Teledyne API T703/T703U Calibrator Operation Manual Principles of Operation

217

The critical flow orifice installed in the pump supply line is tuned to create a gas flow of

800 cm

3

/min. A pressure sensor and a flow sensor, located on the O

3

generator /

photometer pressure flow sensor PCA, monitor the pressure and flow rate of the gas

passing through the photometers absorption tube.

See Figure 9-18 through Figure 9-22 for depictions of the gas flow related to the

photometer.

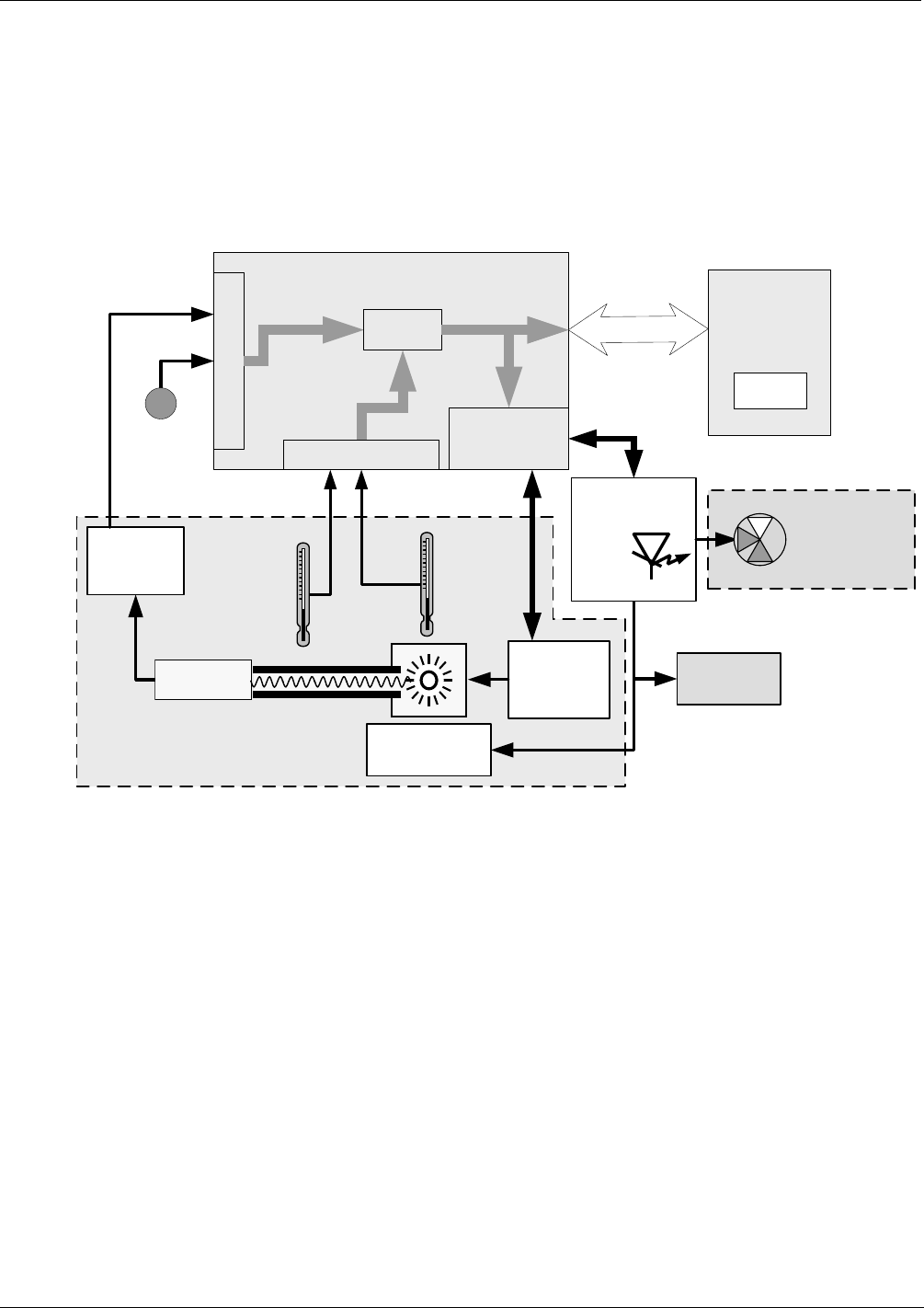

9.6.4. PHOTOMETER ELECTRONIC OPERATION

Photometer

Photometer

Lamp Heater

Motherboard

Photometer

Lamp Power

Supply

Sensor Inputs

P

C

1

0

4

B

u

s

I

2

C Bus

Photometer

Pump

Thermistor Interface

Photometer

Detector

Preamp

A/D

Converter

RELAY PCA

I

2

C

Status

LED

y

PC 104

CPU Card

Disk on

Module

Absorption tube

Photometer

Detector

Photometer

Sample Gas

Pressure

Sensor

Photometer

UV Lamp

Temperature

Photometer

Sample Gas

Temperature

Photometer M/R

Valve

(Located on O

3

Generator Assembly)

Figure 9-24: O

3

Photometer Electronic Block Diagram

Like the O

3

generator, the O

3

photometer and its subcomponents act as peripheral

devices operated by the CPU via the motherboard. Communications to and from the

CPU are handled by the motherboard.

Outgoing commands for the various devices such as the photometer pump, the UV lamp

power supply the U\V Lamp heater are issued via the I

2

C bus to circuitry on the relay

PCA which turns them ON/OFF. The CPU also issues commands over the I

2

C bus that

cause the relay PCA to cycle the measure/reference valve back and forth.

Incoming date the UV light detector is amplified locally then converted to digital

information by the motherboard. Output from the photometers temperature sensors is

also amplified and converted to digital data by the motherboard. The O

3

concentration

of the sample gas is computed by the CPU using this data (along with gas pressure and

flow data received from the pressure sensors.

07223C DCN6572