18

Always disconnect power and air when servicing the unit. Please read the

Operation Manual thoroughly before attempting to

operate the STP.

SYMPTOM RECOMMENDATIONS

• Unit does not turn on. ✔ Check electrical connections.

✔ Check electrical supply.

✔ Check fuses.

• Unit does not cycle. ✔ Make sure unit is in ready mode.

✔ Check air supply and connections.

✔ Make sure cable is making contact with trigger.

• Unit does not strip wire. ✔ Straighten wire to hit trigger.

✔ Check for proper control settings.

✔ Consult IDEAL for wire applications.

✔ Check blade for proper heating.

• Slug does not pull off. ✔ Check for proper PRESSURE setting.

✔ Check air supply. Set at 100 PSI.

✔ Check rear grip for slug debris.

✔ Check rear grip pads. Replace if worn.

✔ Check for proper strip length.

✔ Axial cut of insulation may be required.

Consult IDEAL for wire application support.

Preventative Maintenance

The STP requires very little maintenance aside from changing blades and

gripper pads.

Visually inspect threaded rods and guide rods. If they look dry, lubricate

with a light machine oil.

Remove slug debris from unit.

Replace nylon cable chains (2) as required.

Cleaning Your STP

Note: Disconnect power and air when cleaning the unit.

Clean front gripper pads and holder with rubber roller cleaner.

Clean rear gripper pads and holder with rubber roller cleaner.

Remove debrise from both front and the backside of the entry gate with a clean cloth.

Empty the lsug tray in a timely manner.

Clean the outside case of the STP with mild detergent.

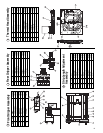

Changing Slug Tray Location

The STP slug tray may be repositioned:

1. Disconnect power.

2. Disconnect air.

3. Do not invert machine or gripper pins might fall out.

4. Remove screw, move to opposite side.

5. Secure slug tray by replacing screw.

Tips and Trouble Shooting

SYMPTOM RECOMMENDATIONS

• Wire not cut completely. ✔ Check for proper HEAT setting.

✔ Check for proper SPEED setting.

✔ Check for proper blade movement.

✔ Check condition of blades. Replace if necessary.

✔ Check for proper. blade connections.

✔ Consult IDEAL for wire applications.

• Wire slips further into ✔ Check for proper PRESSURE setting.

machine when gripper ✔ Check front grip pads. Replace if worn.

attempts to pull off ✔ Axial cut of insulation may be required.

slug. Consult IDEAL for wire application support.

• Unit cycles repeatedly. ✔ Make sure slugs are not in contact with trigger

block.

✔ Check for obstruction at trigger.

✔ Check and empty slug tray.

✔ Make sure slug is not in contact with trigger.

• Wire will not fit into unit. ✔ Straighten excessive curl in wire.

✔ Make sure unit is in ready mode.

✔ Check for obstruction in wire path.

✔ Check all grip pads for proper fit.

All of the cylinders, solenoids and sensors may be tested individually. Please

refer to the TEST section on page 10. Operate each individual component to

determine the status. Repair and or replace components as required.

OIL RODS WHEN DRY

STP Service continued