137

FX3S Series Programmable Controllers

User's Manual - Hardware Edition

11

Built-in Analog

12

Output Wiring

13

Wiring for

Various Uses

14

Test Run,

Maintenance,

Troubleshooting

15

Other Extension

Units and

Options

16

Display Module

(FX

3S

-5DM)

17

Memory

Cassette

A

Special Devices

(M8000-, D8000-)

B

Instruction List

C

Discontinued

models

14 Test Operation, Adjustment, Maintenance and Troubleshooting

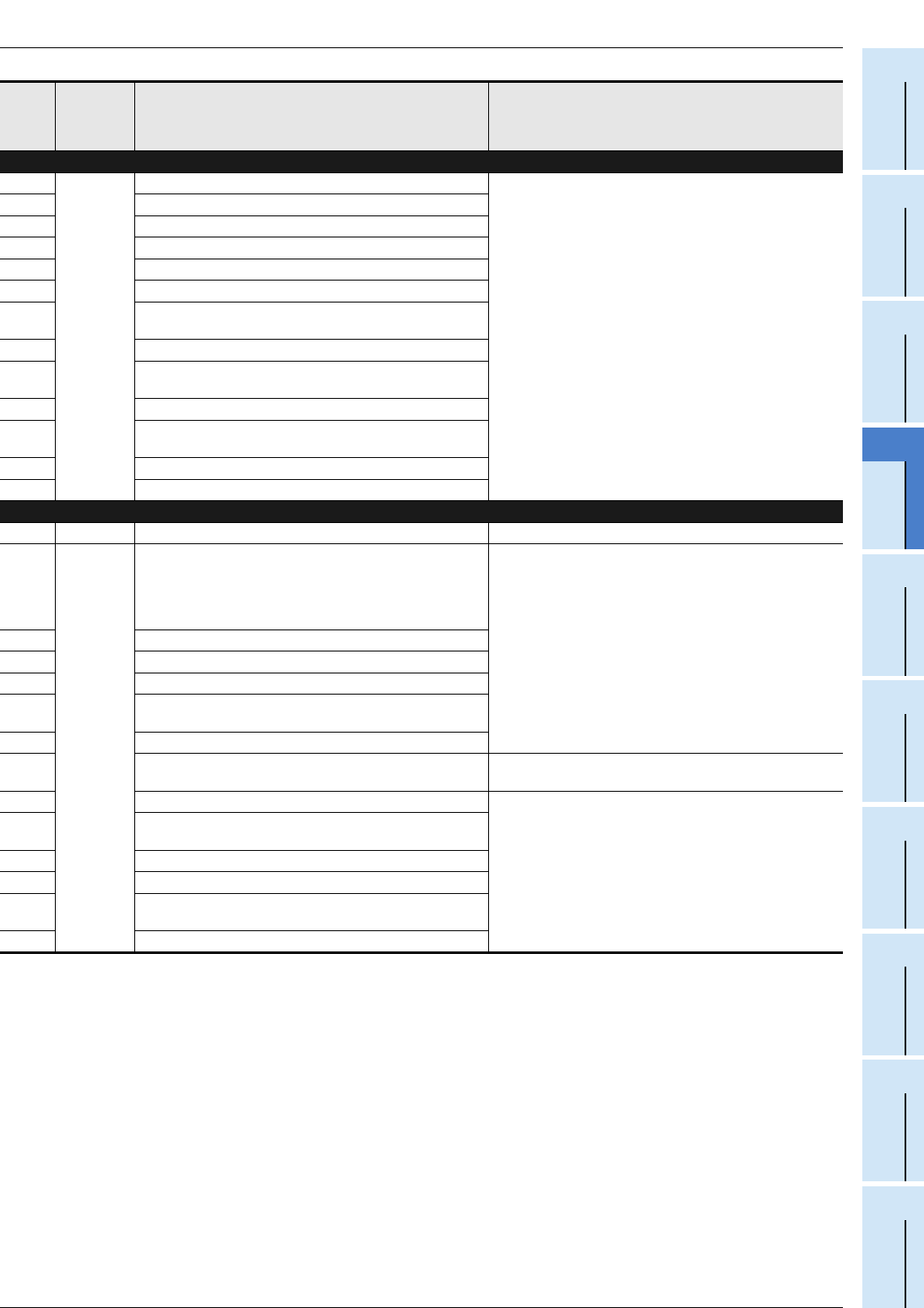

14.6 Judgment by Error Codes and Representation of Error Codes

Circuit error [M8066 (D8066)]

6620

Stops

operation

FOR-NEXT instruction nesting level exceeded

This error occurs when a combination of instructions is

incorrect in the entire circuit block or when the relationship

between a pair of instructions is incorrect.

Modify the instructions in the program mode so that their

mutual relationship becomes correct.

6621 Numbers of FOR and NEXT instructions do not match.

6622 No NEXT instruction

6623 No MC instruction

6624 No MCR instruction

6625 STL instruction is continuously used 9 times or more.

6626

Invalid instruction is programmed within STL-RET loop:

MC, MCR, I (interrupt pointer), SRET or IRET.

6627 No STL instruction

6628

Invalid instruction is used in main program:

I (interrupt pointer), SRET or IRET

6629 No P or I (interrupt pointer)

6630

No SRET or IRET instruction

STL-RET or MC-MCR instructions in subroutine

6631 SRET programmed in invalid location

6632 FEND programmed in invalid location

Operation error [M8067 (D8067)]

0000 - No error

6701

Continues

operation

• No jump destination (pointer) for CJ or CALL instruction

• Label is undefined or out of P0 to P255 due to indexing.

• Label P63 is executed in CALL instruction; cannot be used

in CALL instruction as P63 is for jumping to END

instruction.

This error occurs in the execution of operation. Review the

program and check the contents of the operands used in

applied instructions.

Even if the syntax or circuit design is correct, an operation

error may still occur.

For example:

"T100Z" itself is not an error. But if Z had a value of 100, the

timer T200 would attempt to be accessed. This would cause

an operation error since there is no T200 device available.

6702 CALL instruction nesting level is 6 or more

6704 FOR-NEXT instruction nesting level is 6 or more.

6705 Operand of applied instruction is inapplicable device.

6706

Device number range or data value for operand of applied

instruction exceeds limit.

6709 Other (e.g. improper branching)

6710 Mismatch among parameters

This error occurs when the same device is used within the

source and destination in a shift instruction, etc.

6730 Incorrect sampling time (T

S) (TS 0)

<PID instruction is stopped.>

This error occurs in the parameter setting value or operation

data executing PID instruction.

Check the contents of the parameters.

6732

Incompatible input filter constant ()

( < 0 or 100 )

6733 Incompatible proportional gain (K

P) (KP < 0)

6734 Incompatible integral time (T

I) (TI < 0)

6735

Incompatible derivative gain (K

D)

(K

D < 0 or 201 KD)

6736 Incompatible derivative time (T

D) (TD < 0)

Error

code

PLC

operation

at error

occurrence

Contents of error Action