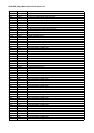

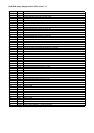

ISSUE

DRAWING NO.

DRAWING TITLE

DATE

Filename:

ECO No. DESCRIPTION OF CHANGE

L925TX_1.1.Sch

DV78 450uH FLYBACK TX

Contact Engineer:

L925TX

8-Oct-2003

INITIALS

Printed:

1 1Sheet of

Notes:

Contact Tel: (01223) 203200Kevin Lamb

A & R Cambridge Ltd.

Pembroke Avenue

Cambridge CB5 9PB

Waterbeach

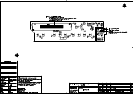

VIEW FROM TOP OF PART

ELECTRICAL REPRESENTATION

WINDING DETAILS

WINDING WIRE DETAILS

START END

NOTE PIN NUMBERING CONVENTION

MATERIALS

CORE PQ32/30 in PC44 MATERIAL (OR EQUIVALENT)

BOBBIN

ASSEMBLY DETAILS

PART TO BE MARKED WITH PART NUMBER / ISSUE NUMBER

1

2

3

4

5

7

10

11

12

PRIMARY1

PRIMARY2

SECONDARY1

SECONDARY2

SECONDARY3

SECONDARY4

SECONDARY5

PRIMARY2

SECONDARY1

SECONDARY2

SECONDARY4

SECONDARY5

9 10

7 8

11 12SECONDARY3

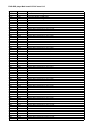

PIN # PIN #TURNS

41

41

14

10

22

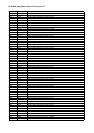

WINDING ARRANGEMENT ON BOBBIN

PRIMARY1

PRIMARY2

SECONDARY5

SECONDARY1 SECONDARY2

SCREEN2

SCREEN1

+

1 FULL LAYER WIND AS BIFILAR PAIR

WIND SECONDARY 4 FIRST THEN SECONDARY 3 IN THE GAPS

SCREEN TO BE HIGHEST POSSIBLE RESISTANCE FOIL FOR LOWEST LOSSES. (I.E. FOIL AS THIN AS POSSIBLE)

CORE TO BE GAPPED IN CENTRE LEG TO GIVE REQUIRED Lpri (GAP APPROX 0.4mm)

(Lpri = 450uH +/- 10% PRIMARY INDUCTANCE MEASURED FROM PIN 1 TO 3 )

A.0

Prototype Release

KAL 20-11-02

6

8

9

ID OD

ENAMELLED COPPER WIRE

No PER

CABLE

1

1

1

2

1

0.25mm 4 5

5 6

SEC1 AND 2 WOUND AS BIFILAR PAIR ACROSS FULL WIDTH

1 FULL LAYER

INTERNAL SCREENS TO BE FULL WIDTH. CONNECTION TO SCREEN VIA SOLDER JOINT TO COPPER (SEE DIAGRAM)

SOLDER JOINT TO BE ARRANGED TO PRODUCE A LUMP IN THE CORE WINDOW

INSULATOR

WIRE

SOLDER JOINT TO BE COVERED IN TAPE

SOLDER JOINT TO MADE MADE TO CLEAN COPPER AND JOINT TO BE TAPED.

BUMP FROM SCREEN JOINT TO BE

TO MINIMISE LOSS OF WINDING HEIGHT

FULL WINDING WIDTH

FOIL (2mil OR THINNER)

JOINT MUST BE MADE TO CLEAN COPPER

(I.E. NOT THROUGH MYLAR INSULATOR)

WITH PART INSTALLED IN PCB

1

2

ARRANGEMENT OF INTERNAL FOIL SCREENS

ADJACENT TO CORE WINDOW

NOTES

WIND SEC1 AND SEC2 AS A BIFILAR PAIR ACROSS

SCREEN 1 1 INSULATED 2mil COPPER FOIL

SCREEN 2

3 WINDINGS WILL BE A TIGHT FIT ON BOBBIN. NOTES AND WINDING ARRANGEMENT SPECIFIED TO BE ADOPTED.

1 FULL LAYER

ENAMELLED COPPER WIRE

ENAMELLED COPPER WIRE

ENAMELLED COPPER WIRE (BIFILAR)

