4

STP Service Setup Continued

Electrical Connection Requirements

Voltage Selection

The STP operates on either 115V/230V AC; 45-930, 115V AC 4A 60 Hz ; 45-935, 230V AC 2A 50 Hz. Proper voltage will be preset at the factory.

Fuse Replacement

Disconnect power cord and remove the fuse cartridge using a small blade screwdriver or similar tool. Replace two fuses with recommended fuses.

45-930, 4AT 250V, 1/4” x 1-1/4”; 45-935, 2AT 250V, 5 mm x 20 mm, insert the fuse cartridge back into the unit making certain the proper voltage is

selected.

On-Off Switch — Located on the back of the unit, the on/off switch controls the main

electrical power supply.

Air Connection Requirements

Connect

1

/4" coiled air hose to the air inlet fitting located on the back of the unit. This is a reusable compression type fitting.

To connect air hose:

1. Disconnect electrical power supply.

2. Connect the air hose by inserting it firmly into compression fitting.

Air must be clean, dry and pressure regulated to 100 PSI.

The STP consumes approximately 50 cubic inches (about .03 cubic feet) of compressed air per cycle. Total air volume consumed depends on frequency

of operation.

To disconnect air hose;

1. Disconnect electrical power supply.

2. Disconnect air supply.

3. Depress the red ring

and pull on the air hose.

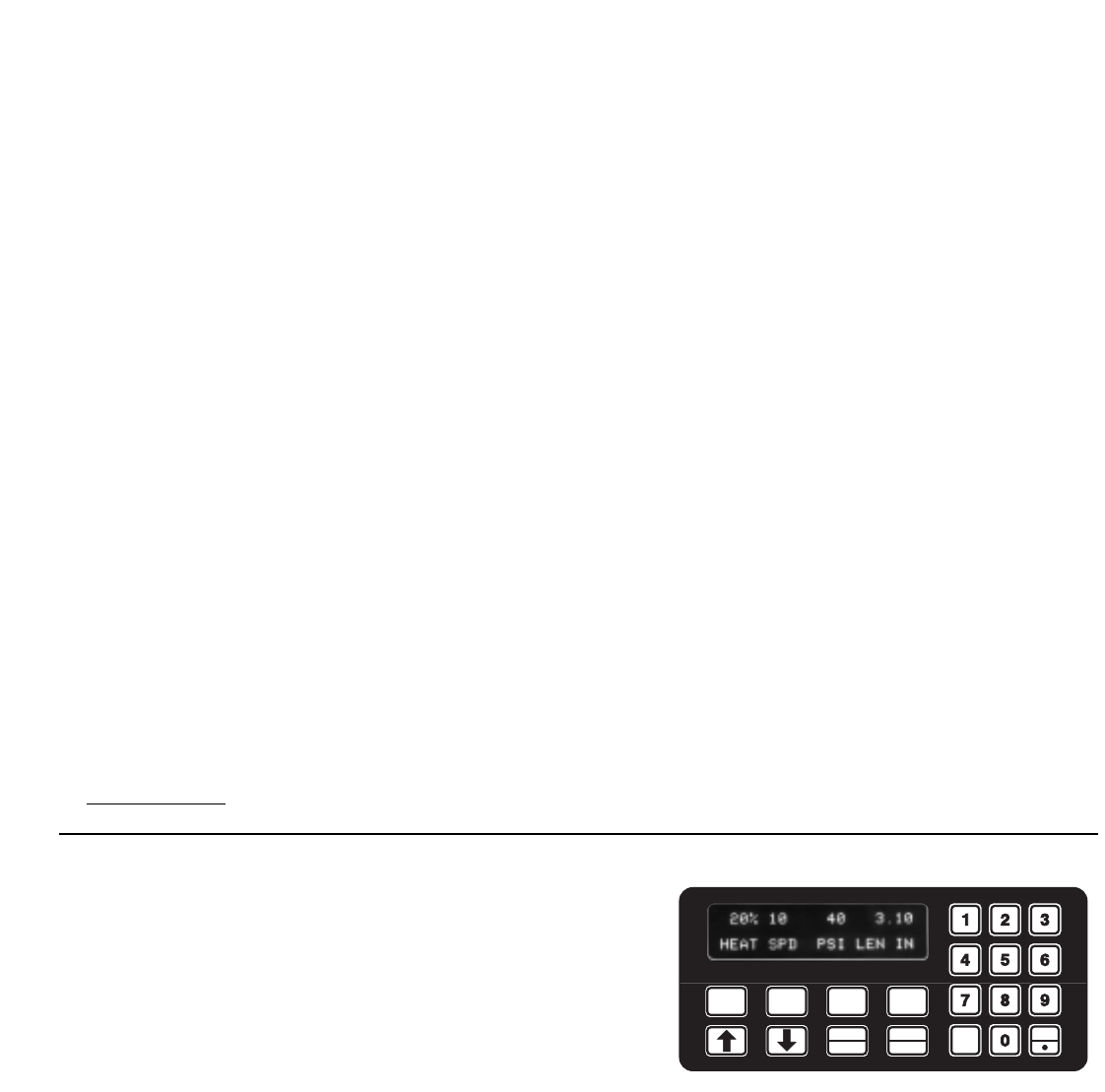

STP Operating Principles and Terms

The following section describes the basic principles of operation of the 45-930, STP.

The STP uses a combination of four variables to perform each strip. It is important to

understand each of these four control parameters and how they interrelate to obtain

the desired stripping results. The four variables are HEAT, SPEED, PRESSURE

and STRIP LENGTH. Each variable is described in terms of settings, ranges and

effects on stripping. The individual variable settings may affect the other variables

and the final stripping results. Please refer to the “Electrical Controls” section for

instructions on how to regulate each setting via the control panel.

HEAT: Thermal Blade

The HEAT setting controls the level of power (heat) directed to the blades during the thermal cutting phase of the stripping cycle, with 10% being

lowest heat and 100% highest. The STP may also be operated with a heat setting of 0%, which runs the unit through a complete cycle without using

the blades. This is intended to pull off a slug that has already been cut either by the STP or manual methods.

Since the STP is a thermal stripper, heat plays a very important role in the stripping process. Insulation materials have a wide variety of melting

temperatures, requiring the STP to produce a full range of blade HEAT settings. The melting temperature of an insulation material, high or low, must be

consistently matched by the STP blade heat setting for a successful stripping operation.

Another important factor is the rate at which the blade heat penetrates the insulation material. A tendency may be to strip at the highest blade heat avail-

able. This produces two undesirable results. First, the higher blade HEAT setting is inversely proportional to blade life. Second, the blade may

displace the insulation material too quickly, producing an excessive amount of contact with the inner shield. For these reasons it is important to

correlate the blade HEAT setting with the blade rotation SPEED setting.

STRIP

LENGTH

COUNT

CLEAR

PRESSURE

PRGM.

HIGH

SPEED

HEAT

ENTER

BATCH