3.3 Pump control and latching alarms

The output relay of the MCU200 can be latched into the de-

energised state. This latch is achieved by short circuiting the

two terminals of the Auxiliary input, labelled as terminals 3 &

4 on the pc board (see figure 5). The relay will remain de-

energised while the latching short circuit is applied. Only

after this circuit is broken can the relay re-energise under the

control of the sensor.

A latching alarm can therefore be achieved by connecting one

pole of the output relay into the auxiliary input, through a

push to break “reset” button. NC1 and C1 should be used to

create this latch, with NC2, C2 and NO2 being used for the

external alarm circuit.

For a pump control application, switching a pump to control a

liquid between two sensors in a tank, this auxiliary input can

be used to monitor the second sensor. The control system

must be designed as follows:

(i) The pump to be latched “on” must be driven by the

MCU200 output relay.

(ii) The sensor attached directly to the MCU200 must

initiate the pump action to be latched.

(iii) The latched pump action occurs when the MCU200 relay

is de-energised.

(iv) The separate sensor must be used to detect the liquid

presence at the switch off point.

(v) The signal from the separate sensor to switch off the

pump must be an open circuit, and is connected to the

auxiliary input in the MCU200.

3.2.3. High level alarm, Hisens sensor

The Hi-Sens sensor oscillates when the sensor is dry, so

producing a fail safe high level alarm. Normally such systems

have the relay de-energising for alarm. This example has time

delay of 30 seconds to Normal to allow the operator to identify

any tank giving an occasional alarm.

Note that all Hisens sensors are 1 MHz and that cable check

circuit is out - firstly because it does not function with Hisens

but secondly that a cable fault with Hisens will produce an

alarm signal anyway.

Gain adjustment:

(i) With sensor dry, reduce time delays to 2 seconds for

simpler adjustment. Set gain switch to “LO” and reduce pot

to “MIN”. Red LED will illuminate - this is the “false wet”.

Rotate the gain potentiometer clockwise slowly until the green

LED illuminates: note the setting (X).

(ii) Increase the gain setting X + 3 if it is necessary to switch

to the “HI” gain range, re-check for a “false wet” position on

the “HI” range, or assume an overlap between “LO” and “HI”

of 2 divisions of gain.

(iii) Check that the sensor when immersed in water gives an

alarm output. Recheck in the liquid to be monitored.

(iv) Reset the time delays as needed.

Special site conditions:

In the above application the time delay can be used to

prevent high level alarms caused by splashing of the sensor, by

setting the green switch to “Delay to NE”. Avoiding severe

splashing or condensation effects may require a slight increase

in the gain setting to X + 4. To detect splashing or for use on

light oils the gain can be reduced to X + 2.

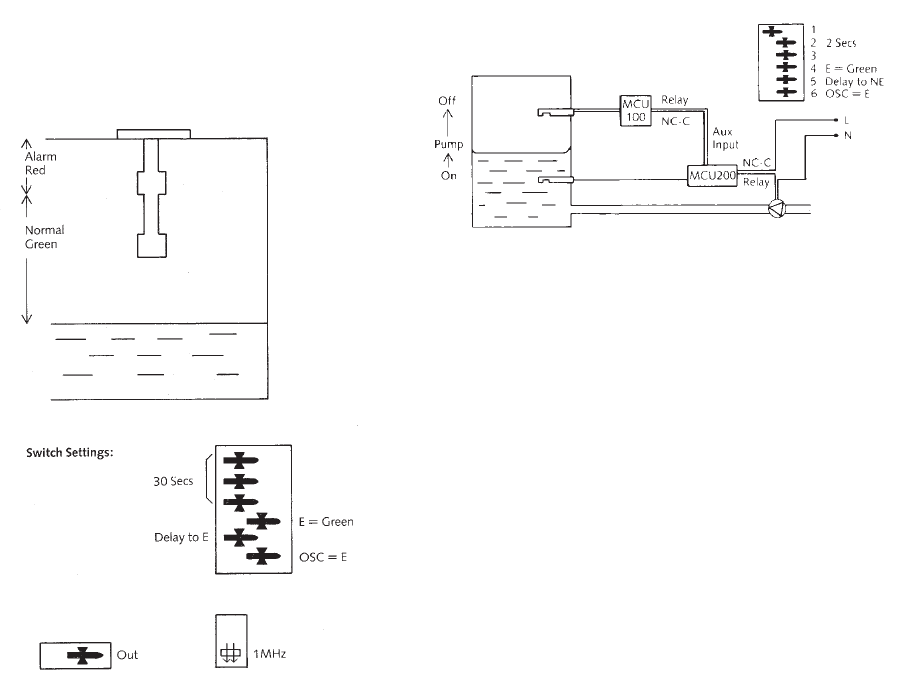

Fig. 12 Tank filling pump control

In this example the number 6 switch (blue) on the MCU200

would be set to OSC = E, so that when the lower gap sensor

sees air it de-energises the relay to bring on the pump. With

switch number 4 (yellow) set to E = GREEN, the red LED

illuminates when the pump is running. With “Delay to NE”

set at 2 seconds, the sensor will ignore occasional bubbles or

surface turbulence which could trigger a pump start.

The high level sensor, illustrated as a Mobrey MCU200 plus

sensor, could alternatively be a Mobrey 005, or another

MCU200 or a float operated level switch: all will give a volt

free contact output suitable for the auxiliary input on the

lower MCU200.

Fig. 11