Operating Manual - WR-5e Remote Control for NE Products

2

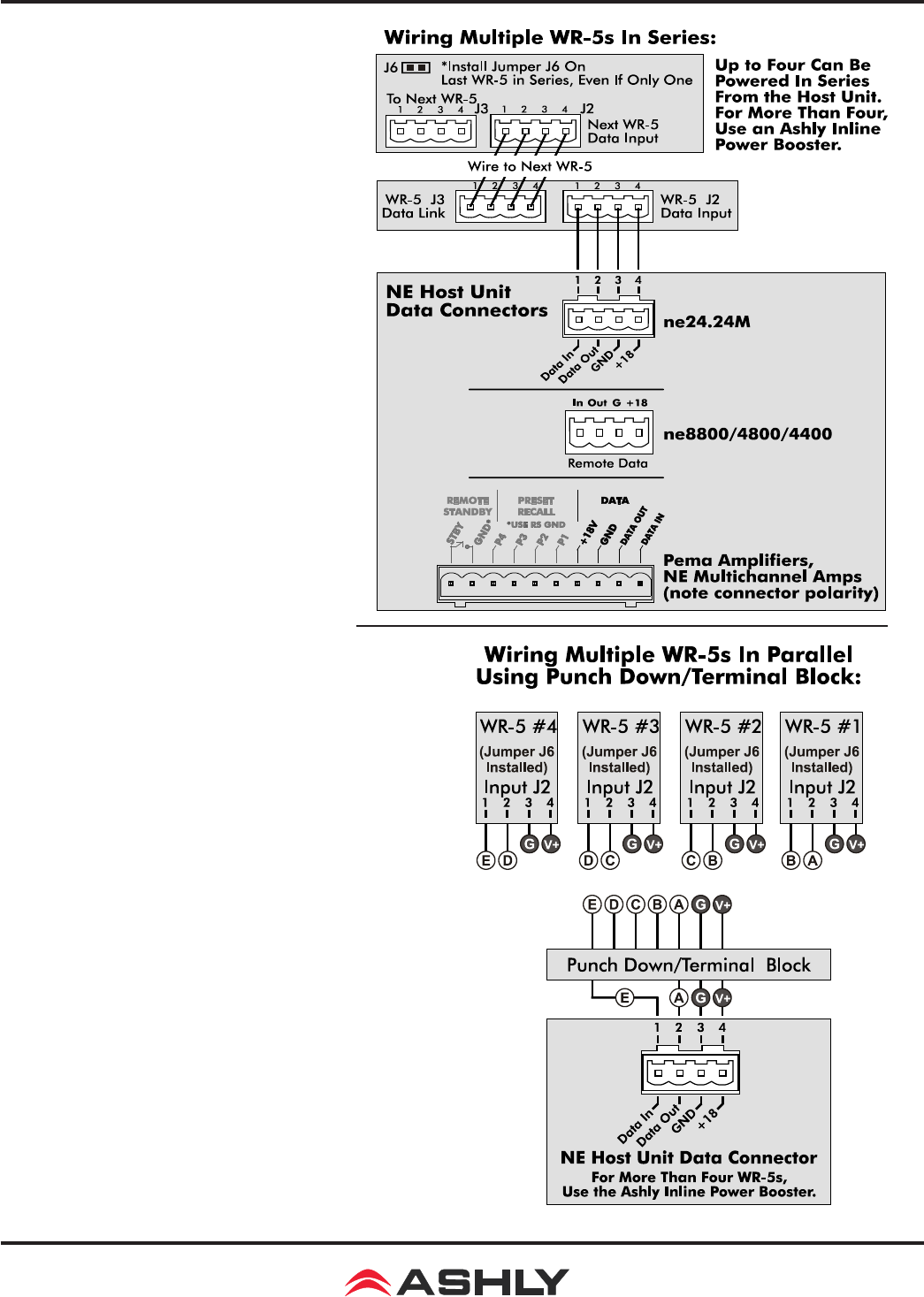

2. Wiring a WR-5e

The WR-5 uses a four conductor

phantom powered serial bus to con-

nect to its host unit or to subsequent

WR-5 units. Up to four WR-5 re-

motes can be powered from one host

unit. Ashly makes an Inline Power

Booster for use in applications that re-

quire more than four WR-5 remotes.

Four conductor telephone wire is

suitable for all wiring, as well as

CAT5, but if shielded wiring is used

be sure to ground the source end of

the shield. Under no circumstances

should shielding be left unconnected

to ground, as the added line capaci-

tance will degrade the data signal.

Wiring in Series: If more

than one WR-5 is being wired in

series, connect the next length of

four conductor bus wire from the rst

WR-5’s “LINK” connector to the

following WR-5 “INPUT” connector,

and so on, until the last WR-5 is wired. On the last

WR-5 in series wiring, and even if there is only one

WR-5, install the female jumper J6 on the back of

the pcb to terminate the serial data bus, and make

sure all prior WR-5 units have that jumper removed.

Maximum cable length for data integrity is 1,000 ft

between the host unit and the rst WR-5, and 1,000

ft between each subsequent WR-5.

Wiring in parallel from a central

location: Some installations are more suited to

wiring multiple WR-5 units from one central loca-

tion rather than daisy-chaining one WR-5 to the

next. Using a punch down block wired to the host

unit’s data connector, each WR-5 uses one four

conductor cable terminated with a single euroblock

connector originating from the punch down block.

The +18 and Ground connections get parallel wired

to each WR-5 (up to four), but the data signal still

gets wired in series In the following manner: Wire

the host unit’s Data Out (pin 2) to the punch down

block, then out from there to the rst WR-5 Data In-

put (J2 pin 2), out J2 pin 1 back to an isolated punch