3.4.3. Interface detection between two immiscible similar

liquids

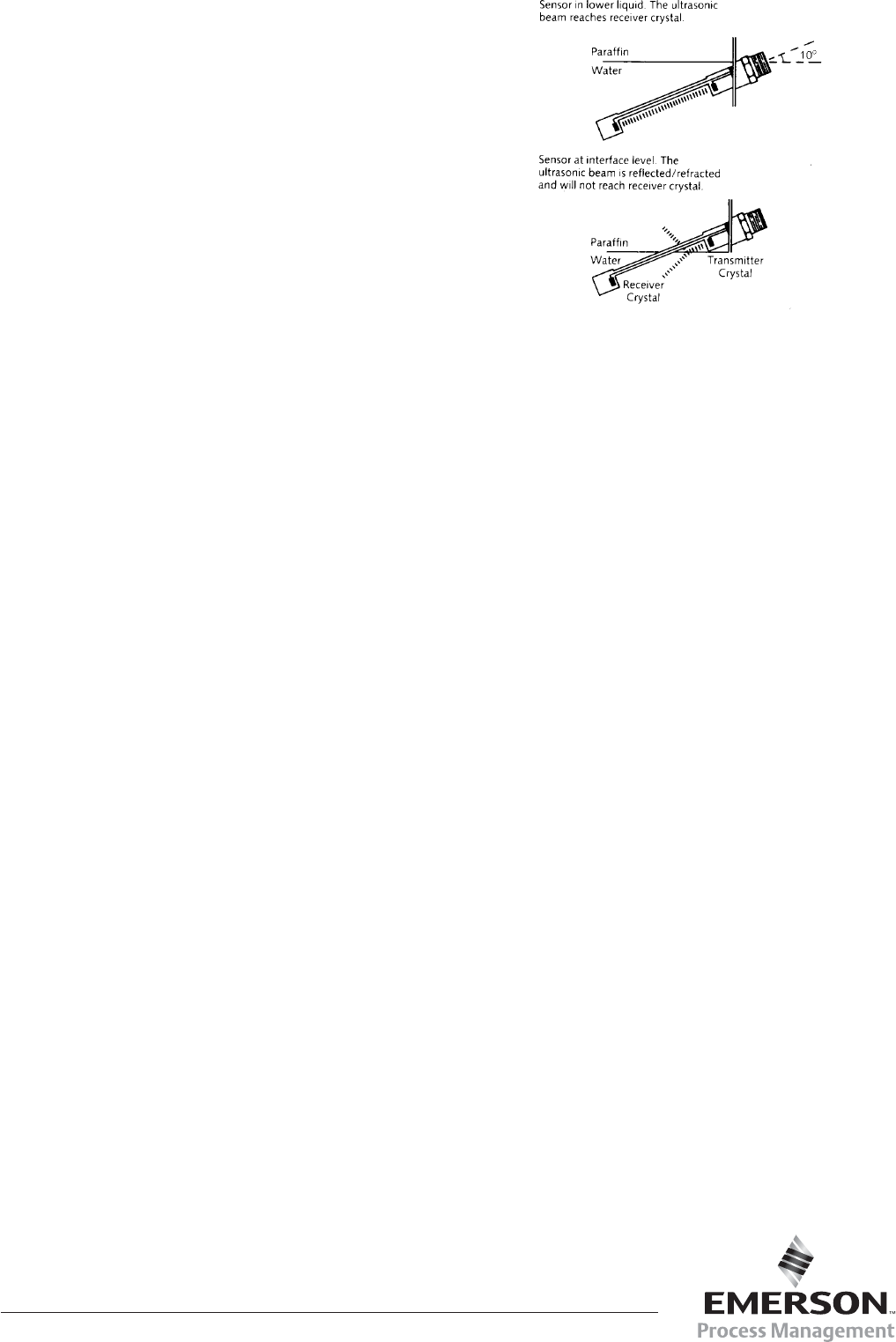

When liquids are ultrasonically very similar - as happens for

example with paraffin and water - the procedure in section

3.4.2. produces very little difference between the two “false

dry” points. In this case the “reflection” method of interface

detection is used.

