Dealer Service 23

MAN0306 (Rev. 6/16/2006)

Spool Repair

Whenever repairing spools or positioner, replace valve

spool seals which are included in the spool seal repair

kit.

Disassemble

Remove the joystick assembly and/or single lever con-

trol from valve. Remove the plastic dust cap from posi-

tioner (5, 6). Unscrew the positioner assembly from

valve housing. Push spool (7, 8) out of housing.

Secure spool in vise taking care not to scratch or nick

the outer surface. Unscrew the positioner from spool.

Remove brass sleeve (9) and O-ring (10) from posi-

tioner end of valve housing. Remove O-ring (10) and

flange washer (11) from control lever end of valve

housing. The boom spool has a special sleeve with two

O-rings.

Check spools, replace if nicked and scratched.

Carefully inspect spool bore in valve housing. If deep

scratches or scouring is present, entire valve should be

replaced.

Assemble

Clean threads on positioner and spool. Apply a remov-

able-type thread locking compound to male threads

and assemble positioner to spool. Torque to 85±15 in-

lbs.

Apply clean oil to O-ring (10) and install, along with

brass sleeve (9) on spool housing positioner end. Slide

spool into valve housing. Torque positioner end cap (5,

6) to 70±15 in-lbs.

Reassemble the O-ring (10) and flanged washer (11)

on control lever end of spool. Boom spool does not use

a flange washer.

Position spool wipers (A) (Figure 18) on swing, dipper,

and bucket spools in linkage plate. Reinstall control

linkage. Note the screws installed in the boom and dip-

per spools should be tightened until snug, then backed

off approximately ½ turn to allow free movement of the

joystick.

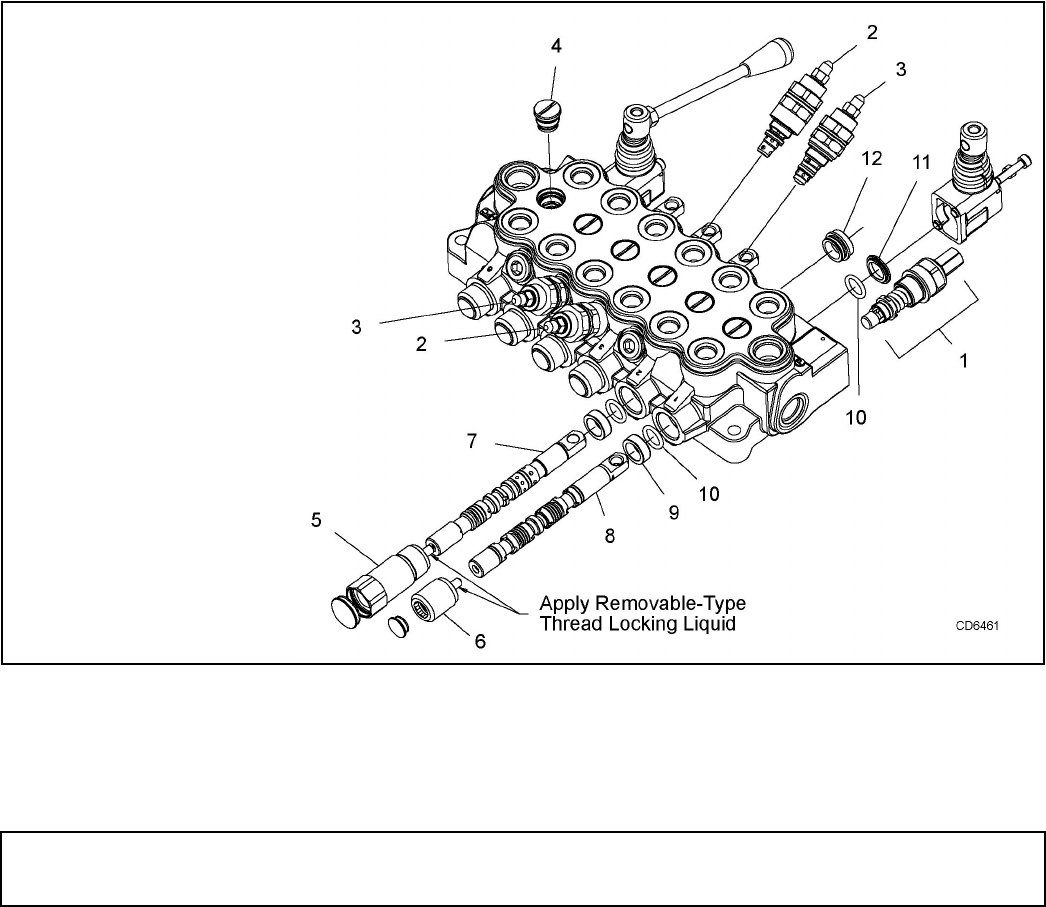

Figure 17. Control Valve Assembly

1. System relief valve 2000 psi

2. Port relief valve with anti cavitation check 2000 psi

3. Port relief valve 2500 psi

4. Load check valve

5. Positioner, 4-position with float

6. Positioner, 3-position

7. Spool, 4-position float (1)

8 Spool, 3-position (5)

9. Sleeve, Lower

10. O-ring

11. Flange washer (5)

12. Sleeve, boom spool (1)