© Emerson Power Transmission Manufacturing, L. P. or affiliates 2002. All Rights Reserved.

Important Safety Instructions

Before start-up . . . for reasons of safety and to extend shaft coupling life,

follow these requirements.

1. Coupling guards protect personnel.

ALL COUPLINGS MUST BE COVERED WITH A GUARD AS PER OSHA REQUIREMENTS.

2. Recheck alignment after all foundation bolts and mechanical connections are tightened.

3. Make sure all fasteners are properly installed and tightened.

4. Take the time to double check your work.

5. Only authorized KOP-FLEX replacement parts are to be used.

6. Call KOP-FLEX for any clarification or questions.

5 YEAR WARRANTY REGISTRATION CARD

Name (Last, First)

Title:

Company Name:

Location:

Phone:

APPLICATION DATA

Coupling Type:

HP:

RPM:

Application:

Shaft Size(s): Driving: Driven:

Distance Between Shaft Ends

Plant Identification Pump # Motor #

Send Warranty Card To: Attention Marketing Department

KOP-FLEX, Inc.

Mail to: P. O. Box 1696 or Fax to: 410-787-8424

Baltimore, MD 21203-1696

9.0 Bore Sizing and Recommended Fit

The finish bore size should be based on the actual measured shaft dimen-

sion, regardless of whether straight or taper shaft. For keyed shafts, a light

interference fit based on a nominal interference rate of 0.0005 inch per inch

of shaft diameter is suggested, or refer to published AGMA standards. Do

not exceed an interference fit of 0.001 inch/inch of shaft diameter. If other

than a light interference fit is desired, consult the published AGMA boring

and keyway standards.

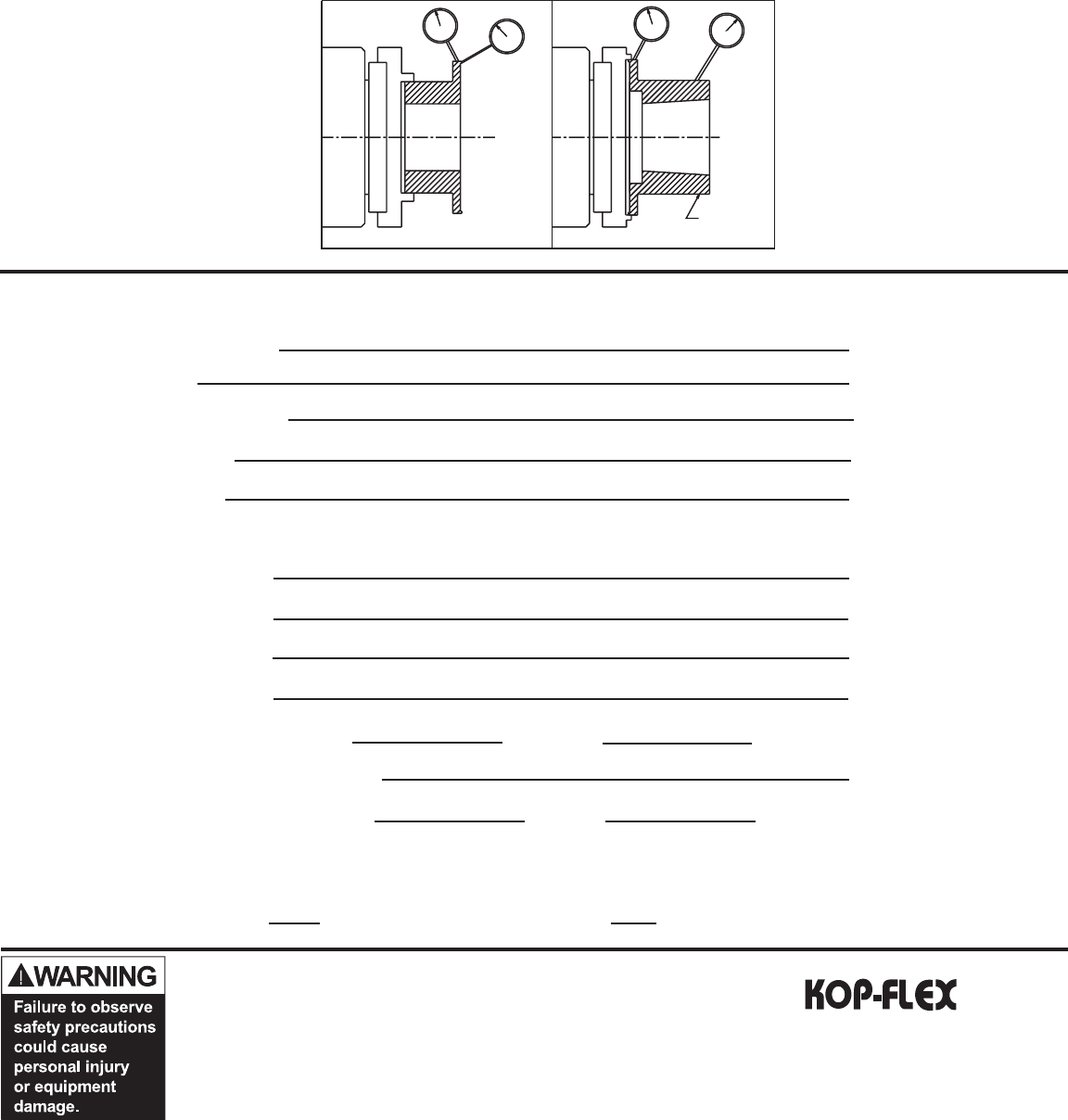

For Straight Bores, the rigid hub diameter should be chucked in the bor-

ing lathe and dial indicated as shown of Figure 11. For Taper Bores, chuck

and indicate as shown on Figure 11. Machine the counterbore and SKIM A

REFERENCE DIAMETER on the hub body. Then chuck the hub as shown

on Figure 12, and indicate using the reference diameter before final boring.

Run-outs should be as near zero as possible. It is essential that the fin-

ished bore be concentric with the two indicating surfaces.

10.0 Keyways

Keyways should be cut to give a tight fit on the sides and slight clearance

over the key. Keyways should not have sharp corners. Refer to published

AGMA standards for specific dimensioning of coupling bores and keyways.

11.0 General Recommendations

11.1 KOP-FLEX KD2 and KD20 disc couplings are designed to operate for

extended periods without the need for lubrication or maintenance. Visual

inspection of the disc packs is sufficient to assess the operational condition

of the coupling.

11.2 All machinery should be monitored to detect unusual or changing vi-

bration levels. KOP-FLEX KD2 and KD20 couplings, under normal condi-

tions, have no wearing parts and will retain their original balance quality.

Any change in vibration levels should be investigated and remedial action

should be taken immediately.

Figure 11

Figure 12

REFERENCE

DIAMETER

Emerson Power Transmission

P. O. Box 1696

Baltimore, MD 21203-1696

www.emerson-ept.com

®