4 HP High-Definition LCD TV Service Manual

• Special information for Pb-free BGA-ICs: These ICs

will be delivered in so-called dry-packaging to

protect the IC against moisture and with the Pb-free

logo on it. This packaging may only be opened

shortly before it is used (soldered). Otherwise the

body of the IC gets wet inside, and during the

heating time the structure of the IC will be destroyed

from steam pressure. If the packaging was opened

before usage the IC has to be heated up for about

90 hours to dry. Make sure you use ESD protection!

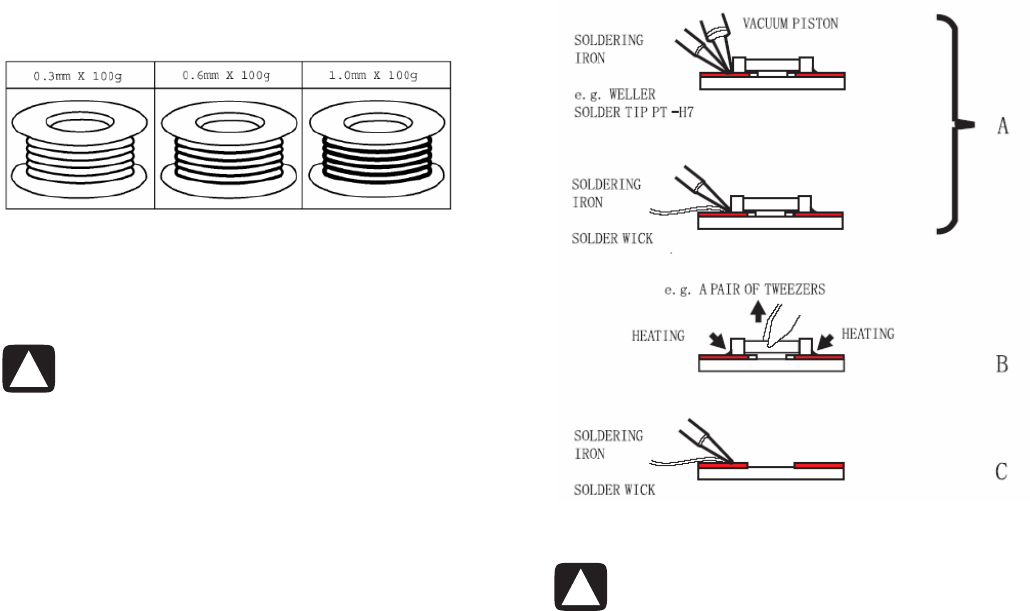

Suggested Pb-Free Solder

Several kinds of Pb-free solder (some shown in the

following illustration) are available for purchase. This

product uses Sn+Ag+Cu (tin (SN), silver (AG), copper

(CU)) solder. However, Sn+Cu (tin (SN), copper (Cu)),

Sn+Zn+Bi (tin (SN), zinc (Zn), bismuth (Bi)) solder can

also be used.

Servicing of Surface-Mounted Devices

(SMDs)

CAUTIONS:

General cautions on handling and storage:

• Oxidation on the terminals of SMDs results in poor

soldering. Do not handle SMDs with bare hands.

• Avoid using storage places that are sensitive to

oxidation, such as places with sulphur or chlorine

gas, direct sunlight, high temperatures, or a high

degree of humidity. The capacitance or resistance

value of the SMDs may be affected by these

conditions.

• Rough handling of circuit boards containing SMDs

may cause damage to the components as well as

the circuit boards. Circuit boards containing SMDs

should never be bent or flexed. Different circuit

board materials expand and contract at different

rates when heated or cooled and the components

and/or solder connections may be damaged due to

the stress.

• Never rub or scrape chip components as this may

cause the value of the component to change.

Similarly, do not slide the circuit board across any

surface.

Removal of SMDs

1 Heat the solder (for 2 to 3 seconds) at each terminal

of the chip. By means of soldier wick and a slight

horizontal force, small components can be removed

with the soldering iron. They can also be removed

with a solder sucker (A).

2 While holding the SMD with a pair of tweezers, take

it off gently using the soldering iron’s heat applied to

each terminal (B).

3 Remove the excess solder on the solder lands by

means of soldier wick or a solder sucker (C).

CAUTIONS:

• When handling the soldering iron, use suitable

pressure and be careful.

• When removing the chip, do not use undue force

with the pair of tweezers.

• The soldering iron to be used (approx. 30 W) should

preferably be equipped with a thermal control

(soldering temperature: 360º to 380º C).

• Once removed, the chip cannot be reused.