-54-

Model G0747/G0748 (Mfg. Since 8/12)

After positioning the head at an angle and when

your operation requires that the spindle axis be

precisely perpendicular to the table, you must

tram or align the spindle with the table to ensure

the spindle is exactly 90° to the table.

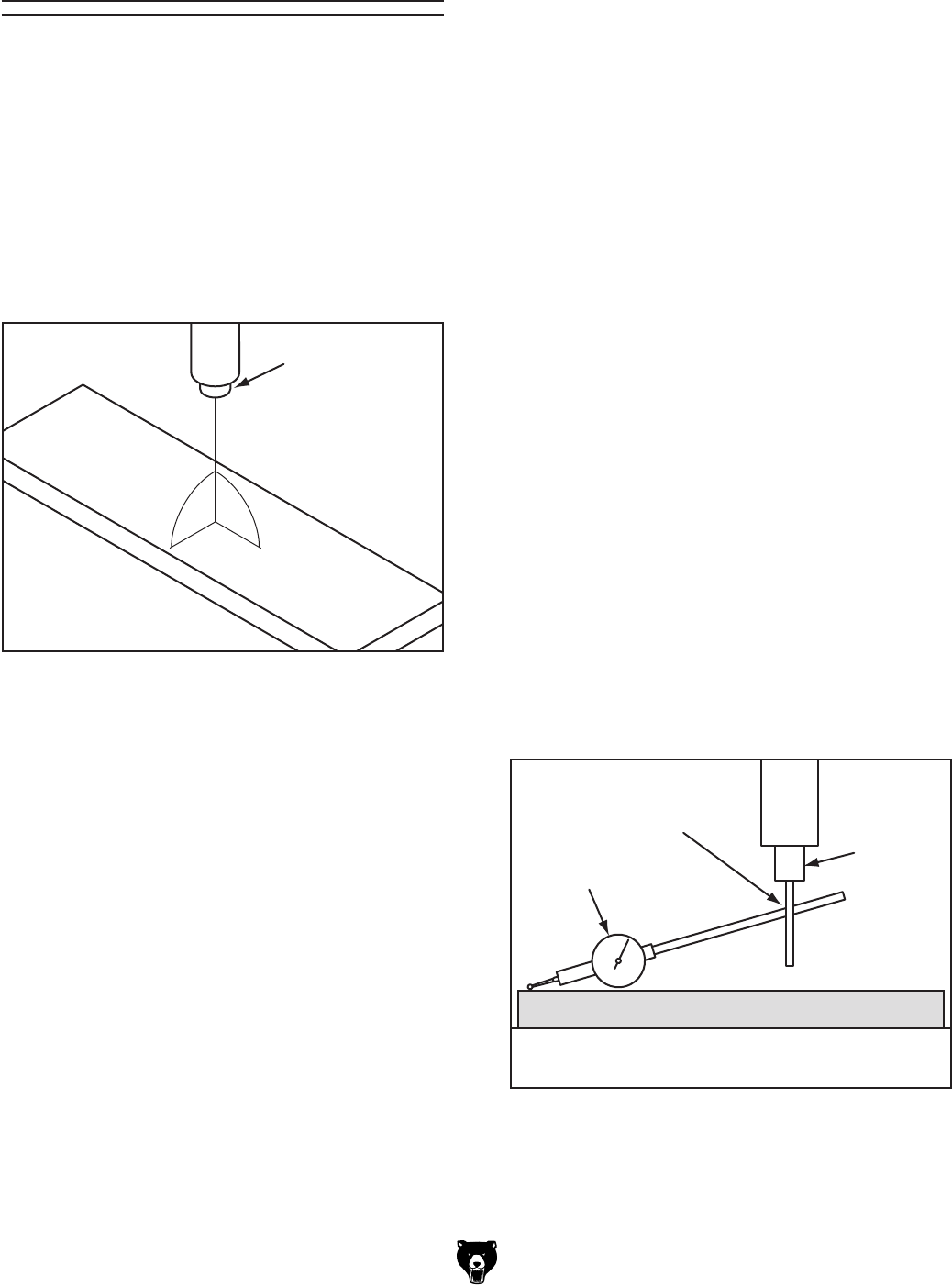

This procedure involves mounting a dial test

indicator to the quill or spindle, rotating it around

the table, and adjusting the spindle axis (Z-axis)

90° to the table X- and Y-axes, as illustrated in

Figure 69.

Table

Spindle

X-Axis

Y-Axis

Z-Axis

90º

90º

Figure 69. Spindle Z-axis perpendicular to the

table X- and Y-axis.

We encourage you to research the many varia-

tions of spindle tramming to find the one that

works best for you. If you do not already have a

preference for performing this operation, use the

following widely-used procedure for accurately

tramming the spindle to the table.

Keep in mind that all workpiece top surfaces are

not exactly parallel with the table top. You may

choose to tram the spindle to the top surface of

the workpiece after it is mounted instead of that

of the table.

Tools Needed Qty

Dial Test Indicator

(with at least 0.0005" resolution) ................. 1

Indicator Holder

(mounted on the quill/spindle) ..................... 1

Precision Parallel Block

(at least 9" in length) .................................... 1

Note: A precision-ground plate can be substi-

tuted for the parallel blocks. Keep in mind that

the farther the indicator point can be placed from

the spindle axis, the more accurate the alignment

measurements will be.

To tram the spindle to the table:

1. DISCONNECT MILL FROM POWER!

2. Prepare the mill for tramming by performing

the following tasks:

• Verify the table is clean by running your

hand over the top of it. If necessary, stone

the table to remove all nicks and burrs,

then clean off all debris.

• Position the table for the milling operation

you intend to perform after tramming—

preferably centered with the saddle.

• Tighten any table, knee, quill, or ram locks

that should be tight during the intended

milling operation.

3. Place the parallel block underneath the spin-

dle.

4. Install the indicator holder in the spindle or on

the quill, then mount the indicator so that the

point is as parallel to the block as possible

(see the illustration in Figure 70).

Tramming Spindle

Table

Spindle

Dial Test

Indicator

Indicator Holder

Parallel Block

Figure 70. Dial test indicator mounted.