FX Series Programmable Controlers Applied Instructions 5

5-102

5.9.8 PID (FNC 88)

Operation:

This instruction takes a current value (S

2

) and

compares it to a predefined set value (S

1

). The

difference or error between the two values is then

processed throu

g

h a PID loop to produce a

correction factor which also takes into account previous iterations and trends of the calculated

error. The PID process calculates a correction factor which is applied to the current output

value and stored as a corrected output value in destination device (D). The setup parameters

for the PID control loop are stored in 25 consecutive data re

g

isters S

3

+0 throu

g

h S

3

+24.

Points to note:

a) Ever

y

PID application is different. There will be a certain amount of “trial and error”

necessar

y

to set the variables at optimal levels.

b) The PID instruction is

only

available on FX and FX

2C

Main Processin

g

Units fitted with

CPU

versions 3.11 or greater

.

c) On FX

2N

MPUs a Pre-tunin

g

feature is available that can quickl

y

provide initial values for the

PID process. Refer to pa

g

e 10-28 for more details.

d) As 25 data re

g

ister are required for the setup parameters for the PID loop, the head address

of this data stack cannot be

g

reater than D975. The contents of this data stack are

explained later in this section. Multiple PID instructions can be pro

g

rammed, however

each PID loop must not have conflictin

g

data re

g

isters.

e) There are control limits in the PLC intended to help the PID controlled machines operate in

a safe manner. If it becomes necessar

y

to reset the Set Point Value (S

1

) durin

g

operation,

it is recommended to turn the PID command Off and restore the command after enterin

g

the

new Set Point Value. This will prevent the safet

y

control limits from stoppin

g

the operation

of the PID instruction prematurel

y

.

f) The PID instruction has a special set of error codes associated with it. Errors are identified

in the normal manner. The error codes associated with the PID loop will be fla

gg

ed b

y

M8067 with the appropriate error code bein

g

stored in D8067. These error devices are not

exclusive to the PID instruction so care should be taken to investi

g

ate errors properl

y

.

Please see chapter 6, ‘Dia

g

nostic Devices’ for more information.

g

) A full PID iteration does not have to be performed. B

y

manipulation of the setup parameters

P (proportional), I (Inte

g

ral) or D (derivative) loops ma

y

be accessed individuall

y

or in a user

defined/selected

g

roup. This is detailed later in this section.

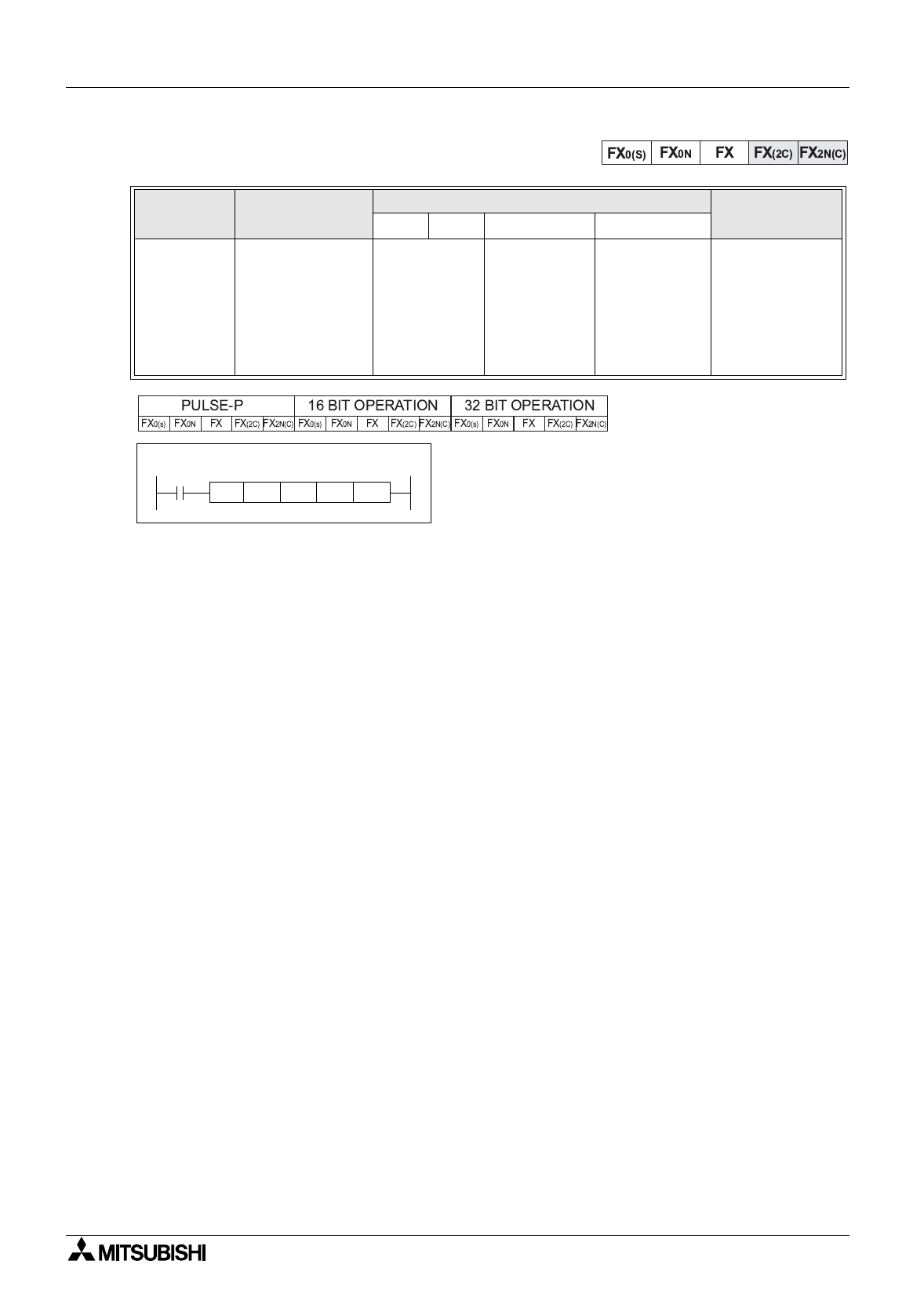

Mnemonic Function

Operands

Program steps

S

1

S

2

S

3

D

PID

FNC 88

(PID

control loop)

re

g

ister each

Receives a data

input and

calculates a

corrective action

to a specified

level based on

PID control

D

Note: S

1

and S

2

use a sin

g

le

data re

g

ister

D

Note: S

3

uses 25

consecutive

data re

g

isters

D

Note: D

uses a sin

g

le

data re

g

ister

PID:

9 steps

X10

D 19D18PID

[ S1 ] [ S2 ] [ D ]

D 20 D 46

[ S3 ]