-40-

Model G0747/G0748 (Mfg. Since 8/12)

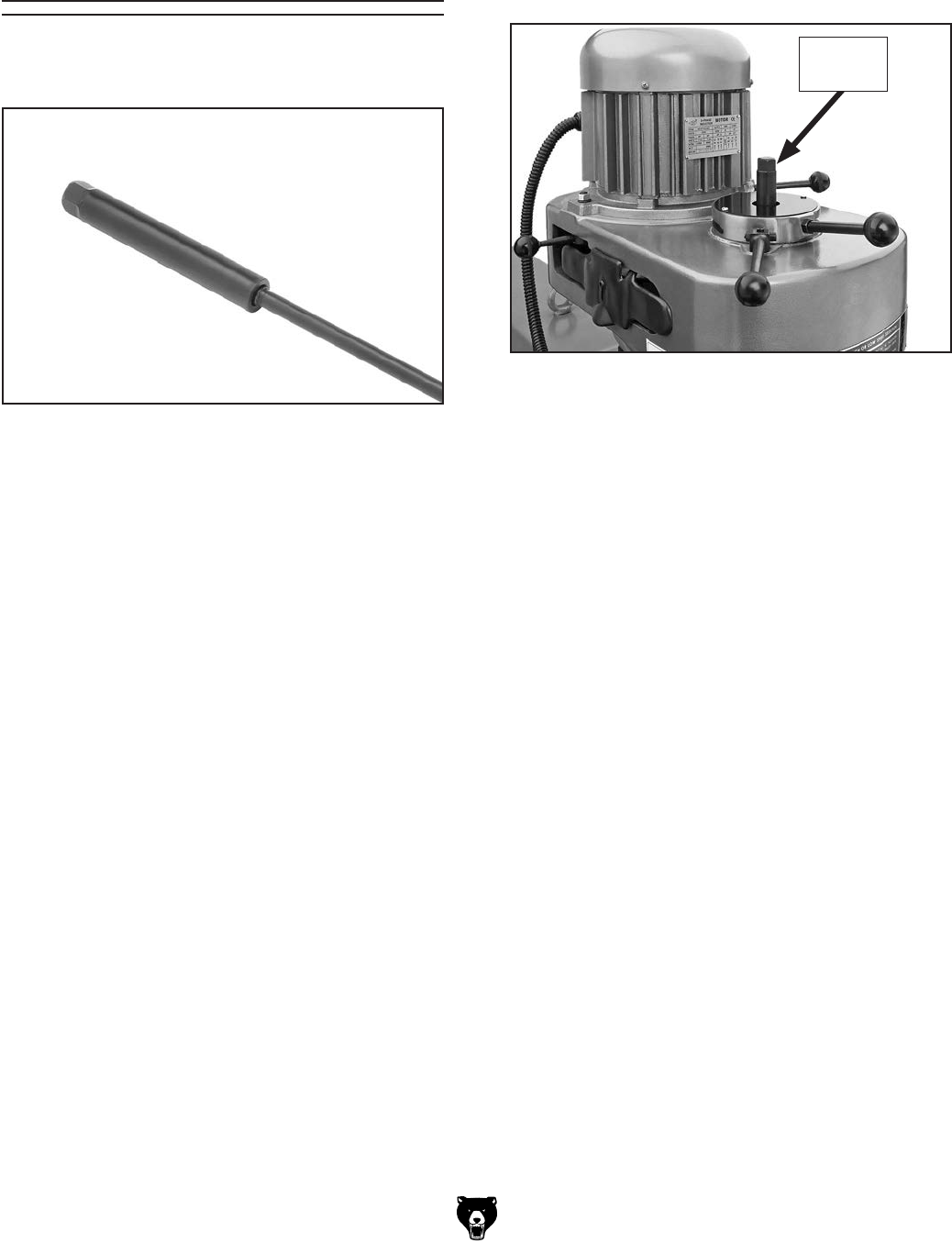

The mill is equipped with an R8 spindle taper and

a

7

⁄16"-20 x 23

1

⁄2" spindle drawbar (see Figure 41).

Tools Needed Qty

Wrench 21mm .................................................... 1

Brass Hammer ................................................... 1

Loading Tooling

1. DISCONNECT MILL FROM POWER!

2. Clean any debris or surface substances from

inside the spindle taper and the mating sur-

face of the tooling.

Note: Debris or oily substances can prevent

the tooling and spindle from properly mating.

This condition can cause excessive vibration,

poor cutting results, or tool/workpiece dam-

age.

3. Place the mill in the low spindle speed range

to keep the spindle from turning in the next

steps.

4. Align the keyway of the tool with the protrud-

ing pin inside the spindle taper, then firmly

push the tool into the spindle to seat it.

Loading / Unloading

To o l i n g

Figure 41. Upper portion of drawbar.

5. With one hand holding the tool in place, insert

the drawbar into the spindle from the top of

the head, then thread it into the tool (see

Figure 42).

6. Tighten the drawbar until it is snug. Avoid

overtightening, as this could make removing

the tool difficult.

Unloading Tooling

1. DISCONNECT MILL FROM POWER!

2. Place the mill in the low spindle speed range

to keep the spindle from turning in the next

step.

Note: Make sure that the drawbar has at

least three threads engaged with the tool-

ing in the next step to avoid damaging the

threads of the drawbar or tool.

3. Loosen the drawbar a couple of turns, then

tap the top of it with a brass hammer to knock

the tool loose at the bottom of the spindle.

4. Support the tool with one hand, then com-

pletely unthread the drawbar from the tool.

Figure 42. Drawbar loaded

(Model G0747 shown).

Head of

Drawbar