25

CHAPTER 3 BEFORE USING I/O MODULE

3

3.2 Output Module

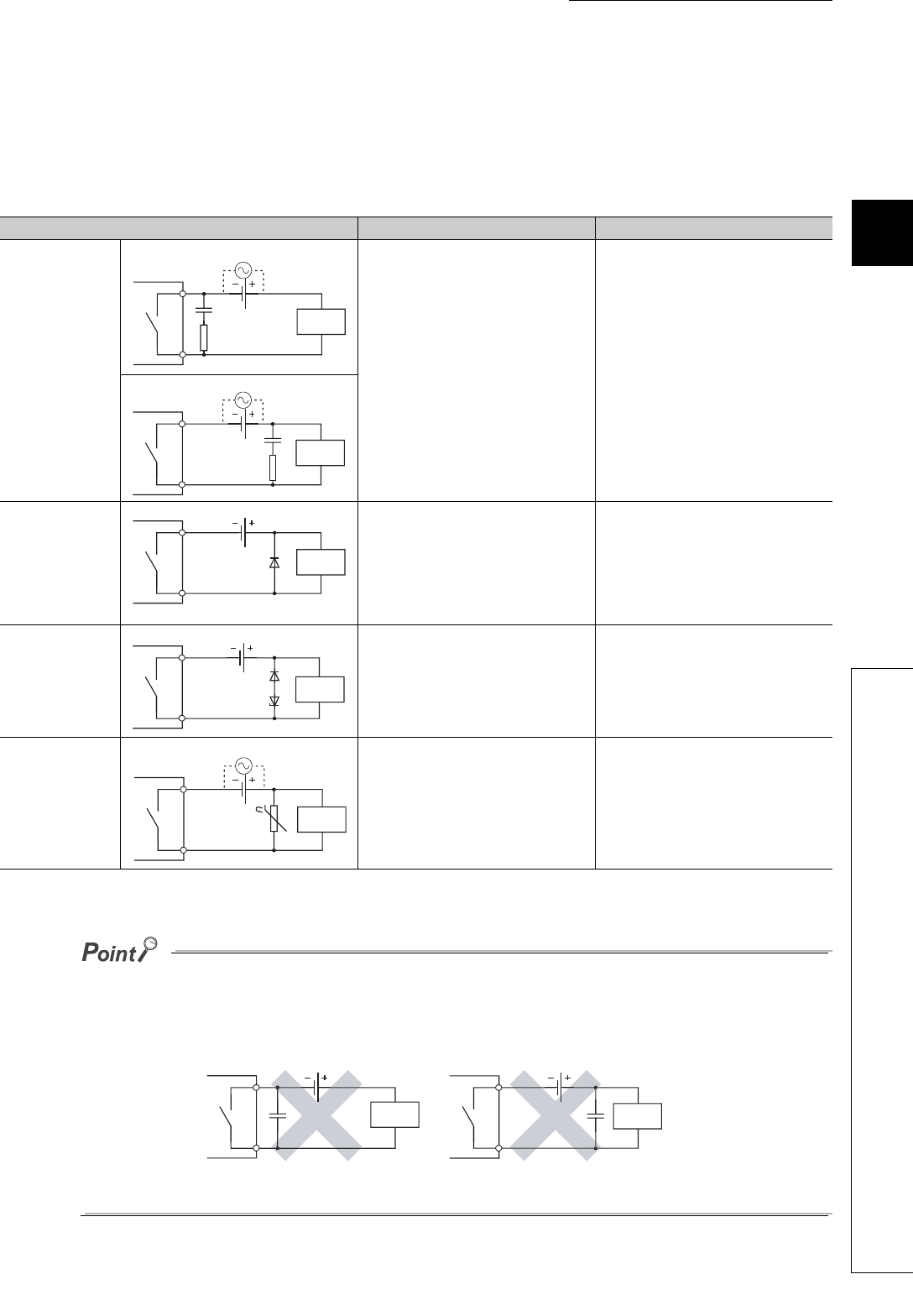

(c) Measures against back EMF

Configure a contact protection circuit for extending the contact life, preventing noise when the contact is cut off,

and suppressing the generation of carbide and nitric acid due to arc discharge.

An Incorrect contact protection circuit may cause contact welding.

Also, when using the contact protection circuit, the recovery time may be long.

The following table shows the representative examples of the contact protection circuit.

*1 When using AC power, impedance of CR must be larger enough than it of the load (prevention of a malfunction due to

leak current from the CR).

● Avoid providing a contact protection circuits shown below.

These circuit are effective for preventing an arc at shut-off. However, the contact welding may occur because the charge

current flows to capacitor when the contact turns on or off.

A DC inductive load is usually harder for switching than a resistor load, but if a proper protection circuit is configured, the

performance will be similar to the resistor load.

● A protection circuit must be provided closely to a load or contact (module). If their distance is far, the protection circuit

may not be effective. Appropriate distance is within 50 cm.

Example Method for selecting elements Remarks

Capacitor + Resistor

method (CR

method)

Refer to the following for constants of the

capacitor and resistor. Note that the

following values may differ depending on a

nature of the load and a variation of

characteristics of it.

• Capacitor: 0.5 to 1(µF) against load

current of 1A

• Resistor: 0.5 to 1() against power

supply voltage of 1V

Use a capacitor whose withstand voltage is

equal to or more than the rated voltage. In

AC circuit, use a capacitor having no

polarity.

If a load is a relay or solenoid, the recovery

time delays.

A capacitor suppresses electric discharge

while a contact is off, and a resistor

restricts a flow of current while a contact is

on.

Diode method

Use a diode that meets both conditions

shown below.

• Reverse breakdown voltage is equal to

or more than 10 times as large as the

circuit voltage.

• The forward current is equal to or more

than 2 times as large as the load current.

The recovery time is slower than the CR

method.

Diode + Zener diode

method

Use zener voltage for the zener diode

equal to or more than the power supply

voltage.

This method is effective when the recovery

time delays considerably by the diode

method.

Varistor method

Select a cut voltage (Vc) for the varistor to

meet the following condition.

• Vc > Power voltage × 1.5(V)

• Vc > Power supply voltage × 1.5(V) × √2

(when using AC power supply)

This method is not effective when the Vc is

too high

The recovery time delays slightly.

*1

Capacitor

Resistor

Inductive

load

Capacitor

Resistor

Inductive

load

Diode

Inductive

load

Diode

Inductive

load

Zener Diode

Varistor

Inductive

load

Capacitor

Inductive

load

Capacitor

Inductive

load