5

STP Operating Principles and Terms (continued)

SPEED: Thermal Head Rotation

SPEED refers to the rate of rotation by the Thermal Head of the STP. This is the rate at which the blades are rotated about the wire being stripped. The

slowest speed is 1 and 10 the highest.

Running at a faster speed requires a higher blade heat setting which may shorten the blade life. A superior strip quality is obtained at lower blade HEAT

and SPEED settings. However, the various types and thicknesses of insulation material requires a wide variety of HEAT and SPEED setting

combinations (to avoid touching the inner braid).

PRESSURE: Rear Grip Mechanism

The PRESSURE setting regulates the air pressure delivered to the internal, rear grip mechanism. This mechanism is used to pull the stripped slug off

the wire. Based on a line pressure of 100 PSI, which is required for operation of the unit, the internal rear grip can be set to operate from 5 PSI to

100 PSI in increments of 5 PSI. Various insulation materials and shield types require varying grip pressures to obtain optimal slug removal results.

The rest of the machine runs on a constant 100 PSI line pressure.

Having air pressure controlled electronically allows the STP to use a variable amount of grip force to hold the insulation slug while trying to pull off the

slug. This is important for three reasons. First, various materials adhere to the braid differently and require more or less grip pressure to be pulled from

the shield. Excessive grip pressure increases internal friction between the slug and shield, preventing removal of the slug. Second, different materials

have varying coefficients of friction with the grip pads. This creates the need for a wide variety of grip PRESSURE settings. Finally, the strip length

affects the amount of grip pressure required.

STRIP LENGTH

The strip length range of the STP is from 1.25 to 6.00 inches (31 to 150 mm). It can be set in increments of .01 in. or 1 mm. The strip length

required for a given wire is a user-defined variable.

Longer or shorter strip lengths may require varying grip PRESSURE settings. Once the STP is set to strip 3.00 inches or longer the grip PRESSURE

setting remains fairly constant for a given wire type. However, when stripping less than 3.00 inches it may be necessary to increase the grip

PRESSURE setting. This is due to the fact that the internal, rear grip mechanism is about 4.00 inches long and consists of separate pressure points.

When less than 3.00 inches is to be removed, the grip mechanism is not fully utilized and may require a higher PRESSURE setting to accomplish the

task.

Any given wire may be successfully stripped over a range of setting combinations. It is important to look at all of the variables and resulting

performances in order to select the combination that best suits the specific stripping requirements.

IDEAL INDUSTRIES, INC. offers free application assistance... for immediate assistance, call our technical service hotline at 1-800-338-4495.

STP Operation

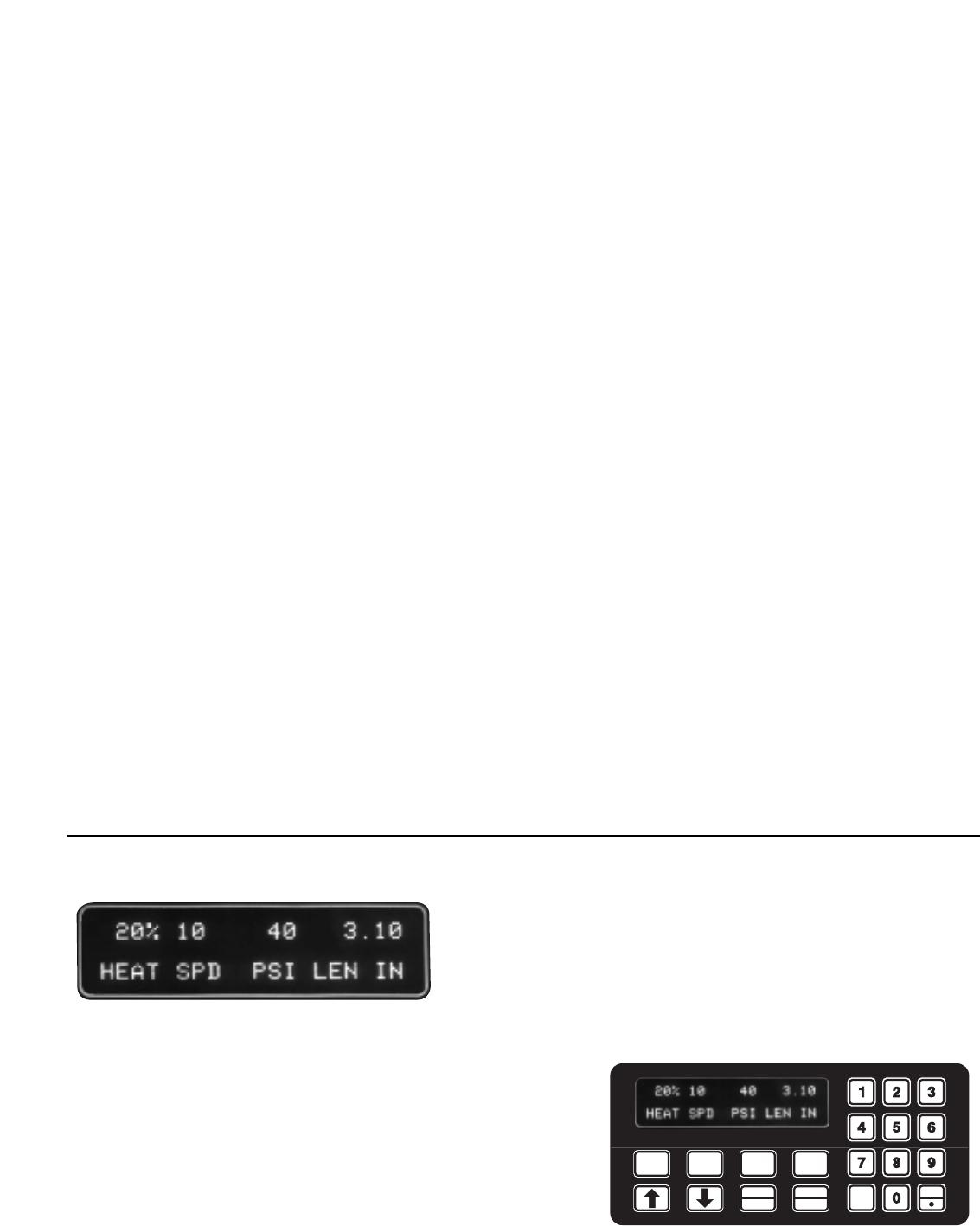

When the machine is turned on, the software version is briefly displayed followed by

the machine initializing.

Then the Machine Status display appears showing the present settings. During

operation there are three different status displays: READY MODE, “ENTER VALUE”

(a value is being entered or the machine is adjusting to a new value) and “CYCLE IN

PROGRESS” (the machine is in a strip cycle).

At this point, you can proceed stripping wire, enter new values or retrieve a preset batch

with different settings.

Use the following procedures to change the machine settings via the

control panel keeping in mind the “Operating Principles and Terms”

described on page 4, while selecting process variables.

All control settings can be set by either using the arrow keys or setting

discrete values on numeric key pad.

Example: Ready Mode Display

STRIP

LENGTH

COUNT

CLEAR

PRESSURE

PRGM.

HIGH

SPEED

HEAT

ENTER

BATCH