If an ultrasonic beam is transmitted from one liquid to another

at a suitable angle (10%) it is split at the interface into a

reflected and a refracted beam, so that it does not reach the

receiver crystal. If there is no interference in the gap, but

only one liquid, the beam is received and the sensor oscillates.

The gain adjustment is made so that the gain is 3 divisions

higher than the highest false dry position obtained, as in

section 3.4.2. Performance at the interface should then be

checked.

Note that the non oscillating state of the sensor, at the

interface, also occurs throughout any emulsion layer at the

interface, and also when the sensor is in air.

Fig 16 Interface detector by reflection method

a) For a gap sensor giving false dry indication, this could

possibly be due to aeration or solids in the liquid. This can

be overcome by increasing the gain slightly, to a maximum

of X-2. This increases the sensitivity and is appropriate for

high level alarms.

b) For a gap sensor giving false indication, this could be

due to cross talk between cables - check that all junctions

use coax connectors with the outer casings isolated.

Seperate the two coax cables for long cable runs. False wet

can also be caused by viscous liquids clinging to the

sensor: sensitivity can be decreased slightly by reducing the

gain to X-6 minimum - check for reliable operation in the

liquid.

c) For a Hisens sensor the gain adjustment is slightly more

critical, as quoted in 3.2.3. Sensitivity is increased by

reducing the gain to X+2. Decreasing sensitivity, sometimes

necessary to avoid condensation, is achieved by increasing

the gain to perhaps X+4.

The Hisens sensor can take 30 seconds or more to drain

off surface coatings and re-instate a dry signal in viscous

liquids.

d) Check for correct sensor operation whenever the gain is

adjusted away from the normal set point. Assume an

overlap of 2 divisions between the "LO" & "HI" gain ranges.

(iv) Check the incorrect operation has not been produced

by incorrect setting of the frequency selection switch or an

external short circuit on the auxiliary input terminals.

(v) The circuit board can be checked by linking the sensor

terminals 1 and 2 with a wire, to simulate an oscillating

sensor.

4. Maintenance

5.1 The following parts are suitable for replacements on

the MCU201.

Main pcb complete K2641

LED indicator pcb K2643

LED pcb spacers K2623

LED pcb connector K2624/50

Box assembly K2662

Gland assembly K746/K747/K748

There are no consumable items such as fuses.

5.2 Fault Finding

(i) At least one LED should be illuminated. If not check

the power supply to the unit.

(ii) If the “Fault” LED is on and the sensor is a standard

Mobrey 300 series or a 402/422/433, check the coax

cable to the sensor for incorrect wiring or damage.

Particularly check continuity of extension cables,

connection of crimped connectors on cable ends. For

other types of sensor switch the cable check circuit “OUT”

- (see section 2). The pcb board can be checked by

linking the two terminals labelled E on the sensor

terminals - this should cancel the fault indication LED.

(iii) If the sensor is giving incorrect indications check the

gain adjustment (see section 3).

5. Spares and fault finding

Safety maintenance: This is limited to periodic inspection

by a qualified person to ensure that the installation

including wiring and equipment housing is safe.

abcdef

International:

Emerson Process Management

Mobrey Measurement

158 Edinburgh Avenue,

Slough, Berks, SL1 4UE, UK

T +44 1753 756600

F +44 1753 823589

www.mobrey.com

The Emerson logo is a trade mark and service mark of Emerson Electric Co.

Mobrey is a registered trademark of Mobrey Ltd.

All other marks are the property of their respective owners.

We reserve the right to modify or improve the designs or specifications of product and services at any time without notice.

Americas:

Emerson Process Management

Rosemount Inc.

8200 Market Boulevard

Chanhassen, MN USA 55317

T (US) (800) 999-9307

T (International) (952) 906-8888

F (International) (952) 949-7001

Manual reference : IP227 Rev AA, July 2007