T775U SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLER

62-0255—09 4

Use a screwdriver to pry out only the knockouts that you

will use.

If mounting on DIN rail, be sure to remove the knockouts

before mounting. See “Controller Wiring” on page 7 and

Fig. 12 on page 9 for recommended knockout usage and

locations. If you do not use an opened knockout be sure

to cover it.

Mount the controller on any convenient interior location

using the four mounting holes provided on the back of the

enclosure using #6 or #8 screws (screws are not provided

and must be obtained separately). Use controller

dimensions in Fig. 1 on page 3 as a guide.

The controller may be mounted in any orientation.

However, mounting in the orientation shown in Fig. 1 on

page 3 permits proper viewing of the LCD display and use

of the keypad.

Humidity, Pressure, and Universal

Sensor(s) Mounting and Location

These sensors may be mounted on a wall or panel. Follow

the installation instructions specific to the sensor you are

installing.

Temperature Sensor(s) Mounting

and Location

Temperature sensors may be located up to 1,000 feet

(304 m) from the T775U controller. See Table 4 on

page 11 for calibration guidelines.

The sensors may be mounted on a wall or panel for

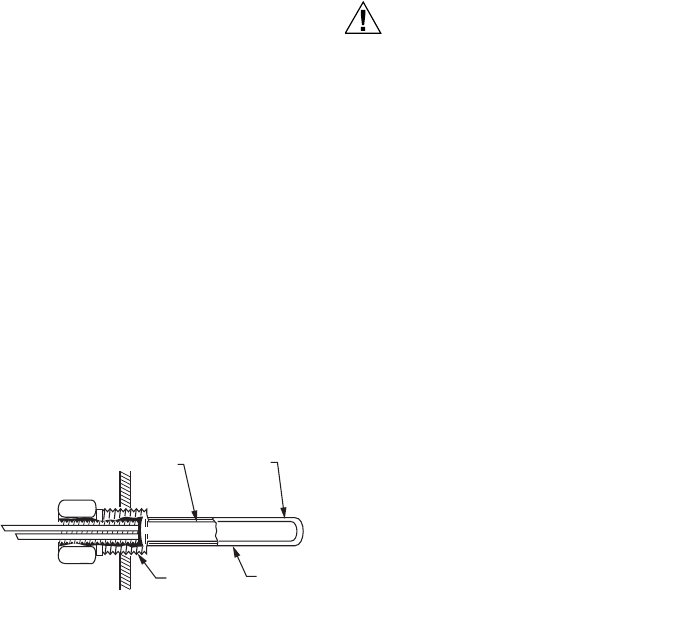

sensing space temperature, strapped to a pipe or inserted

in an immersion well (see Fig. 2) for hot or cold water

sensing, or taped to a standard cap or bulb holder for duct

air sensing. To prevent moisture or condensation entering

the sensor through the lead wire holes, mount the sensor

with the lead wires exiting the bottom of the sensor.

NOTES:

1. The included sensor is not designed for very

wet applications. For immersion applications,

an immersion well is used.

2. Heat conductive compound must be used in

immersion wells.

3. See “Temperature Sensors (Sensor A or B)”

on page 2 for this type of installation.

Fig. 2. Sensor inserted in immersion well.

NOTE: Multiple sensors may be parallel-series wired

to sense average temperatures in large

spaces. See Fig. 3 on page 5.

WIRING

All wiring must comply with applicable electrical codes

and ordinances, or as specified on installation wiring

diagrams. Controller wiring is terminated to the screw

terminal blocks located inside the device.

The remainder of this section describes the sensor wiring

and the T775U controller wiring.

Wiring Connections Access

To access the wiring connections, remove the two screws

on the left side of the enclosure and gently swing open the

top. Be careful to not stress the ribbon cables that connect

the keypad and LCD display to the controller circuit board.

Temperature Sensor Wiring

CAUTION

Electrical Shock Hazard.

Can short equipment circuitry.

Make sure that metal tube of sensor does not

short against T terminals in wall-mounted case.

IMPORTANT

Poor wiring practices can cause erratic readings

from the sensor. Avoid the following to ensure

proper operation:

• Do not route the temperature sensor wiring with

building power wiring.

• Do not locate the temperature sensor wiring next

to control contactors.

• Do not locate the temperature sensor wiring near

electrical motors.

• Do not locate the temperature sensor wiring near

welding equipment.

• Make sure good mechanical connections are

made to both the sensor and the controller.

• Do not mount the sensor with the lead wire end

pointing up in an area where condensation can

occur.

If any of the above conditions cannot be avoided,

use shielded cable.

NOTE: Each T775 controller must be wired to its own

sensor(s). However, a benefit of the T775

controller’s accuracy is that there is no more

than a 2°F differential between any two T775

controllers.

Reset Temperature Control

If you are implementing two-sensor reset control, Sensor

A must always be the controlled temperature and Sensor

B must always be the controlling temperature.

For example, in a reset control based on outside

temperature, Sensor A must be the inside sensor and

Sensor B must be the outside sensor.

Multiple Parallel Temperature Sensors

Multiple sensors can be parallel-series wired to sense

average temperatures in large spaces. To maintain control

accuracy, the number of sensors to be parallel-series

wired must be of the n

2

power (for example, 4, 9, 16, etc.).

See Fig. 3.

SENSOR

PLACED

IN WELL

IMMERSION

WELL

1/2 NPT

USE HEAT

CONDUCTIVE

COMPOUND

M24379