The Chiller

The chiller is very important to the reliable operation of your laser cutting machine.

q

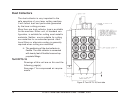

The chiller must be placed so that an adequate flow of air is maintained.

q

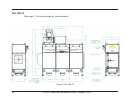

The positioning of the chiller is flexible. Two lengths of flexible hose and appropriate fittings are

provided for connection to the system.

q

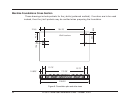

If you plan to hard plumb the system, use only Brass, Stainless Steel, and/or Plastic.

Black steel or Galvanized pipe and fittings are not permitted.

If the system is hard-plumbed, the total restriction of piping and fittings must not add up to more

restriction than the standard flexible hose and fittings would have.

q

The chiller is a closed loop system, but requires periodic addition of water and/or additives to re-

place evaporative losses.

q

The chiller must be filled with proper coolant mixture. See page 7 for details.

DO NOT FILL THE CHILLER WITH CITY WATER, OTHERWISE SERIOUS AND

EXPENSIVE DAMAGE MAY BE INFLICTED ON THE LASER OSCILLATOR

16 LC3015 Theta User Installation Guide - October, 2003