1.

Certificado de Garantia

7.

Maintenance

Cleaning

Calibration

Calibration for Low Conductivity Reading(Ultra Pure Water)

8

All OMEGA equipments, are shipped from factory tested and calibrated. When under operation, the

Conductivity Cell must be maintained periodically (the frequency will depend on the process), which

would be basically cleaning, or if necessary, a new calibration.

Dip the electrodes in cleaning solution for 40 seconds, then wash throughly with deionized

water to avoid standard contamination, when it is time to perform a calibration.

Equipments with range of 0 to 200µS or higher.

1. Dip cell 3 or 4 times in standard compatible with the equipment range. Wait 1 minute before you

can adjust the A.T.C. (Automatic Temperature Compensation), If necessary, move it vertically (up

and down) in order to eliminate any bubbles.

2. Proceed with the constant adjustment.

3. Repeat the operation "1" two or three times in order to confirm the value.

Range 0.01µS thru 2µS

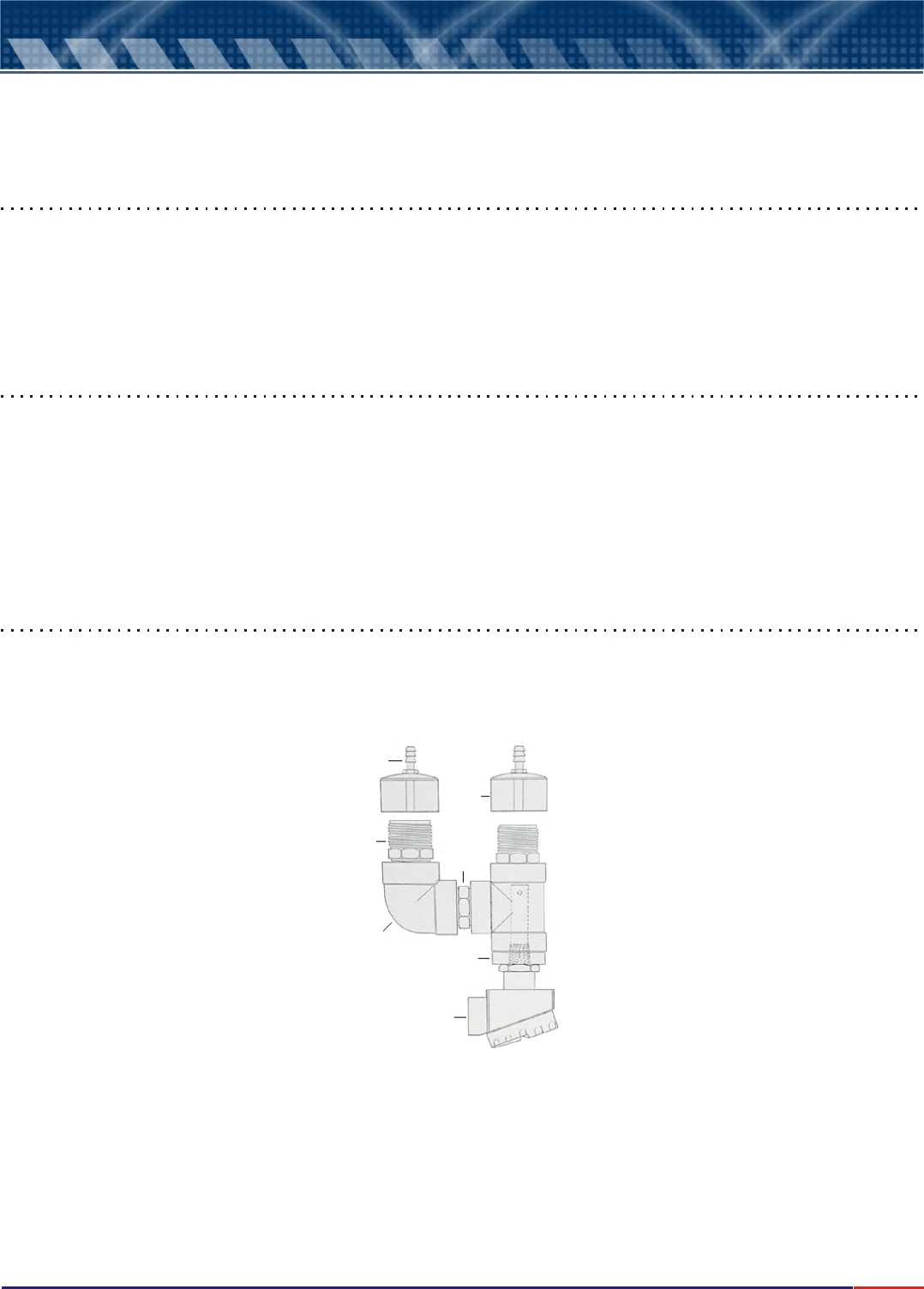

1. Assemble the Transfluency Cell and wash it well.

Conductivity Cell

Reducer 1’’

3/4”

1’’ Elbow

1’’ Nipple

Hose Connection

1” Cap

PVC TRANSFLUENCY

2. Using a 500 mL beaker, place approximately 400 mL of deionized or distilled water. Using a

Conductivity Meter, adjust the conductivity value to approximately 50% of range value,

"contaminating" with high conductivity water (example: tap water).

3. Fill the transfluency with 146.9 uS/cm standard and return to the beaker many times in order to

rinse and eliminate contaminations. Finally leave the transfluency filled with the standard.

4. Verify the standard conductivity value and thru "constant adjustment" reproduce the same read

value at the equipment to be calibrated.

Repeat this operation many times until you can reproduce at least three times the calibrated value.

1’’ Nipple