ENAMELLED COPPER WIRE

1.2 INCH

1.1 INCH

MAXIMUM OVERLAP ON ENDS OF

SCREENS TO BE LESS THAN 1mm

TO MINIMISE CAPACITIVE COUPLING

WHICH WOULD PRODUCE SHORTED

TURN FOR HIGH FREQUENCY CURRENTS

1

2

SCREEN TO BE MADE FROM MAXIMUM 0.05mm (2MIL) FOIL

0.3mm

2 LAYERS MYLAR TAPE

SECONDARY4

3 216 1 0.8mm 0.86mmENAMELLED COPPER WIRE

1 INSULATED 2mil COPPER FOIL

2 1PRIMARY1 16 1 0.8mm 0.86mmENAMELLED COPPER WIRE

0.72mm0.66mm

0.72mm0.66mm

0.25mm 0.3mm

0.25mm 0.3mm

WHOLE BOBBIN WIDTH

WIND AS A BIFILAR PAIR ACROSS WHOLE BOBBIN WIDTH

SPACE WINDING ACROSS WHOLE BOBBIN WIDTH

WIND ACROSS WHOLE BOBBIN WIDTH BETWEEN GAPS IN SEC4

SPACE WINDING ACROSS WHOLE BOBBIN WIDTH

SPACE WINDING ACROSS WHOLE BOBBIN WIDTH

SCREEN TO HAVE NO OVERLAP AT ENDS

1

2

3

4

5

7

10

11

12

6

8

9

SECONDARY3+

SOLDER JOINT TO BE MADE HALF WAY ALONG LENGTH OF THE FOIL

PART NUMBER TDK PC44PQ32/30Z-12 (OR EQUIVALENT)

PART NUMBER TDK BPQ32/30-1112CP (OR EQUIVALENT)

CLAMP PART NUMBER TDK FPQ32/30-A (OR EQUIVALENT)

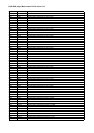

4 TRANSFORMER TO BE FITTED WITH AN OUTER COPPER SCREEN WRAPPED AROUND THE OUTSIDE OF THE

SOLDER JOINTS TO BE MADE HALF WAY3

ALONG LENGTH OF FOIL FOR REDUCED LOSSES

5 PIN 1 ON BOBBIN TO BE MARKED WITH WHITE PAINT (OR OTHERWISE)

THIS MARKING TO BE USED TO ORIENTATE TX DURING WINDING PHASE TEST

TRANSFORMER IS TO BE USED ON SECONDARY SIDE OF MAINS

ISOLATION BARRIER (I.E. THIS TRANSFORMER IS NOT REQUIRED

TO PROVIDE MAINS ISOLATION BARRIER)

MAXIMUM VOLTAGE BETWEEN WINDINGS <60V

PIN 1 TO BE MARKED

NOTE.

SCREEN TO HAVE NO OVERLAP AT ENDS

7

2

3

16T

16T

22T

14T

10T

8

1 11

10

9

12

4

41T

41T

5

6

SCR

TX2

Ferrite Switch Mode

L925TX

02_E336

B.0

Changed Pri1,2 and Sec1,2 turns, Lpri & gap, Added outer screen

KAL 21-03-0302_E086

6 100% PHASE TEST AND ISOLATION TEST TO BE CARRIED OUT ON ALL WINDINGS.

OF THE TRANSFORMER CORE AND CONTACTING THE METAL CORE CLAMP THUS FORMING A SHORTED TURN

SCREEN TO BE 10THOU COPPER STRIP 6 to 8mm WIDE AND FITTED OVER THE JOIN OF THE CORE HALVES.

TO LEAKAGE FLUX. SEE DIAGRAM

SCREEN TO BE COVERED IN A LAYER OF TAPE.

6 to 8mm 10THOU COPPER

OUTER SCREEN

ELECTRICALLY CONNECTED TO CORE CLAMP

CONDUCTIVE ADHESIVE FOIL MAY BE USED

FOIL TO BE COVERED IN A LAYER OF MYLAR TAPE

SHORTED TURN FOIL SCREEN TO BE

1.0

Production Release

KAL 02-07-03

02_E195

1.1

'VIEW FROM SIDE OF PART SHOWING PIN LENGTH DIMS' added.

SLS 06-10-03

03_E290

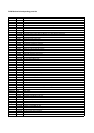

SEE VIEW GIVING PIN

LENGTH DIMENSIONS

VIEW FROM SIDE OF PART

SHOWING OUTER FOIL SCREEN

VIEW FROM SIDE OF PART

SHOWING PIN LENGTH DIMENSIONS

PCB

MATING FACE OF TX

7 REF.

2.5 MAX