HP High-Definition LCD TV Service Manual 3

• Be sure to handle the circuit board by holding the

large parts such as the heat sink or transformer.

Failure to observe this precaution may result in the

occurrence of an abnormality in the soldered areas.

• Do not stack the circuit boards. Failure to observe

this precaution may result in problems resulting from

scratches on the parts, the deformation of parts, and

short-circuits due to residual electric charge.

• Routing the wires and fixing them in position must

be done in accordance with the original routing and

fixing configuration when servicing is completed. All

the wires are routed far away from the areas that

become hot (such as the heat sink). These wires are

fixed in position with the wire clamps so that the

wires do not move, thereby ensuring that they are

not damaged and their materials do not deteriorate

over long periods of time. Therefore, route the

cables and fix the cables to the original position

and states using the wire clamps.

• Perform a safety check when servicing is completed.

Verify that the peripherals of the serviced points

have not undergone any deterioration during

servicing. Also verify that the screws, parts, and

cables removed for servicing purposes have all

been returned to their proper locations in

accordance with the original setup.

• A glass plate protects the LCD display. This glass

plate can be cleaned with a slightly moist cloth. If

dirt appears between the glass plate and the LCD

display panel have only a qualified service

employee clean it.

Repair Tips

WARNING: All ICs and many other

semiconductors are susceptible to electrostatic

discharges (ESDs). Careless handling during repair

can be life-threatening. When repairing, make sure

that you are connected with the same potential as

the mass of the unit via a wrist wrap with

resistance. Keep components and tools also at the

same potential.

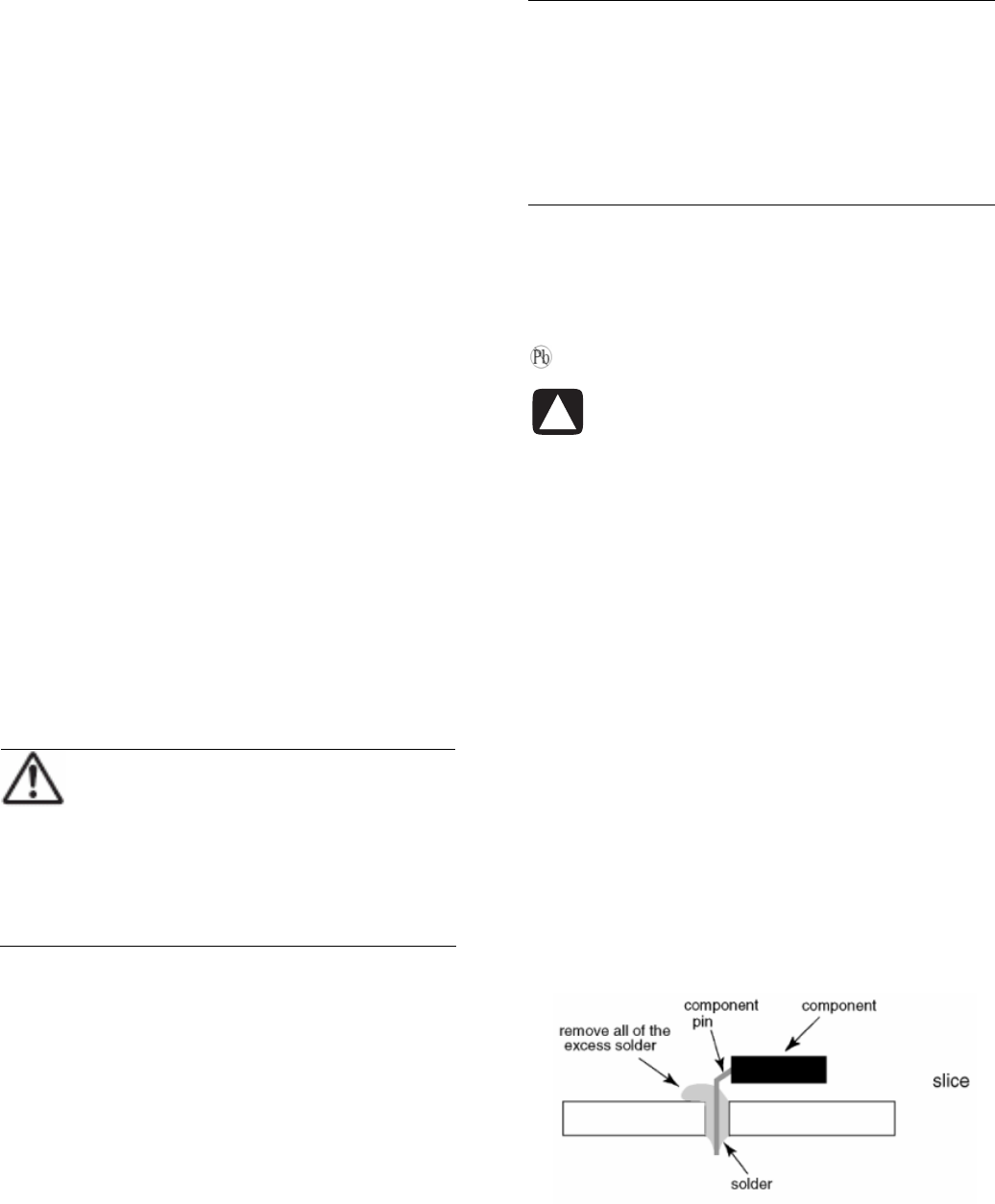

About Lead-Free Solder

NOTE: LEAD IS LISTED AS (PB) IN THE PERIODIC

TABLE OF THE ELEMENTS. IN THE INFORMATION

THAT FOLLOWS, PB WILL REFER TO LEAD SOLDER,

AND PBF WILL REFER TO LEAD-FREE SOLDER. THE

LEAD-FREE SOLDER USED IN OUR MANUFACTURING

PROCESS AND DISCUSSED HERE IS (SN+AG+CU).

THAT IS TIN (SN), SILVER (AG), AND COPPER (CU),

ALTHOUGH OTHER TYPES ARE AVAILABLE.

This model is manufactured using Pb-free solder for the

sake of environmental conservation. For service and

repair work, we suggest using Pb-free solder as well,

although Pb solder may be used.

PCBs manufactured using Pb-free solder have the sign

stamped on the PCB.

CAUTIONS:

• Pb-free solder has a higher melting point than Pb

solder. Typically the melting point is 50–70ºF

(30–40°C) higher. Use a high temperature soldering

iron. Adjust your solder tool so that a temperature

around 360–380ºC is reached and stabilized at the

solder joint. Heating time of the solder joint should

not exceed 4 seconds. Avoid temperatures above

400ºC; wear-out of tips will rise drastically and flux-

fluid will be destroyed.

• Pb-free solder will tend to splash when heated too

high (about 1,100ºF or 600ºC).

• Mix of Pb-free solder Tin (SN)/parts with leaded

soldering Tin (SN) in/parts is possible but not

recommended. If you have to use Pb solder,

completely remove all of the Pb-free solder on the

pins or solder area before applying Pb solder. If this

is not practical, be sure to heat the Pb-free solder

until it melts, before applying Pb solder.

• After applying Pb-free solder to double-layered

boards, check the component side for excess solder

that may flow onto the opposite side (see the

following illustration).