Installation

14 313259D

Installation

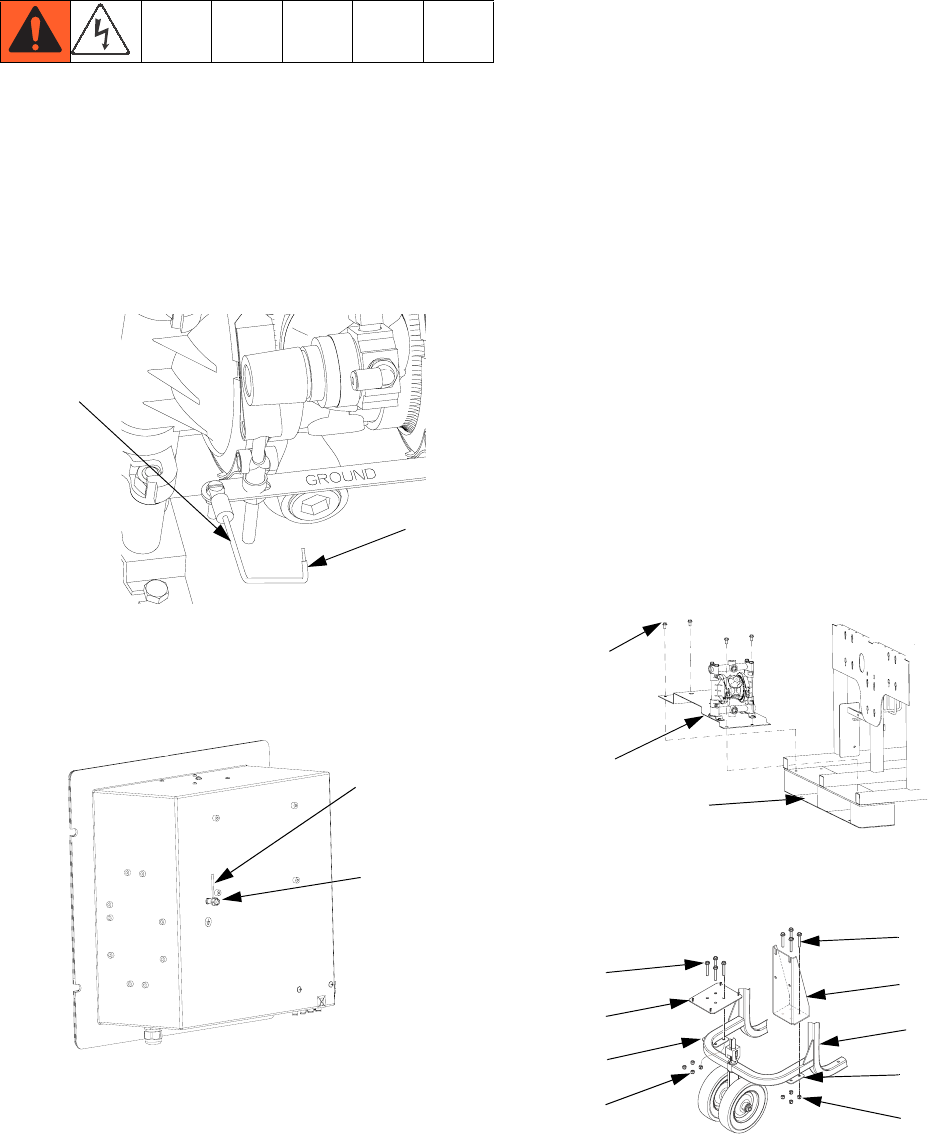

Grounding

The equipment must be grounded. Grounding reduces

the risk of static and electric shock by providing an

escape wire for the electrical current due to static build

up or in the event of a short circuit.

1. Remove grounding screw on diaphragm pump (3)

and tighten ring terminal on grounding cable (15)

under ground screw.

2. Loosen grounding lug locknut (W) on back of control

box. Insert ground wire end (Y) into lug slot and

tighten locknut securely.

Tubing Lengths

The length of tubing (4, 16, 29) is determined by the

hopper mounting configuration and heating choices.

Reference the fluid schematic, from the configurations

listed below, to find the tubing lengths.

• Heating hoppers only. See F

IG. 2 on page 9.

• Heating hoses only. See F

IG. 6 on page 13.

• Heating hoppers and hoses. See F

IG. 4 on page 11.

Cut tubing to length specified in fluid schematics.

1. Use tubing cutter to cut tubing (4) squarely to

desired lengths.

NOTE: To ensure a leak-proof seal, apply PTFE tape

on all npt threads.

2. Insert tubing through the back of the nut in each of

the plastic fittings (7) until the tube stops. Tighten

the nut hand tight, then tighten it to 1-1/2 to 2 turns

with a wrench.

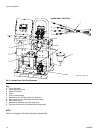

Install

1. XM Kit 256273 only: Mount bracket (1) on XM

frame (D) using screws (5).

2. XP Kit 24M224 only: Mount brackets (101, 102) on

XP frame (D) using plates (105), screws (134),

nuts (133).

15

Y

r_256273_313259_9

Y

W

r_256273_313259_10

5

1

D

r_256273_313259_5

102

101

D

105

134

133

133

134

105

ti19176a