Assist Gas Recommendations

The machine has provision for three kinds of assist gases. The assist gas inputs are at the

rear of the machine. The inputs are labeled OXYGEN, CLEAN CUT, and AIR.

Oxygen is normally used to cut steel and stainless steel.

Nitrogen is used to Clean Cut™ stainless steel and aluminum with an oxide free edge.

Shop air can be used to cut aluminum at reduced cost (see page 26).

Two-stage regulators and hoses are provided in the gas connection kit for the oxygen and the

nitrogen. For high-volume/frequent use, cutting gases should be purchased in liquid form.

Note that the liquid gases will “boil-off” at some minimum rate, even if not used. Gases which

are used in low volume or infrequently should be bought in high-pressure bottles rather than in

liquid form.

An evaporator will be needed when using liquid high-pressure Nitrogen.

For usage and pressure requirements, contact Amada America’s Laser Group.

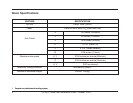

Gas Assignment Inlet Port

Oxygen OXYGEN

Nitrogen CLEAN CUT

Shop air AIR

LC3015 Theta User Installation Guide - October, 2003 11

Oxygen Purity

When cutting carbon steel with oxygen, higher purity means higher speed.

“Increasing the oxygen purity from 99.7% to 99.9% resulted in a cutting speed increase in ex

-

cess of 10%.” according to the BOC article referenced below.

For a great discussion on assist gas purity, see BOC article - gases and lasers

J T Gabzdyl &

D Sullivan - Presented to Lumonics User Group, Minneapolis USA, May 1996