16

Multimeter with Temperature

4

Disassembly and Reassembly

Referring to Figure 1, disassemble the Meter as follows. A

Phillips-head screwdriver and small flat-blade screwdriver

are required.

1. Remove the test leads and set the rotary knob to OFF.

2. Remove the Phillips-head screws from the case bottom.

3. Separate the case top from the case bottom.

4. To replace the battery: lift the battery from the case

bottom and insert a new 9V battery. Be sure the positive

and negative battery posts are oriented correctly.

5. To remove the pca: insert a small, flat-blade

screwdriver between the edge of the case top and the

pca where shown in Figure 2. Gently unsnap a side of

the case top from the pca. Repeat on the other side of

the pca. Unsnap the case from the top of the pca last.

Lift the pca from the case top by its edges. If the

elastomeric contact strips for the switch assembly and

LCD are stuck to the pca, remove them without touching

the conductive edges.

Note

Before reinserting the pca, make sure that the

rotary knob is in the OFF position.

7. To reinsert the pca: Place the pca over the four screw

posts in the case top, then press gently on the center of

the pca while using the small flat-edge screwdriver to

shoehorn the pca under the snap on a side of the case

top. Repeat on the other side and the top.

8. To remove the switch support, use a small, flat-blade

screwdriver to gently unsnap the sides and top of the

switch support from the snaps shown in Figure 2.

9. The LCD, switch assembly, and elastomeric contact

strips for the LCD and switch assembly are accessible

and can be replaced as needed. Do not allow the LCD

to get wet. Before installing a new LCD, make sure that

all connector contact points are clean.

Caution

Do not touch the conductive edges of the

elastomeric strips or the contacts on the switch

assembly. If they are contaminated, clean them

with isopropyl alcohol.

9. Reassembling the Meter is the reverse of disassembling

it. After the Meter is reassembled, execute the

Performance Test to confirm that the Meter is working

properly.

Cleaning

W Warning

To avoid electrical shock, remove test leads

and any input signals before cleaning.

To clean the case, wipe it with a cloth lightly dampened with

water and a mild detergent. Do not use abrasives, solvents,

or alcohol.

Recommended Test Equipment

A list of recommended equipment for the performance test

and calibration adjustment procedure is shown in Table 2.

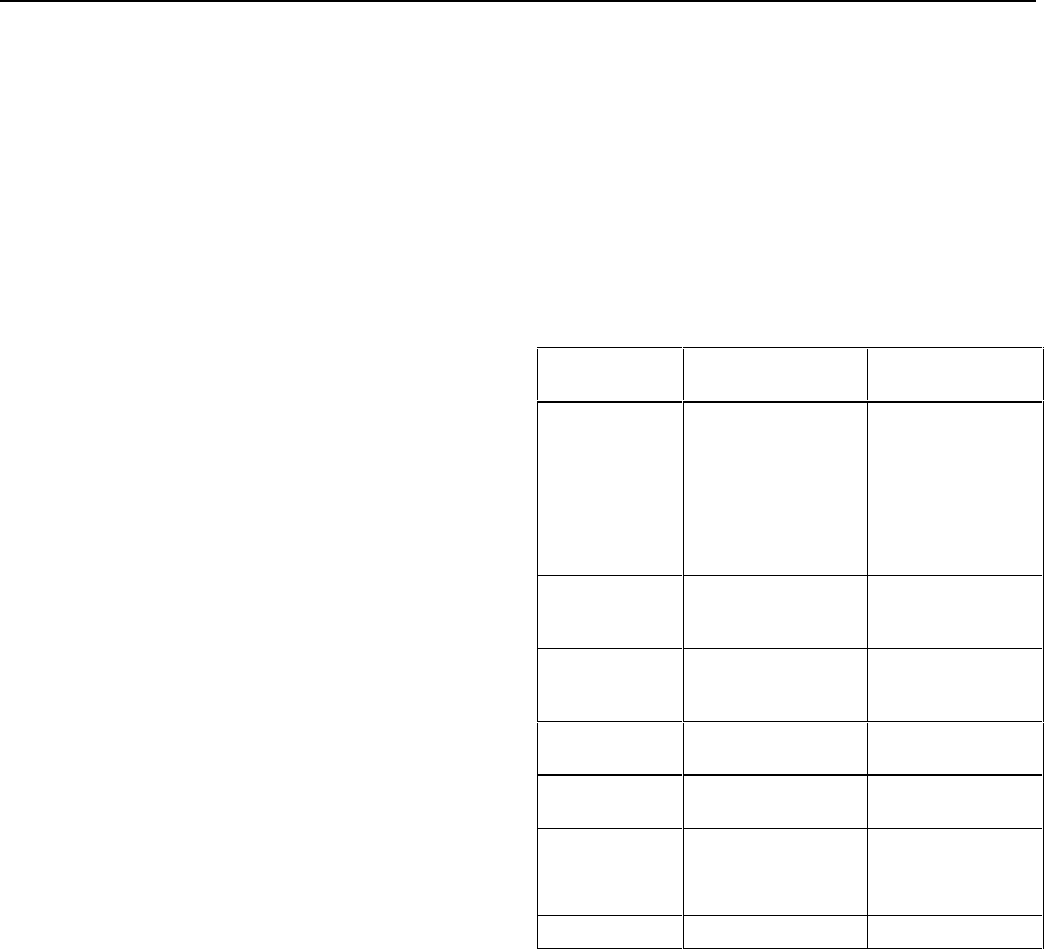

Table 2. Recommended Equipment

Equipment Minimum

Specification

Recommended

Model

AC/DC Calibrator DC Voltage: 0 to

600 V

Accuracy: ±0.25%

AC Voltage: 0 to

600 V

Accuracy: ±0.5%

Frequency: 50 to

400 Hz

5700A, or 5500A

Decade Resistor Resistance: 1.0 to

40 MΩ

Accuracy: ±0.25%

Fluke 5500A

Decade

Capacitor

Capacitance: 0 to

1.000 µF

Accuracy: ±0.5%

Fluke 5500A

Thermocouple

Wire K-Type

--- Fluke 80 PK-1

Temperature

Probe

Accuracy: Certified

to ±0.2°C ambient

Fluke 80T-150U

Mercury

Thermometer

0.02°C resolution

0.05°F resolution

Princo Model ASTM

56C

Princo Model ASTM

56F

Flask with cap --- Dewar Flask