130

FX3S Series Programmable Controllers

User's Manual - Hardware Edition

14 Test Operation, Adjustment, Maintenance and Troubleshooting

14.3 Operation and Test [Power ON and PLC Running]

14.3 Operation and Test [Power ON and PLC Running]

14.3.1 Self-diagnostic function

When the PLC’s power is turned on, its self-diagnostic function starts automatically. If there are no problems

with the hardware, parameters or program, the PLC will start and the RUN command (refer to Section 14.2) is

given (RUN LED is lit). If any problems are found, the "ERR" LED flashes or lights.

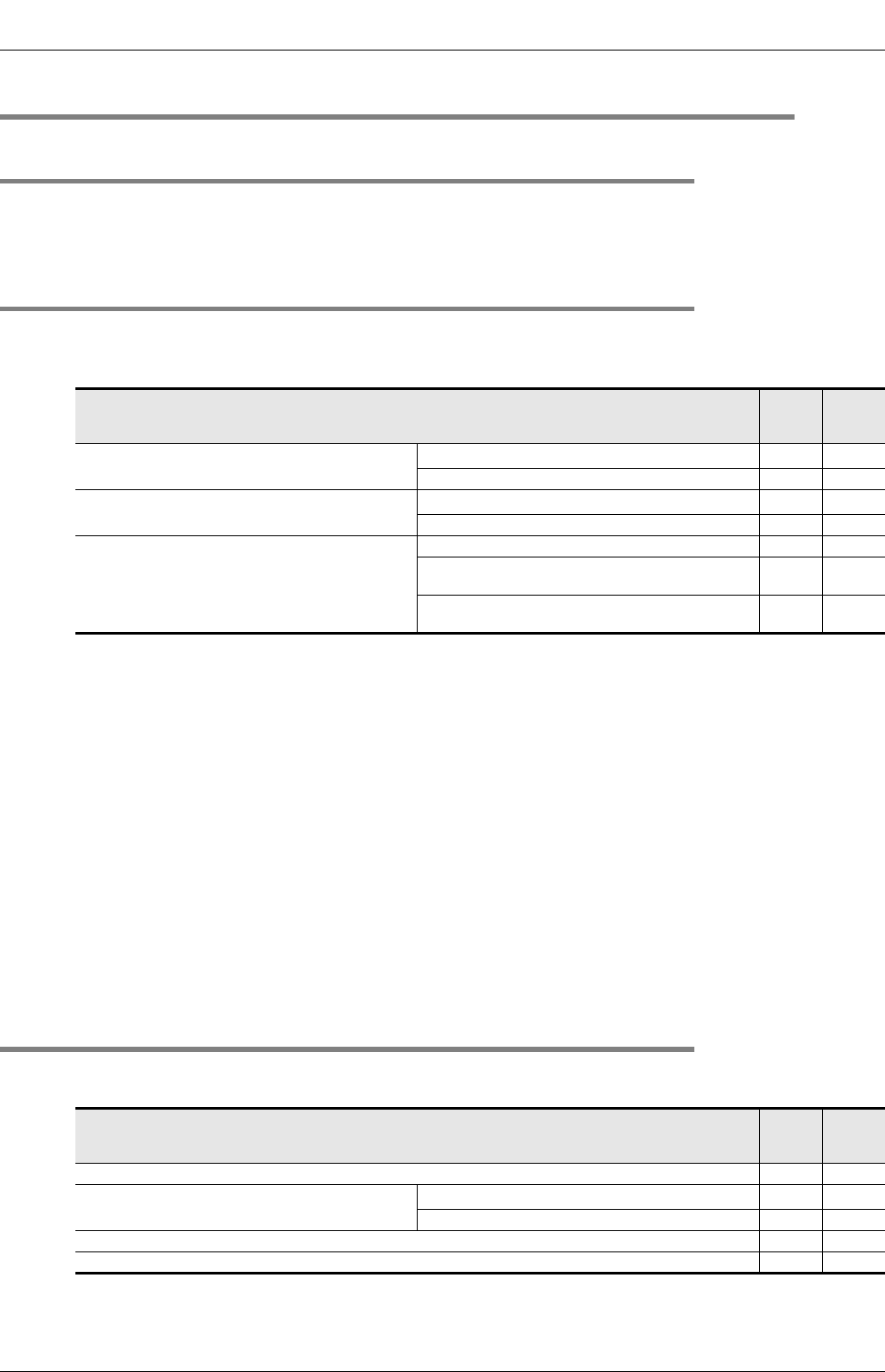

14.3.2 Test functions

Functions of the programming tool to turn on/off the PLC devices and change the current values/settings are

effective or ineffective depending on the PLC status as shown below.

: Effective : Conditionally effective -: Ineffective

*1. Forcible ON/OFF

- The forcible ON/OFF function is effective on the input relays (X), output relays (Y), auxiliary relays (M), state (S),

timers (T) and counters (C).

- The forcible ON/OFF function can turn on or off the devices only for one scan.

While the PLC is running, the function is substantially effective in clearing the current values of the timers (T),

counters (C), data registers (D), index registers (Z and V) and in controlling the SET/RST circuit and self-retaining

circuit. (The operation to forcibly turn on timers is effective only when the timers are driven by the program.)

- The results of forcible ON/OFF operation performed while the PLC in the stopped state or performed for devices not

used in the program are retained.

However, the results of the operation performed for the input relays (X) are not retained because the relays refresh

input even while the PLC is in the stopped state. (They are updated according to the input terminal conditions.)

*2. Since the current values may be changed according to MOV instruction in the program and the

operation results, the most recently obtained values are retained.

*3. The current values of the file registers stored in the program memory cannot be monitored or tested

on the display module.

*4. Change of timer and counter settings. The settings of the timers (T) and counters (C) can be changed

only when the timers are driven by the program.

14.3.3 Program modification function

The sequence program can be transferred while the PLC is running or in the stopped state as shown below.

: Effective -: Ineffective

*1. Since the writing function is used during running, the programming tool must support the write during

RUN function, such as GX Works2.

For the writing function during running, refer to Subsection 5.2.5.

Item

In

running

status

In

stopped

status

Forcible ON/OFF

*1

Devices used in program

*1

*1

Devices not in use

Change of current values of timers, counters, data

registers and file registers

*3

Devices used in program

*2

Devices not in use

Change of settings of timers and counters

*4

When the program memory is the built-in EEPROM

When the program memory is in the memory cassette

and the PROTECT switch is on

--

When the program memory is in the memory cassette

and the PROTECT switch is off

Item

In

running

status

In

stopped

status

Batch writing of file registers (D) -

Writing of program to PLC

Partial modification of program

*1

Modification of whole program (batch writing) -

Writing of parameters to PLC -

Writing of comments to PLC -