139

FX3S Series Programmable Controllers

User's Manual - Hardware Edition

11

Built-in Analog

12

Output Wiring

13

Wiring for

Various Uses

14

Test Run,

Maintenance,

Troubleshooting

15

Other Extension

Units and

Options

16

Display Module

(FX

3S

-5DM)

17

Memory

Cassette

A

Special Devices

(M8000-, D8000-)

B

Instruction List

C

Discontinued

models

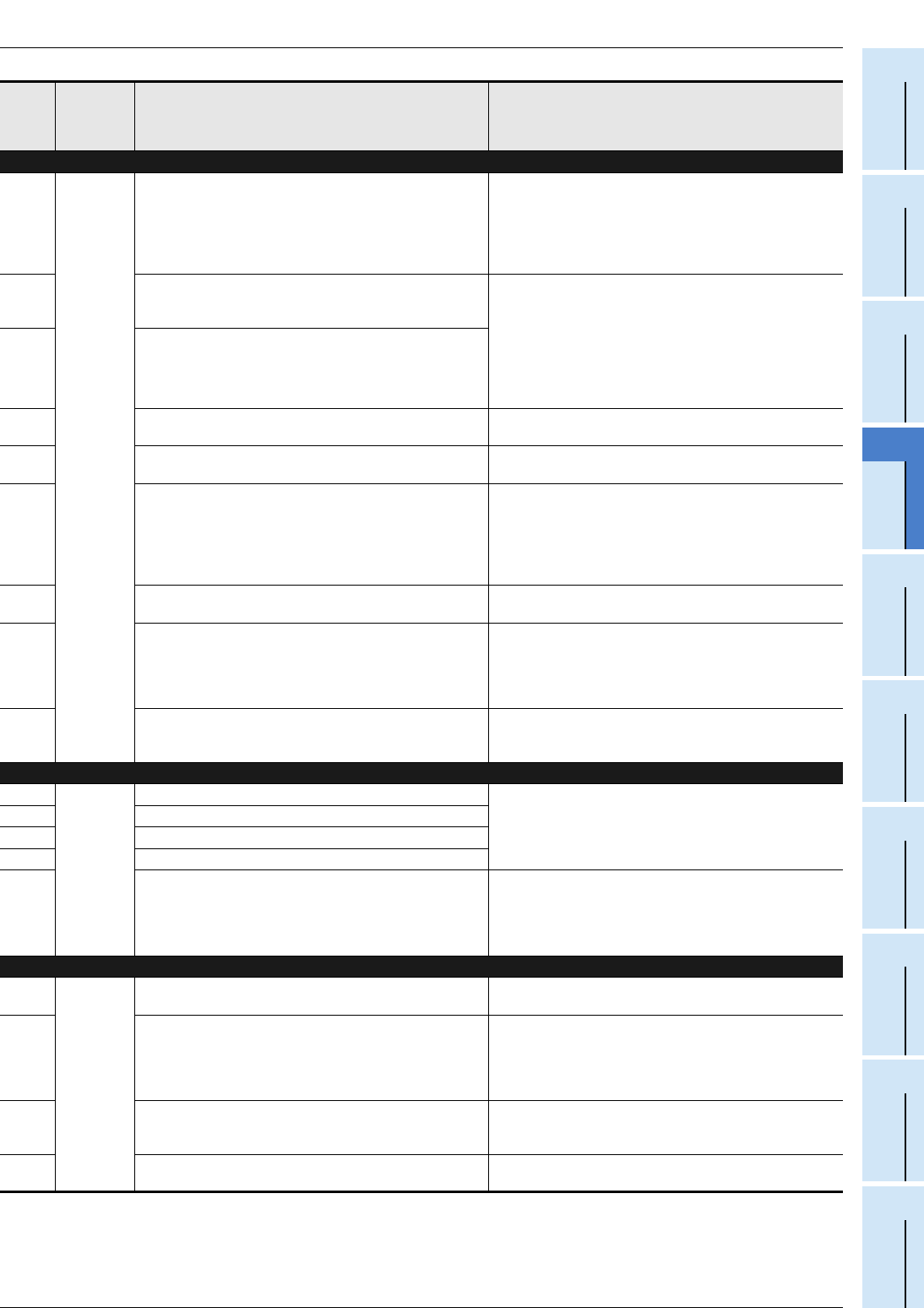

14 Test Operation, Adjustment, Maintenance and Troubleshooting

14.6 Judgment by Error Codes and Representation of Error Codes

Operation error [M8067 (D8067)]

6757

Continues

operation

<Limit cycle method>

Auto tuning result exceeds proportional gain. (KP = outside

range from 0 to 32767)

<Auto tuning is finished (KP = 32767). PID operation is

started.>

The variation of the measured value (PV) is small compared

with the output value. Multiply the measured value (PV) by

"10" so that the variation of the measured value will increase

during auto tuning.

6758

<Limit cycle method>

Auto tuning result exceeds integral time.

(TI = outside range from 0 to 32767)

<Auto tuning is finished (KP = 32767). PID operation is

started.>

The auto tuning time is longer than necessary.

Increase the difference (ULV - LLV) between the upper limit

and lower limit of the output value for auto tuning, set a

smaller value to the input filter constant (), or set a smaller

value to the PV threshold (SHPV) for auto tuning, and then

check the result for improvement.

6759

<Limit cycle method>

Auto tuning result exceeds derivative time.

(TD = outside range from 0 to 32767)

6760 ABS data read from servo sum check error

Check servo wiring and parameter setting. Also check ABS

instruction.

6762

Port specified by inverter communication instruction is already

used in another communication.

Check to make sure the port is not specified by another

instruction.

6763

Input (X) specified by DSZR or ZRN instruction is already

used in another instruction.

Check to make sure the input (X), as specified by DSZR or

ZRN instruction, is not being used for the following purposes:

- Input interrupt

- High-speed counter C235 to C255

