18

E-AC Drive Hardware Installation Guide Chapter 2 – Installation

2 – CONNECT THE MOTOR TO THE DRIVE – WIRING

Most Compumotor motor windings—phase A and phase B—are bifilar

windings made from double-stranded copper wire. Each phase has two

half-windings, which can be wired together in series or parallel.

These two alternatives—series and parallel—produce different speed/

torque characteristics, affect the motor’s current rating, and alter the

motor’s operating temperature. They are explained below.

GROUND THE MOTOR CASE

The motor case must be grounded, for safety purposes. On pre-cabled

Compumotor motors, one end of the cable shield is permanently wired to

the motor case; you should connect the other end to on the drive’s

motor connector. Inside the drive, connects directly to the ground pin

on the AC power terminals.

PRECAUTIONS

Follow these precautions when you wire the motor connector.

1. Turn off power to the drive before connecting or disconnecting the motor

leads.

2. Verify that no wire whiskers short out motor connections.

3. Do not apply power to the drive when the motor is not connected.

4. Never connect anything other than the motor to the motor terminals.

5. After wiring the motor connector, perform the Automatic Test, to verify that

the connector is wired correctly.

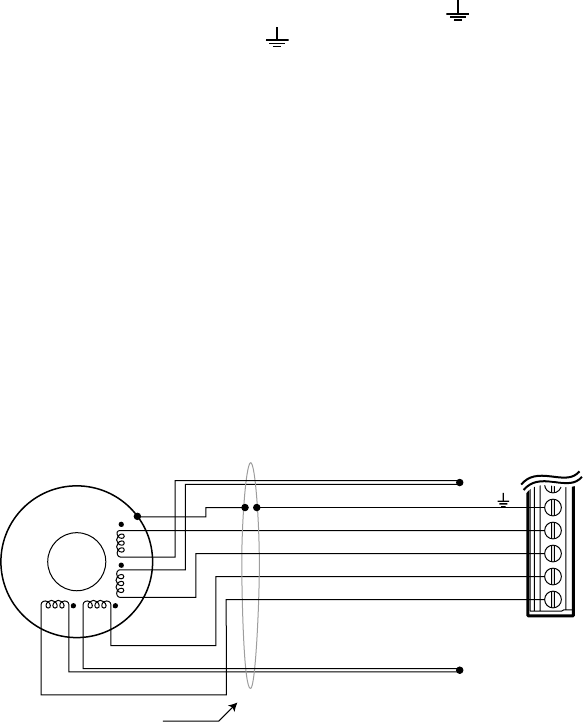

CONNECTING THE MOTOR: SERIES WIRING

For series motor current, connect a Compumotor motor as shown in the

following diagram.

A +

A -

B +

B -

Compumotor Motor

Shield is internally connected

to the motor’s case

PM

Phase A

Windings

Phase B

Windings

Shield

Red

Black

White

Green

Orange

Brown

Yellow

Blue

OS Motors;

VS Motors

(with cable):

Red

Yellow

Orange

Black

Orange/White

Black/White

Red/White

Yellow/White

VS Motors

(flying lead):

Motor Connector – Wired for SERIES Motor Current

Be sure to insulate the center tap connections; these are the wires shown

joined together in the drawing above, but not connected to the drive.

The operating temperature of a motor connected in series will be lower

than that of a motor connected in parallel. Therefore, you should operate

your motor in series, if your application permits. Typically, series connec-

tions work well in high torque/low speed applications.