14-6 Chapter 14 Maintenance and Inspection

Chapter 14

Maintenance and Inspection

14-5 Regular Checks

14-5-2 Maintenance Timings

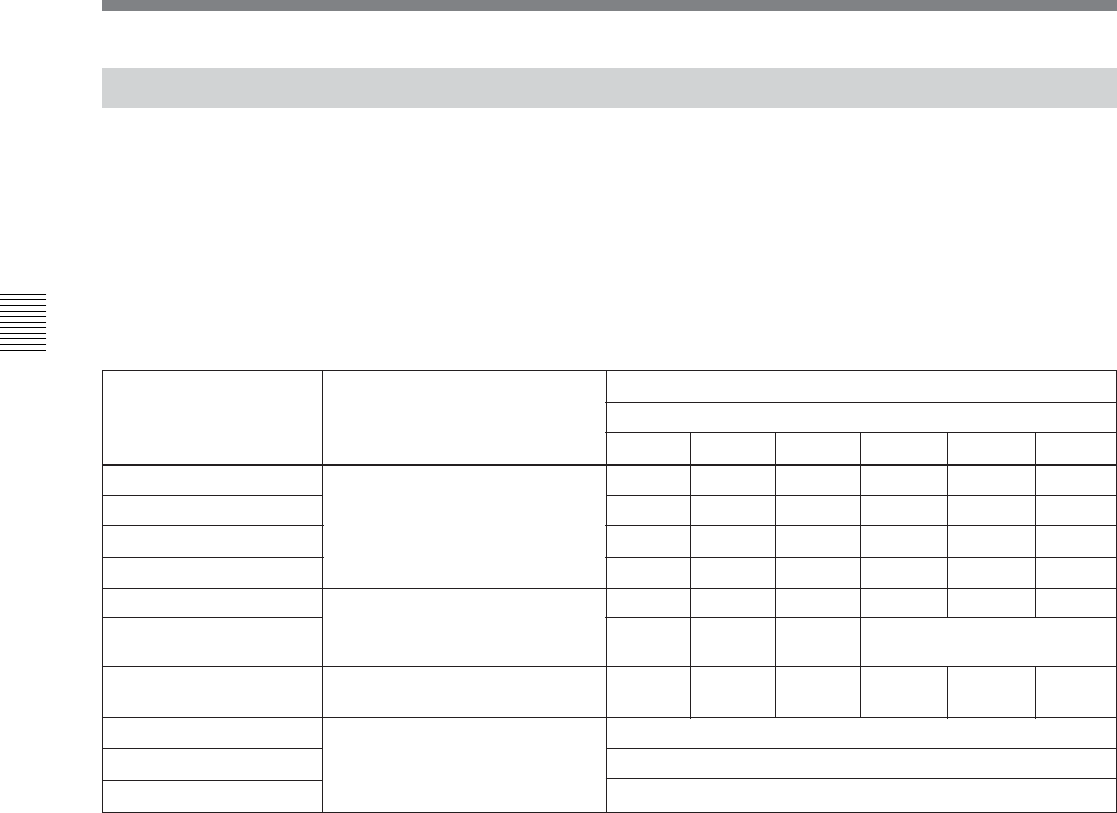

Use the following table as a timing guide for checking

and replacing components of the unit.

These intervals are not guaranteed lifetimes; the timing

for replacing components depends on the particular

conditions of use. In particular, depending on the

degree of dirt contamination and abrasion, pinch

rollers and cleaners may require replacement earlier

than suggested by this table.

Note that an arrow in the table means that the

component to be replaced is part of the assembly the

arrow points to, which must be replaced as a whole.

For information on severe conditions (frequent threading/

unthreading) or how to replace components, refer to the

Maintenance Manual Volume 1.

Component

Digital hours meter indication

(menu number in parenthesis)

Guideline replacement intervals

R: Replace C: Check, and replace if necessary

1000 hrs 2000 hrs 3000 hrs 4000 hrs 5000 hrs 6000 hrs

Upper drum

Drum running time (H02)

Drum assembly

Brush slip ring assembly

Video head cleaner (roller)

Pinch roller assembly

Tape running time (H03)

Reel table assembly

Pinch application

assembly

Tape running time (H03)

Fan motor (card)

Operation time (H01) Replace after 40,000 hours

Fan motor (MD)

Replace after 40,000 hours

Power supply unit Replace after 40,000 hours

CCCC(↓)

C

RR(↑)

RR

RR

R (Replace at interval of

4000 hours.)

R