PAGE 18 —V304 VIBRATORY ROLLER — OPERATION AND PARTS MANUAL — REV. #8 (11/13/09)

V304 — GENERAL INFORMATION

The V304 Vibratory Roller is a walk-behind vibratory roller

specifically designed for the compaction and patching of asphalt

type surfaces.

The compaction force is delivered by a 30-inch wide steel drum

with beveled edges to help prevent asphalt

marring

. A fully

enclosed hydrostatic drive system offers a variable speed control

as well as smooth acceleration and braking

HYDROSTATIC DRIVE SYSTEM

This hydrostatic design offers a smooth performance, because

of a fully integrated hydrostatically actuated drive system, which

provides a variable speed control under varying load conditions.

Power from the hydraulic drive system is transferred via a drive

belt to a gear reducer.

CONTROLS

The forward-reverse control lever (located on the handle)

operates the hydrostatic pump which governs the roller speed

and direction of travel. The neutral position of this lever will cause

the roller to stop. The vibration control when actuated will apply

a force of 4,400 vpm (vibrations per minute). This vibratory feature

is controlled by an eccentric shaft via an operator controlled

mechanical clutch.

FREE WHEEL ENGAGEMENT LEVER

The hydrostatic transmission is equipped with a free wheel

engagement lever, which, when actuated, allows the oil to circulate

freely within the roller, thereby permitting the roller to be moved

without the engine running. This lever is only to be used in the

event the roller is disabled.

This lever is located on the that side of the transmission which

faces the front of the roller. It is actuated by placing the handle

into the side-lock position. To gain access to this lever raise the

roller's hood. DO NOT raise hood while engine is running, STOP

engine.

.

NOTE

In normal operating conditions the roller

will not move in a forward or reverse

direction unless the free wheel

engagement lever is in the engage position

(forward).

SPRINKLER SYSTEM

A 8.3 gallon (31.4 liters) water tank with a gravity feed spray bar

is provided for wetting the roll for asphaltic pavement rolling.

Before starting an asphalt rolling job, be sure all spray bar holes

are clear of dirt or foreign matter and are working. A coco mat is

provided to insure an even distribution of water.

DO NOT leave the coco mat in contact with the roll (drum) when

the roller is used for earth compaction. A hook is provided to hold

the mat away from the roll. The coco mats are intended to prevent

the build-up of material between the drum and the frame.

Always use clean fresh water in the water tank. To prevent rust

and foreign debris from clogging the spray bar holes, drain and

flush water tank and spray bars every 30 days.

TRANSPORTATION

To help transport the roller from job site to job site, adjustable

transport hooks have been provided. These transport hooks allow

an operator to place the roller on the tailgate of a dump truck

without any assistance. The control handle of the V304 roller

can be folded vertically for ease of transport and storage.

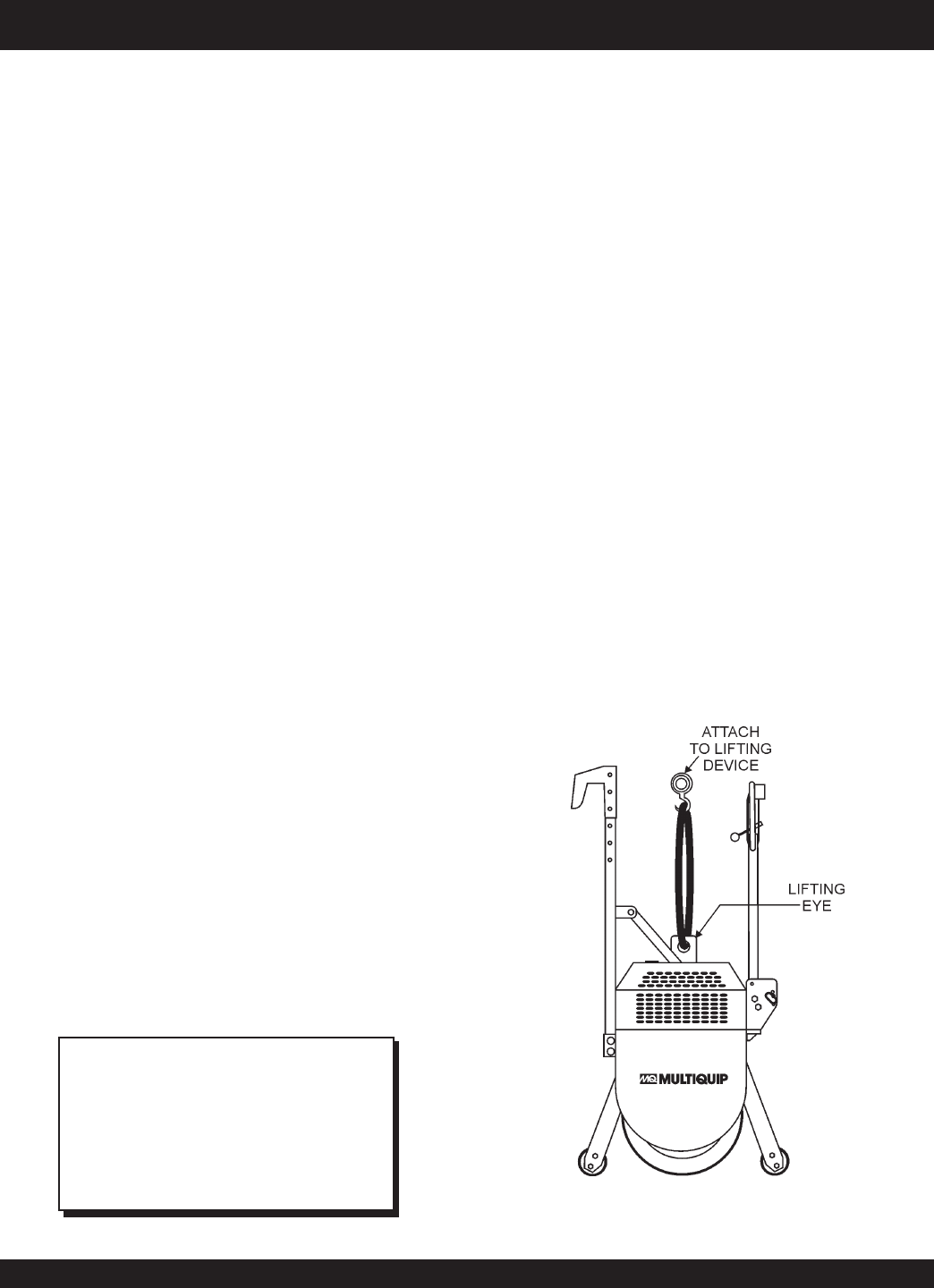

LIFTING THE ROLLER

When lifting of the roller is required (Figure 7), attach a suitable

hook or shackle to the

lifting eye

of the roller. Make sure the

lifting device is capable of lifting 1,045 lbs (450 kg).

Figure 7. Lifting The Roller