1400 Series Granulators Chapter 5: Maintenance 25 of 43

5-5 Adjusting Belt Tension

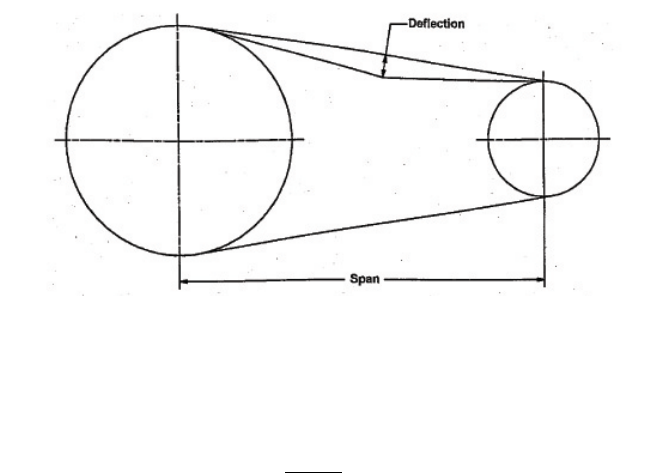

For continuous reliable operation of the granulator, it is important that the belt tension is

correct. Correct tension reduces wear on rotor and motor bearings and keeps belt slip to a

minimum. Figure 2 gives the recommended force to deflect each belt by an amount equal to

the belt span divided by 64. A gauge is available through the sales department to measure the

deflection and force. Use the following procedure to adjust the belt tension:

1. Turn off the granulator at the main isolator switch and remove fuses.

2. Remove the cover to gain access to the belts.

3. Turn the adjusting screw on the motor slide base to tension the belts as required (See

Figure 2).

4. Re-tighten the screws, making sure the pulleys are in correct alignment.

5. Replace the covers.

1. Verify that the alignment of the pulley is correct. Utilizing a straightedge

of sufficient length to span from one pulley to the other, place it along

the sides of both pulleys. The entire face of each pulley should fully

contact the straightedge.

2. Measure the belt SPAN with a measuring tape. Record this dimension in

your note book.

3. Using the deflection tester, apply a perpendicular force at the midpoint of

any one of the belts to deflect the belt 1/64

th

of an inch.

4. Calculate the deflection force:

FORCE[Lb]= SPAN[IN] X (1/64)[Lb/IN]

5. Identify the belt type and measure the small sheave diameter. Look up

the proper model belt deflection force table and find out what the force is

supposed to be.

6. The motor position should be adjusted until the actual deflection force

matches the force listed in the table.