSING BOLT

DISC PACK

SPACER

Disconnect all power before adjusting units

3.0 Alignment

Note: Exact values and procedures for aligning equipment are normally

specified by the equipment manufacturers. Good initial alignment to

the minimum possible values will promote optimum machinery per-

formance and eliminate potential operating problems. After securely

tightening the foundation bolts, the hub separation and alignment

should be rechecked and adjusted if necessary.

The coupling alignment should be checked periodically. Even

when a coupling is well aligned at installation, subsequent settling of

foundations, shifting of equipment, etc., may cause the alignment to

deteriorate.

Offset and Angular Alignment

3.1 Reverse dial indication or optical methods of alignment (such as la-

ser) are recommended. A cold alignment and a hot check (with cor-

rections if necessary) are required. The hub flange OD can be used to

mount the alignment equipment. The hub flange OD is machined to

be concentric to the coupling bore and can be used as the reference

diameter.

3.2 The maximum recommended operating misalignment is:

0.10 degrees per disc pack

(0.0035 in/in TIR equivalent parallel offset)

Important: Total misalignment is the combination of equipment par-

allel offset

and angular misalignment.

Note that improving the alignment below these values will promote

optimum machinery performance.

Axial Alignment

3.3 Align the hubs until they are at the correct hub separation. The hub

separation is measured from the two flange faces, not from the pilot

face.

Hub Separation = Center Assembly Length

4.0 Final Assembly

(KD2 and KD20)

4.1 After correctly installing both hubs, use the separate collapsing screws

to pull the adapter rings toward the center of the pre-assembled cen-

ter section. This is made up of the spacer, two disc packs, and two

adapter rings.

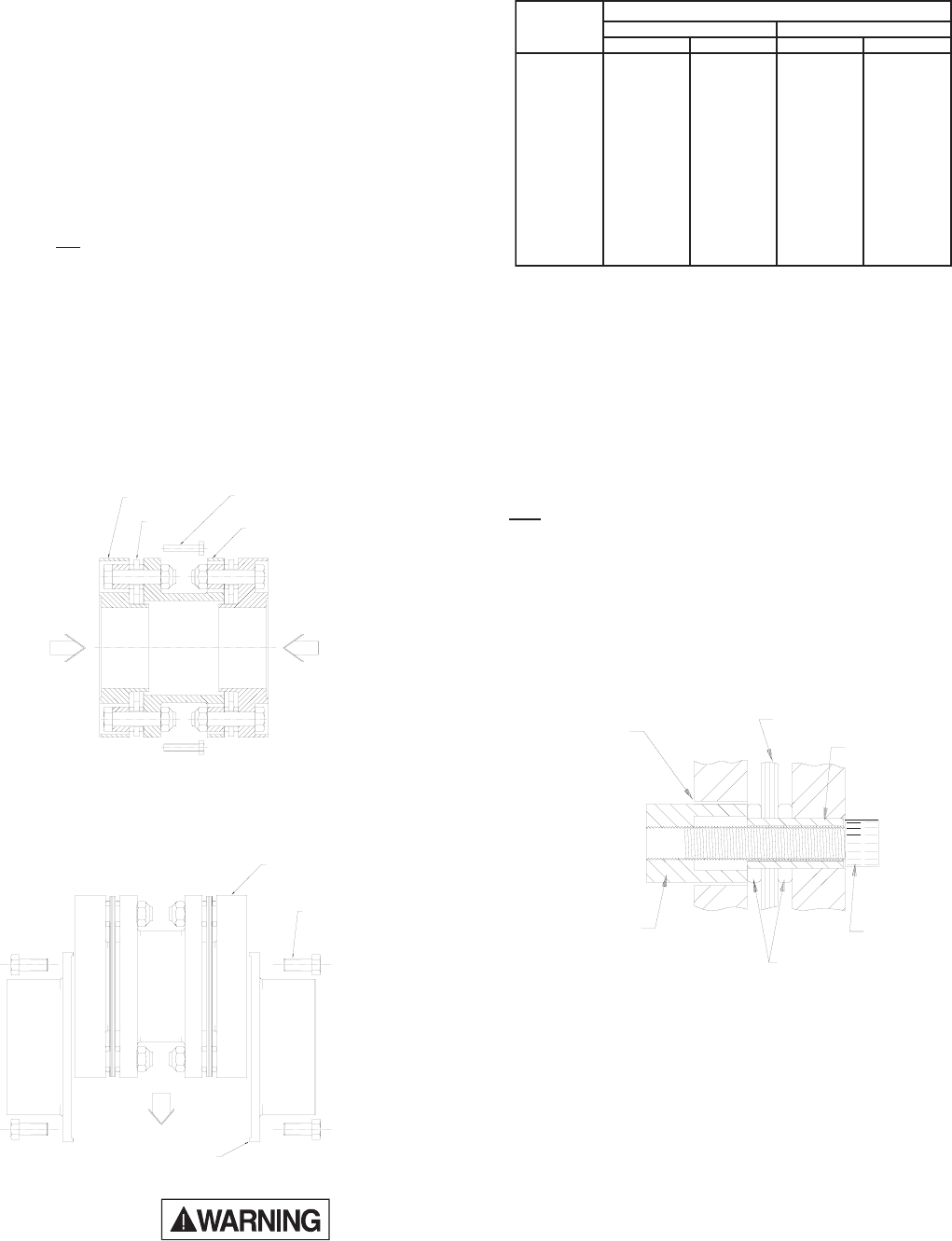

Figure 5. Installing center section.

Table 1. Flange Bolt Tightening Torques.

Figure 4. Collapsing center section

Figure 6. Bolt Disc Pack to Adapter.

4.4 Put the center assembly (spacer and rings) between the rigid hubs,

engage the pilot, and install the hub bolts in one hub flange.

4.5 Release all the collapsing bolts, and install the hub flange bolts on the

second rigid hub flange.

4.6 Torque the hub flange bolts to the value specified in Table 1.

4.2 For each side of the center section, insert the collapsing bolts through

the spacer clearance holes into tapped holes in the ring (see Figure 4).

4.3 Tighten them evenly and collapse the disc packs equally, only enough

to allow the center assembly to drop intoplace (see Figure 5).

5.0 Removal

5.1 Disassemble the coupling in the reverse order as per the applicable

assembly procedure.

5.2 KEYED HUBS - Install a puller on the hub using the tapped holes

provided in the hub face. Pull the hub off the shaft.

6.0 Disc Pack Replacement

The terminology used to identify parts and the order of assembly may differ

from one coupling style to another. Follow the instructions which match the

coupling style being installed.

KD2 - For KD20 skip to 6.7

6.1 Remove the center assembly in reverse order as per the applicable

assembly procedure. Remove disc pack bolts and nuts.

6.2 Insert the disc pack removal socket into one of the clearance holes in

the spacer flange or ring (Figure 6). Install the removal cap screw and

turn it until it cannot be tightened any more.

Note: The removal socket is supplied as part of the “parts kit”.

6.3 Remove the tool and repeat step 6.2 on all bushings to free the disc

pack from the ring and spacer.

gnilpuoC

eziS

)deliOylthgiL(euqroTgninethgiT

2DK02DK

bl-tfm-Nbl-tfm-N

301801----

351801----

402,30203040507

452,35203040507

403,30357001011051

453,35357001051002

404,304051002072073

454,354051002072073

405----034085

455----046078

406----046078

507----02110051

508----07410002

509----07410002

CLEARANCE HOLE

DISC PACK

BUSHING

REMOVALSOCKET

WASHER

REMOVALSCREW

The Emerson logo is a trademark and a service mark of Emerson Electric Co.