1400 Series Granulators Chapter 7: Appendix 38 of 43

7-5 Feed Roll Assembly

The two counter-rotating pinch rolls in the feed roll assembly control the rate at which

material is to be fed into the granulator. The lower roll is a stationary roll mounted by two

flange bearings and the upper roll, which has its position pneumatically controlled, is

mounted on two slide bearings. The feed roll assembly can accommodate material up to 56”

wide at a thickness range from 0” to 1”.

The feed rolls are driven by a roller chain. The drive system consists of a 2 horsepower 1750

RPM DC drive with a DC motor control. This drive system, combined with a 10:1 gear

reducer, results in a feed rate of 60 ft/minute maximum.

Feed rolls should not be operated any slower than 24ft./min. (18 RPM) for any

period of time. At speeds slower than 24 ft./min., possible overheating of the 2

HP DC drive unit could occur, thus resulting in damage to the drive. If using a

manual tachometer to determine a minimum feed roll speed of 24 ft./min., be

sure to determine feed roll speed and not gear reducer or motor RPM.

Minimum recommended motor speed is 720 RPM (40% of 1800)

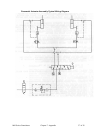

A pneumatic circuit is provided to open and close the feed rolls. This circuit also provides the

pinch pressure between the rolls. The pinch pressure may be varied by adjusting the air

pressure regulator provided in the pneumatic circuit.

The space between the rolls is also variable and should be set to best suit the particular use.

The space between the two rolls should be constant across the entire length of the feed rolls.

Do not run the feed rolls for a long period of time without material being fed through the

rolls. This will result in shorter feed roll life.

Feed Roll Contact Pressure

The contact pressure on material being fed between the rolls is adjustable through the use of

an air pressure regulator in the pneumatic circuit feeding air to the two air cylinders that open

and close the feed rolls. This adjustable regulator may be used to shut off air to the cylinders,

or gradually increase the pressure to the cylinders up to the maximum shop air available, not

to exceed 125 PSI.

Lubrication

When the machine is shipped, the bearings are filled with grease. The bearings should require

no lubrication for a month under usual operating conditions. If the machine is operated

continuously, it may be desirable to lubricate the machine every two or three weeks. The

machine should be lubricated with high temperature ball bearing grease, such as Sun Oil

Prestige #741EP or Mobile Oil Mobilux EP-2.

There are four lubrication points on this feed roll assembly, two upper feed roll bearings, and

two lower feed roll bearings. Also, grease is required on each of the four upper feed roll slide

bearing rails.

No lubrication is required on the feed roll drive chain because it is oil impregnated and

requires no further lubrication.

The oil level in the gearbox should be checked occasionally.