-50-

Model G0747/G0748 (Mfg. Since 8/12)

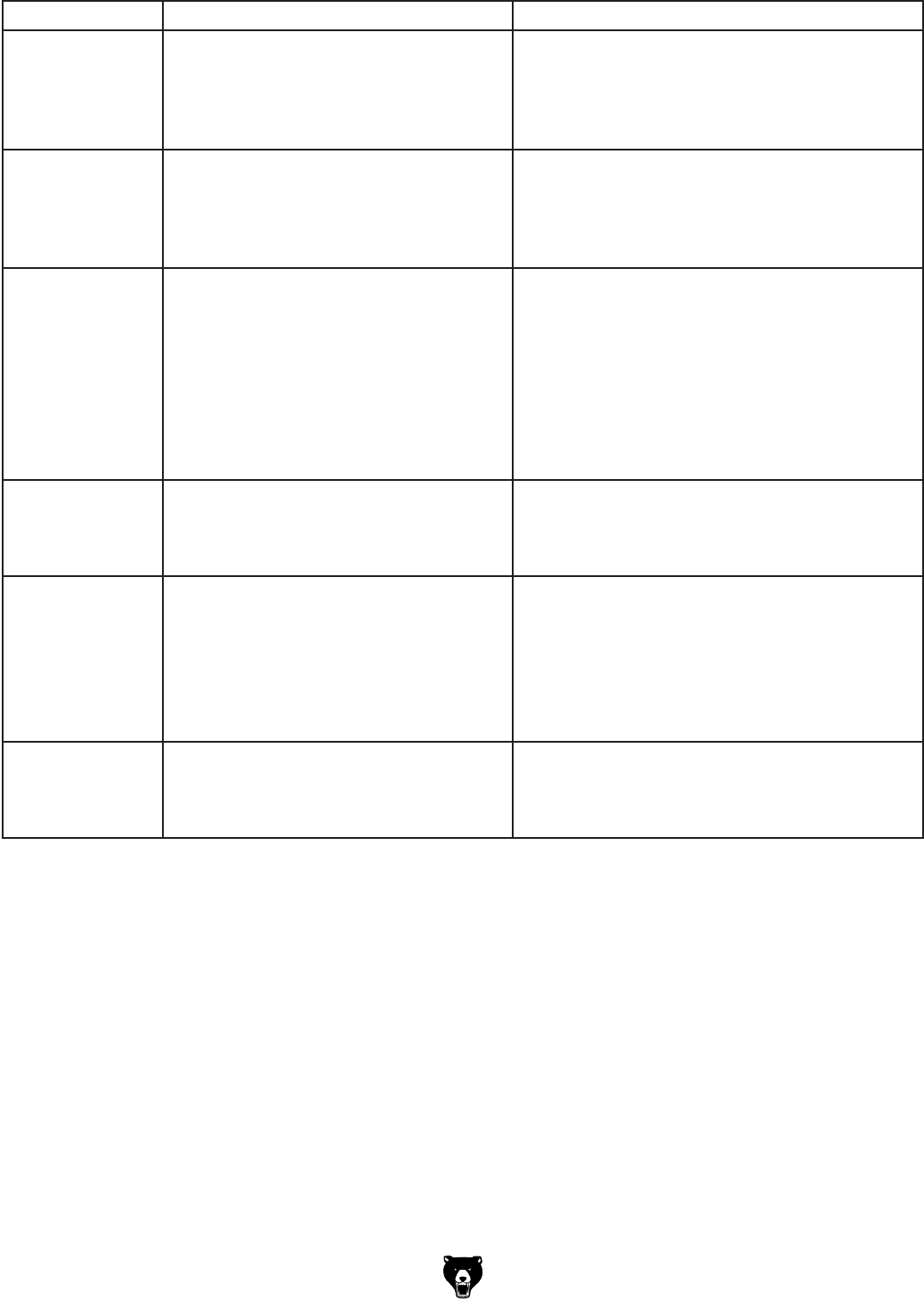

Symptom Possible Cause Possible Solution

Tool slips in collet. 1. Collet not fully drawn into spindle taper.

2. Wrong size collet.

3. Debris on mating surface of collet and

spindle.

4. Excessive depth of cut.

1. Snug up drawbar to fully seat collet.

2. Use correct collet for tool shank diameter.

3. Remove oil and debris from mating surface, then

re-install.

4. Decrease depth of cut and allow chips to clear.

Tool breakage. 1. Spindle speed too slow or feed rate too

fast.

2. Tool getting too hot.

3. Excessive depth of cut.

1. Use correct spindle speed (Page 33 or 35) and feed

rate.

2. Use coolant; reduce spindle speed (Page 33 or 35)

or feed rate.

3. Decrease depth of cut and allow chips to clear.

Workpiece chatters

or vibrated during

operation.

1. Table locks not tight.

2. Workpiece not securely clamped to table or

mill vise.

3. Tool not secure or is damaged.

4. Spindle speed too fast; feed rate too slow.

5. Gibs too loose.

1. Tighten all locks on mill that are not associated with

necessary table movement for the operation.

2. Check that clamping is tight and sufficient for

operation; make sure mill vise is clamped tight to

table.

3. Properly secure the tool; replace if damaged.

4. Use correct spindle speed (Page 33 or 35) and feed

rate

5. Properly adjust gibs (Page 51).

Table hard to move. 1. Table locks are tightened down.

2. Chips have loaded up on ways.

3. Ways are dry and in need of lubrication

4. Gibs too tight.

1. Loosen locks needed for movement.

2. Frequently clean away chips from ways.

3. Use one-shot oiler to lubricate ways (Page 45).

4. Properly adjust gibs (Page 51).

Bad surface finish. 1. Incorrect spindle speed or feed rate.

2. Dull, damaged or incorrect cutting tool.

3. Wrong spindle direction for tool.

4. Workpiece not securely clamped to table or

mill vise.

5. Gibs too loose.

1. Use correct spindle speed Page 33 or 35) and feed

rate.

2. Use sharp and correct cutting tool for operation.

3. Check for correct spindle rotation for tool.

4. Make sure workpiece is properly clamped to table or

mill vise; use work holding jig if necessary.

5. Properly adjust gibs (Page 51).

Power feed chatters

or grinds during

operation.

1. Brass bevel gear is not meshed with drive

gear.

2. Power feed unit at fault.

1. Remove parts from power feed side of X-axis

leadscrew to ensure bevel gear is properly meshed

with drive gear; make sure ball handle nut is snug.

2. Replace power feed unit.