- Pulse catch M8170 to M8175

- SPD instruction

6764

Pulse output number is already used in a positioning

instruction or pulse output instruction (PLSY, PWM, etc.).

Check to make sure the pulse output destination is not being

driven by another positioning instruction.

6770 Memory access error

When the memory cassette is used, check whether it is

mounted correctly.

If the problem persists or if the memory cassette is not used,

something may be malfunctioning inside the PLC. Consult

your local Mitsubishi Electric representative.

6772 EEPROM memory cassette is protected against writing.

The write-protect switch of the EEPROM memory cassette

was set to ON when data was transferred to the EEPROM

memory.

USB communication error [M8487 (D8487)]

8702

Continues

operation

Communication character error

Confirm the cable connection between programming device

and the PLC. This error may occur when a cable is

disconnected and reconnected during PLC monitoring.

8703 Communication data sum check error

8704 Data format error

8705 Command error

8730 Memory access error

When the memory cassette is used, check whether it is

mounted correctly.

If the problem persists or if the memory cassette is not used,

something may be malfunctioning inside the PLC. Consult

your local Mitsubishi Electric representative.

Special parameter error [M8489 (D8489)]

8101

Continues

operation

Special parameter setting time-out error

Turn OFF the power, and check the power supply and

connection of special adapters.

8102 Special parameter setting error

Special parameters are set improperly.

• Confirm troubleshooting for special adapters and set

special parameters correctly.

• Set special parameters correctly, turn OFF the power, and

then turn ON the power.

8103 Special parameter transfer target unconnected error

Special parameters are set, but special adapters/special

blocks are not connected.

Check whether special adapters is connected.

8104 Special parameter unsupported function

Check that special parameters with unsupported settings are

not set for connected special adapters.

Error

code

PLC

operation

at error

occurrence

Contents of error Action